Coding & Marking Solutions are integral technologies in modern manufacturing, ensuring product traceability, quality assurance, and compliance with industry standards. These solutions involve the application of marks, codes, or labels—such as barcodes, QR codes, production dates, expiration dates, and batch numbers—on product packaging. The goal is to provide critical product information while streamlining processes in manufacturing and supply chain management.

Continuous Inkjet Printers: Continuous Inkjet printers are among the most popular technologies in the field of industrial marking and coding. CIJ systems are renowned for their low cost per print and high uptime, making them ideal for large-scale production operations.

Laser Printers: Laser marking is a cost-effective solution for permanent product identification and traceability. This is a non-contact process that does not require ink and can work on almost any material.

Laser-marked codes are extremely durable and long-lasting, providing sustainable, tamper-proof markings without ink consumption.

Thermal Transfer Printers: Thermal Transfer Printers produce high-resolution prints and use instantly drying ink, enabling fast line-speed coding. They are particularly suitable for printing complex barcodes, text, and graphics on products with irregular shapes.

Automatic Labeling Machines: Automatic labeling machines are designed to precisely apply labels onto products such as bottles, boxes, or other packaging types at high speeds. These machines minimize labor costs by automating the labeling process and ensuring consistent placement.

Large-Format Labeling Machines: Large-format labeling machines are specialized for oversized products or bulky packaging. They ensure consistent label placement on large surfaces, such as pallets, crates, or industrial-sized containers, without compromising speed or accuracy.

Advanced Camera Systems: Verification systems employ high-resolution cameras and advanced sensors to inspect printed codes and labels for accuracy, quality and scannability. These systems detect errors such as smudged prints, misaligned labels, or incorrect data, ensuring compliance with industry standards.

Defect Detection and Rejection: By automatically identifying defective products, verification systems help reduce manual quality checks, minimize errors, and enhance production efficiency. Products that fail to meet quality requirements are removed from the line, ensuring only compliant items proceed to the next stage.

Compliance and Traceability: These systems play a critical role in regulatory compliance and product traceability by ensuring that all codes and labels meet required standards. They also store inspection data for auditing purposes, enhancing transparency across supply chains.

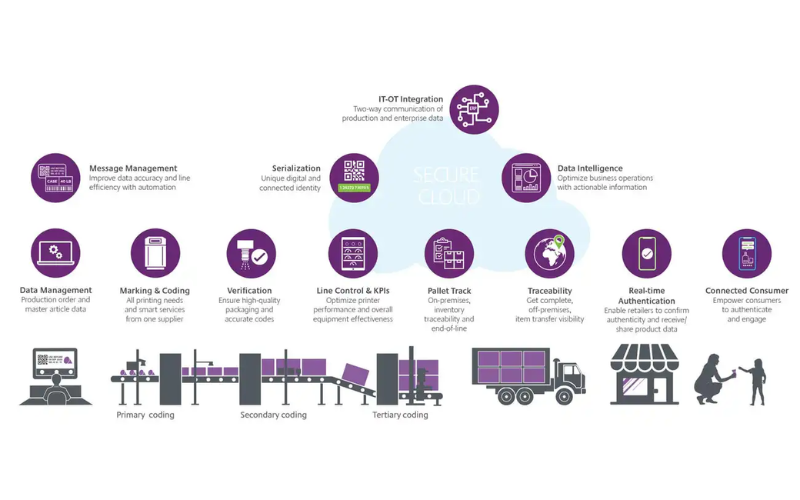

Seamless Production Line Integration: Modern coding and marking solutions are designed to integrate seamlessly with existing production lines, ensuring smooth operations without requiring extensive modifications. They can be synchronized with conveyors, robotics, and packaging equipment to optimize workflows.

MES and ERP System Connectivity: Integration with Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) software allows for real-time data sharing across production units. This synchronization improves inventory management, production planning, and overall operational visibility.

With nearly 20 years of experience in industrial automation, ETEK delivers cutting-edge Coding & Marking Solutions tailored to meet the needs of various industries. ETEK offers:

By adopting Coding & Marking Solutions, manufacturers can enhance product quality, operational efficiency, and brand trust, ensuring they remain competitive in a dynamic global market.

Continuous Inkjet (CIJ) printers are non-contact printing technology widely used in modern industrial production lines due to their high precision and fast speeds. These printers are ideal for printing codes…

A thermal transfer printer ( also known as a TTO - Thermal Transfer Overprinting machine) is a device that uses thermal transfer technology to print on packaging surfaces or other…

Modern laser engraving machines have become indispensable tools in various manufacturing and processing industries due to their ability to cut, engrave, and mark with exceptional precision and speed. This technology…

A large Continuous inkjet printer is a specialized device designed to print large-sized products such as banners, posters, billboards, and other promotional materials. Capable of printing on various materials such…

What is CoLOS Software? CoLOS software is an intelligent solution designed to manage and optimize printing and coding activities on packaging. With its comprehensive integration capabilities, the software helps businesses…

An automatic labeling machine is a device designed to print and apply labels directly onto products and packaging as they move along a conveyor. These machines integrate bot printing and…