To join parts together, in addition to methods such as screw fastening, welding, or adhesive bonding, people also use the riveting method in specific locations. Riveting is the preferred choice for thin materials that are prone to deformation when exposed to high temperatures, making welding impossible, while still requiring a solid structure.

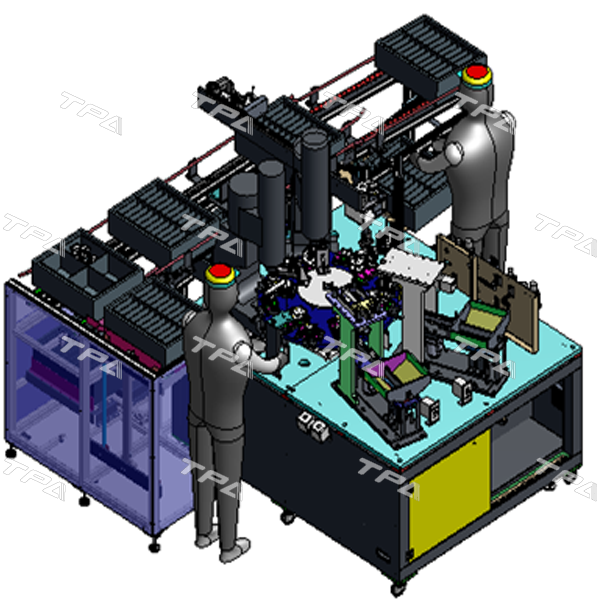

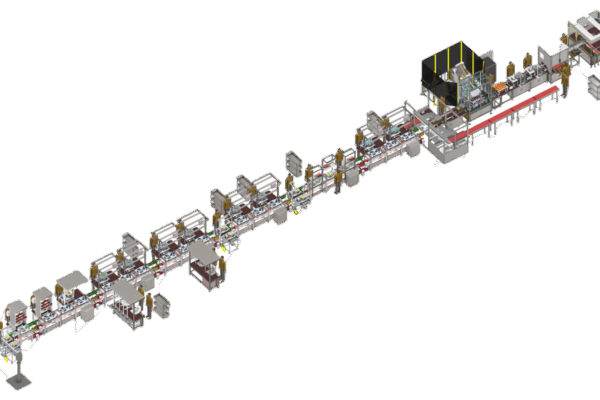

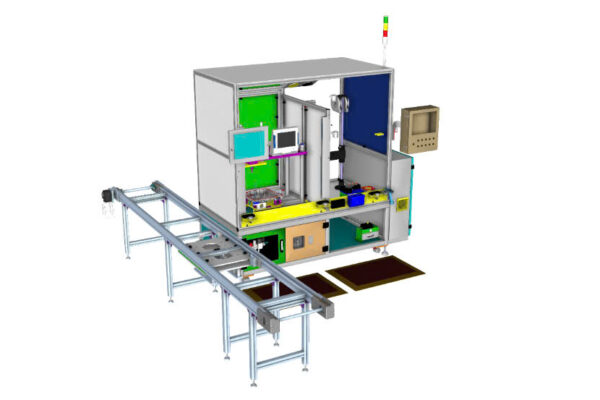

To increase productivity, automation solutions have been implemented to replace manual labor. Automated systems (robots, machinery, control devices, sensors) are used to perform riveting tasks in parts or products without human intervention. Riveting automation technology enhances efficiency, precision, and reduces errors during assembly.

A riveting automation system typically includes the following components:

With the superior benefits offered by riveting applications, combined with automated systems, many significant advantages arise:

To keep pace with the rapidly changing needs of society, many assembly industries have adopted riveting automation in production. Common applications include the following industries:

The application of riveting automation is not only a trend but an inevitable factor in meeting the needs of modern production. Thanks to its superior benefits in productivity, quality, labor safety, and flexibility, riveting automation has become an essential solution in industries such as automotive, aerospace, machinery manufacturing, electronics, and other manufacturing fields. With the continuous development of science and technology, riveting automation will continue to play an important role in improving production efficiency and maintaining competitiveness in the global market.

The exponential growth of the electric motorcycle and electric vehicle industry demands increasingly sophisticated standards for high-volume productivity, precision manufacturing, and stringent quality control across all battery production processes. At…

In industrial production lines, every assembly step plays a vital role in ensuring the quality of the final product. One of the key steps is pin pressing, which helps secure…

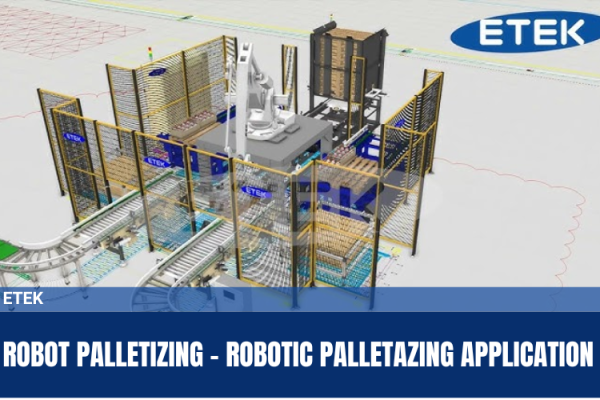

In industrial production, one of the stages prioritized for automation is the loading and unloading of go ods... From now on, businesses should turn automation solutions into their competitive advantage…

The Pick to Light system integrated into automotive assembly plants is an efficient solution that helps workers quickly and accurately select components, reducing errors and improving productivity. Understanding the Pick…