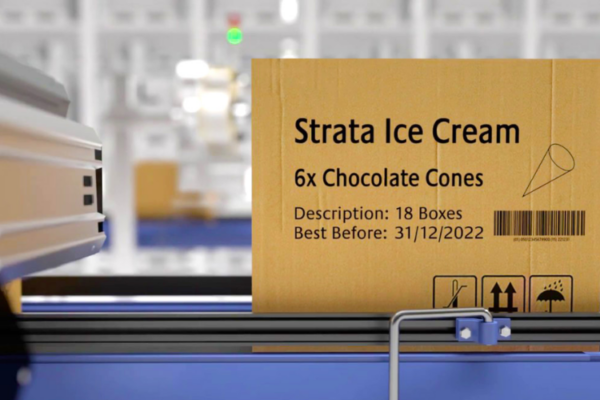

A thermal transfer printer ( also known as a TTO – Thermal Transfer Overprinting machine) is a device that uses thermal transfer technology to print on packaging surfaces or other materials. Unlike traditional liquid ink printing, thermal transfer printers use a ribbon to transfer heat onto the printing surface. This results in sharp, durable prints on various materials such as plastic, paper and composite materials.

Thermal transfer technology operates based on the principle of transferring heat from a ribbon onto the surface of the material to be printed.

The heat source warms up the ribbon, causing the ink to adhere to the material and create the necessary images, characters, barcodes or printed information.

TTO printers can adjust the temperature and printing speed to suit different material types and product requirements, ensuring the quality and durability of the prints.

Industrial thermal transfer printers have a wide range of applications in manufacturing and packaging industries. Some of the key applications include:

Using thermal transfer printers in production helps businesses improve the efficiency and accuracy of the printing process. TTO printers offer several benefits, including:

Coding & Marking Solutions are integral technologies in modern manufacturing, ensuring product traceability, quality assurance, and compliance with industry standards. These solutions involve the application of marks, codes, or labels—such…

Continuous Inkjet (CIJ) printers are non-contact printing technology widely used in modern industrial production lines due to their high precision and fast speeds. These printers are ideal for printing codes…

Modern laser engraving machines have become indispensable tools in various manufacturing and processing industries due to their ability to cut, engrave, and mark with exceptional precision and speed. This technology…

An automatic labeling machine is a device designed to print and apply labels directly onto products and packaging as they move along a conveyor. These machines integrate bot printing and…

A large Continuous inkjet printer is a specialized device designed to print large-sized products such as banners, posters, billboards, and other promotional materials. Capable of printing on various materials such…

What is CoLOS Software? CoLOS software is an intelligent solution designed to manage and optimize printing and coding activities on packaging. With its comprehensive integration capabilities, the software helps businesses…