Water heaters are essential appliances in every modern household, requiring precise, safe, and consistent manufacturing processes. With extensive experience in production automation, ETEK provides automated water heater assembly line solutions that help businesses increase productivity and optimize operational costs.

Our water heater assembly line specializes in manufacturing residential water heaters including both wall-mounted and floor-standing models, serving the consumer electronics and large-scale home appliance assembly industries. The system is also adaptable for similar products requiring PU thermal insulation, electronic component assembly, and mechanical assembly processes. This versatility makes our solution ideal for manufacturers in the consumer electronics sector focusing on home appliances, as well as companies producing related products that require precision thermal insulation, automated component integration, and high-volume production capabilities with consistent quality standards.

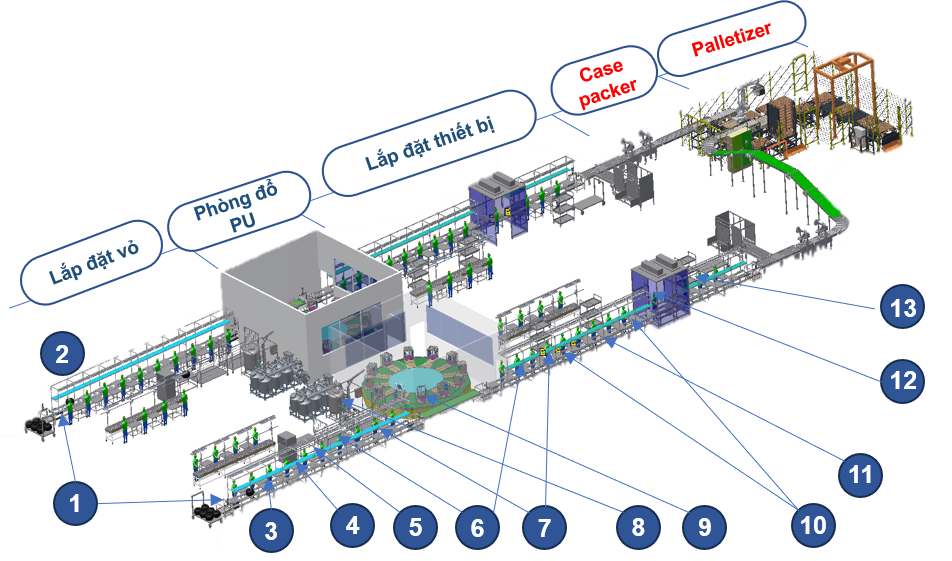

The assembly line is designed with multiple integrated zone clusters, including housing assembly, PU injection room, equipment installation, case packer, and palletizer:

1. Inner Tank Inspection: Automated verification of tank shape and airtightness using precision measurement systems and pressure testing equipment.

2. Heating Element and Anode Rod Installation: Robotic mounting of heating elements and anode rods internally with torque-controlled fastening and positioning verification systems.

3. Product Labeling: Automated application of specification and brand labels using precision positioning systems with vision verification and quality control.

4. Airtightness Testing: Comprehensive pressure measurement and gas leak detection using advanced testing equipment with automated pass/fail classification systems.

5. Outer Housing Screw Fastening: Automated installation and securing of protective plastic housing using multi-spindle screwdriving systems with torque monitoring.

6. Internal Fastening Bolts: Precision securing of internal components within the tank using robotic assembly systems with force feedback control.

7. Flash Removal: Automated cleaning of plastic surface flash using precision cutting tools and surface finishing equipment for optimal appearance.

8. PU (Polyurethane) Injection: Controlled pumping of PU foam to create thick thermal insulation layer using automated dispensing systems with flow monitoring.

9. PU Drying: Temperature-controlled heat treatment for complete PU curing using automated conveyor ovens with precise time and temperature control.

10. Final Screw Fastening: Automated installation of remaining components and screws using multi-station assembly systems with integrated quality verification.

11. Final Bolt Securing: Comprehensive final inspection and tightening using torque-controlled systems with automated verification of all fastener specifications.

12. Technical and Electrical Testing: Automated resistance measurement and functional verification using integrated testing equipment with comprehensive safety and performance validation.

13. Product Polishing and Cleaning: Automated cleaning and polishing of tank exterior using robotic systems with surface quality inspection and final appearance verification.

Refer to ETEK’s completed projects HERE

Let ETEK partner with you from assessment – design – manufacturing – installation – technology transfer.

Address: 189 Phan Trong Tue Street, Thanh Liet Ward, Thanh Tri District, Hanoi, Vietnam

Hotline: 0965800166

Email: info@etek.com.vn

Website: https://etekautomation.com.vn

The 3D-A1000 dimensioning system is a compact industrial smart camera capable of capturing moving objects in both 2D and 3D. It is equipped with powerful vision tools that enable automation…

https://www.youtube.com/watch?v=CueLwlbNOeQ Challenges in Traditional Warehouse Management In today’s increasingly competitive environment, manufacturing and logistics companies are facing numerous challenges in warehouse management: Warehouses are full but still short of space:…

Our Stamping Solution provides an efficient, high-speed method for producing stamped components from metal and plastic materials. Using automated stamping machines, robots, sensors, vision systems, conveyors, etc., to meet the…

In the context of the electronics industry increasingly requiring flexibility, speed and high quality, ETEK introduces a semi-automatic LCD screen assembly line solution , applying the advanced Collaborative Automation model -…