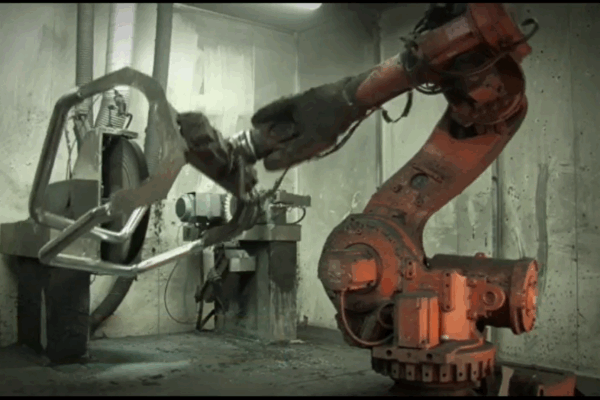

Our Welding Solution offers an advanced, fully automated system for performing a wide range of welding tasks with precision and consistency. This solution is ideal for industries that require strong, durable welds in high-production environments, such as automotive, metal fabrication, and heavy machinery. Utilizing robotic welding arms, multi-axis systems, and welding control software, we ensure that every weld is executed with the utmost accuracy, reducing manual errors and improving overall production efficiency.

With the ability to handle various welding processes—such as MIG, TIG, and spot welding—our solution adapts to the specific needs of different industries, ensuring the highest quality joints and minimizing rework.

Our welding solution is widely applicable across industries that require precision and strength in welded joints, especially in high-volume production environments:

Our Welding Solution is designed to deliver precision, speed, and quality in welding operations. By integrating advanced robotic systems, welding control platforms, and real-time monitoring technologies, we help manufacturers automate their welding processes for maximum efficiency and consistency.

Whether you are welding components for the automotive, metal fabrication, heavy machinery, or aerospace industries, our solution ensures high-quality, durable welds with every operation. It’s an essential tool for businesses looking to improve production speed, reduce errors, and enhance workplace safety.

With proven success across various industries, our welding solution is the key to optimizing your welding processes while ensuring top-tier product quality and reliability.

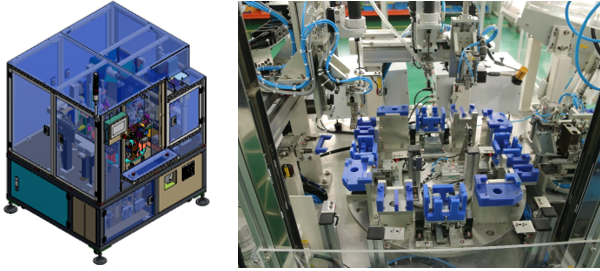

We have experience in successfully implementing various welding solutions for businesses in the fields of electronics, automotive, motorcycles, and more. We have provided TIG welding, MIG welding, spot welding, and other solutions. Our provided systems have operated stably and achieved high productivity.

What is Screwiing Automation? In the past, before automation technologies were developed, screwing was primarily done manually using simple tools that relied on human labor, such as screwdrivers, handheld screw…

To maximize the flexibility of ABB's robotic welding cells, the automotive parts manufacturing plant quickly installed 27 FlexArc robots to respond faster to end customer needs while maintaining cost efficiency.…

The case packer machine is a modern solution designed to optimized the automatic packaging process for bagged products. With its quick, precise and flexible operation, the machine not only increases…

In the context of the automobile industry increasingly moving towards automation and high quality , the application of car bumper polishing robots has become an inevitable trend to help businesses improve productivity, optimize costs…