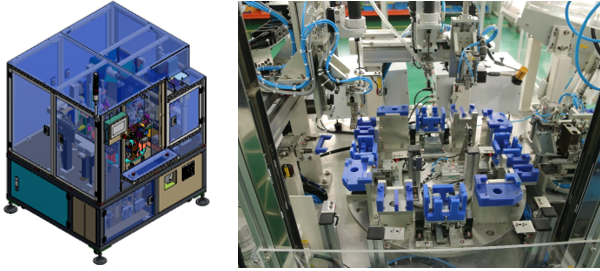

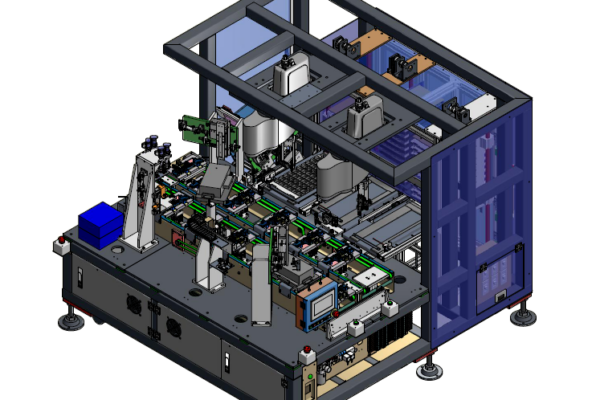

Our Assembly Solution is designed to enhance production efficiency, accuracy, and output while minimizing human intervention. By integrating advanced robotics, automated conveyance, and vision-guided technology, the system ensures precision in complex assembly processes. Additionally, this solution is adaptable to various industries, particularly those requiring high precision and speed, such as automotive, electronics, and consumer products manufacturing.

Furthermore, by automating assembly tasks, the system significantly reduces manual errors, labor costs, and production downtime. As a result, it becomes an ideal solution for companies looking to streamline their manufacturing processes and improve overall performance.

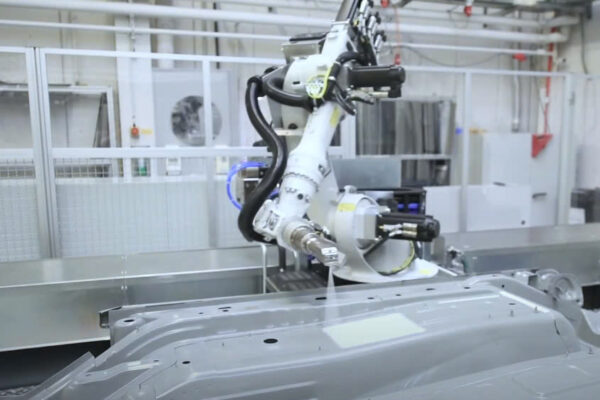

ETEK has integrated automated automotive assembly lines in Vietnam and neighboring countries such as India and Indonesia. Using material handling systems, robotics, and vision, we can help you create ergonomic and efficient product lines that protect human workers from hazardous conditions while completing assembly quickly. Our automotive assembly experience includes:

Similar to the automotive industry, the electrical and electronics industries have adopted automation at growing rates. Companies have deployed robotics, vision, and artificial intelligence for welding, assembly, and material handling to increase cycle rates and improve worker safety. These integrations have improved the manufacturing and assembly of all parts of aircraft, ammunition, and weaponry. Our automotive assembly experience includes:

Our assembly solution helps companies automate their production processes to achieve higher efficiency and accuracy. Whether you are manufacturing complex automotive components or assembling small electronics, our system adapts to your needs. With industry-proven results in sectors like automotive, electronics, and consumer goods, we offer a solution that drives productivity, reduces costs, and delivers superior product quality.

This Assembly Solution is perfect for businesses aiming to scale their production while maintaining high standards of quality and precision in every step of the assembly process.

We have the expertise to join, press, fasten, rivet or weld your components together into their final form, whether you load the parts manually or feed them into our system.

| Adhesive & sealant dispensing | High-speed pick & place | Insert assembly | Riveting |

| Adhesives | Impact riveting | Joining | Robotic assembly |

| Assembly | Press tending | Leak testing | Robotic palletizing |

| Bowl feeding | Pressing | Silicon welding | Screw driving |

| Case packing | Lot traceability | Sonic welding | Vision inspection |

| Clinch riveting | Clip driving | Medical packaging | Smart factory |

What is Gluing Automation? Since ancient times, people have known how to bond materials, seal, or protect surfaces by manually applying, spreading, or spraying adhesive using simple tools. This traditional…

What is Riveting Automation? To join parts together, in addition to methods such as screw fastening, welding, or adhesive bonding, people also use the riveting method in specific locations. Riveting…

What is Screwiing Automation? In the past, before automation technologies were developed, screwing was primarily done manually using simple tools that relied on human labor, such as screwdrivers, handheld screw…

What is Automation Inserting? In our daily lives, we frequently encounter products assembled from numerous components, such as TVs, phones, laptops, and computers. The assembly process of these products involves…

What is Sealing? Sealing is the process of creating a protective layer or barrier to prevent the intrusion or leakage of liquids, gases, dust, or other contaminants between surfaces or…

Years

Talented Employees

The fastest company in Vietnam

Location Worldwide

Fill out the form or give us a call for Consultation

Email us: info@etek.com.vn

Call us: (+84) 965 800 166