In the era of Industry 4.0, the electronics manufacturing sector is facing increasing pressure in terms of speed, precision, and operational efficiency. To meet these demands, Autonomous Mobile Robots (AMRs) have emerged as a smart automation solution, enabling businesses to optimize warehouse management and production lines

At a large-scale electronics manufacturing plant, the AMR system has been successfully deployed with impressive results:

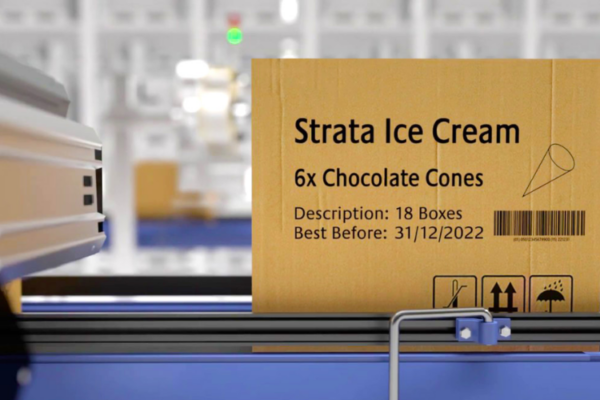

Coding & Marking Solutions are integral technologies in modern manufacturing, ensuring product traceability, quality assurance, and compliance with industry standards. These solutions involve the application of marks, codes, or labels—such…

How Automation Works in the Food and Drink Industry Automation in the food and drink industry involves the application of technology to various production stages. Automation in food processing demands…

Introduction to Kardex Smart Warehouse The application of advanced technology in warehouse management has become an inevitable trend to enhance efficiency and reduce costs. Therefore, Kardex—with its long-standing history and…

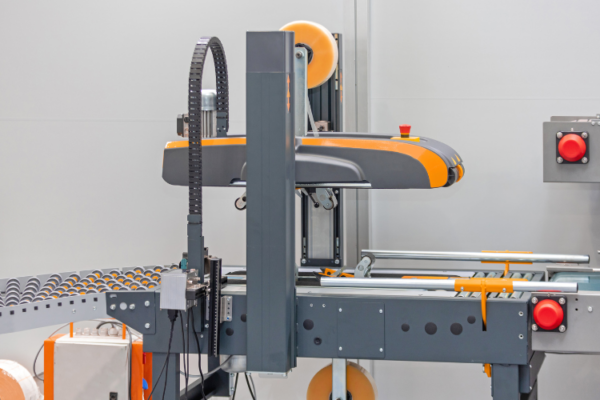

In modern production processes, ensuring that cartons are securely, aesthetically, and efficiently sealed is a critical factor in improving product quality and optimizing packaging lines. The case sealer (carton sealing…