The metal industry is one of the most versatile industries and is therefore identified as a priority for robot-based automation solutions. This sector demands perfection in minor details and top performance in challenging, sometimes extremely harsh, working conditions.

In recent years, we have observed an increasing demand for automation solutions in the metal industry and have responded quickly. Our automation solutions are gradually replacing manual processes or less flexible automated processes. Our automation solutions include TIG welding, MIG welding, spot welding, stamping solutions, aluminum casting, and processing solutions such as milling, cutting, folding, grinding, deburring, etc.

To optimize automation solutions, the application of robots to replace human labor in the production process is essential. With the continuous advancement of modern technology and artificial intelligence, robots can handle most tasks within the production workflow.

Over the past 50 years, many industries have implemented automation in manufacturing, leading to the current state, especially in the automotive industry. Automakers like Ford, Mercedes, Toyota, Honda, and Nissan, … have all adopted automated production and assembly lines, with welding robots playing a significant role. Leading this trend in Vietnam is VinFast.

We are a unit that can provide solutions related to:

Automation in the metal industry offers five practical benefits as follows:

The advanced AGV/AMR robotics technology is revolutionizing factory and warehouse operations, optimizing logistics efficiency, and enabling the safe and fast movement and storage of goods. By automating the entire transportation…

Continuous Inkjet (CIJ) printers are non-contact printing technology widely used in modern industrial production lines due to their high precision and fast speeds. These printers are ideal for printing codes…

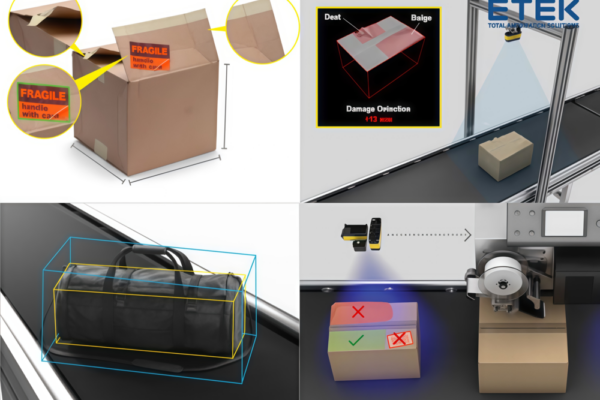

The 3D-A1000 dimensioning system is a compact industrial smart camera capable of capturing moving objects in both 2D and 3D. It is equipped with powerful vision tools that enable automation…

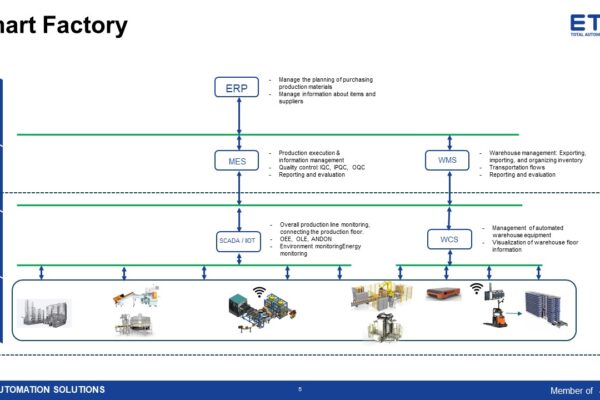

A smart factory is no longer just a trend but has become the new standard in modern manufacturing. It is a production facility that leverages advanced technologies such as IoT…