In many manufacturing enterprises today, the gluing process is still done manually or semi-automatically. This leads to a series of limitations such as difficulty in controlling the amount of glue, dependence on worker skills, suboptimal productivity and inconsistent quality.

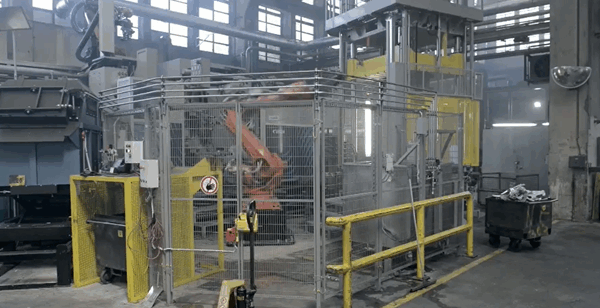

The automatic glue application solution using robots is a breakthrough in automating the production process, bringing accuracy – stability – savings to businesses.

✔ Precise control of glue quantity: Parameters such as pressure, time, and glue quantity are set precisely.

✔ High precision: The robot has a deviation of only ±0.02 mm to ±0.1 mm, ensuring uniform glue spraying quality.

✔ Increase production productivity: Continuously operate according to programming, reduce downtime, improve efficiency.

✔ Save materials: Minimize excess glue, optimize production costs.

Watch a detailed video about the automatic glue application solution using robots here:

With experience in the field of industrial automation, ETEK provides optimal glue application robot solutions that meet international quality standards, helping businesses reduce costs, increase productivity and enhance competitiveness.

ETEK – Accompanying businesses on the path to smart manufacturing automation.

Contact us now for detailed solution consultation!

Our Painting Solution provides an automated system for applying consistent and high-quality coatings to various products, ensuring a smooth and uniform finish every time. This solution is ideal for industries…

In the metal casting industry , the application of industrial robot systems in post-casting processing is becoming an inevitable trend. This solution helps optimize the entire automatic production process from product picking to cooling. 1. Common…

In the era of modern industry constantly developing, automation technology has been reshaping the way manufacturing industries operate, helping businesses improve efficiency and reduce costs. In particular, in the automobile…

What is Riveting Automation? To join parts together, in addition to methods such as screw fastening, welding, or adhesive bonding, people also use the riveting method in specific locations. Riveting…