The robotic arm is programmed to perform a specific task. Additionally, the joints move along the axis of rotation in a certain number of directions. As a result, it follows the principle of working similarly to the human hand.

The robot arm includes: operator arm, gripper, control system, drive, sensor system.

Robotic arms typically feature several flexible joints, which allow them to move and rotate in various directions. Servo motors control these joints, enabling the robotic arm to perform operations with accuracy and speed.

Depending on the application and intended use, robotic arms can be designed with specialized tools, such as clamps, handles, or cutters and grinders. These tools make the robotic arm able to perform tasks such as metalworking, product assembly, and even surgery.

Industrial robotic arms are compact, lightweight devices that will work well in even tight spaces. That helps save space in factories and production workshops. These amazing products will continue to be widely used in the years to come. It delivers many times more accuracy and productivity. The robot will be improved and enhanced over time. Therefore, all of the above benefits will continue to be developed.

FOR MORE INFORMATION, PLEASE CONTACT ETEK AUTOMATION SOLUTIONS JOINT STOCK COMPANY

What is Delta robot? Robot delta (Spider Robot) is a line of robots with a distinct design compared to other stationary industrial robots. The name delta comes from its inverted…

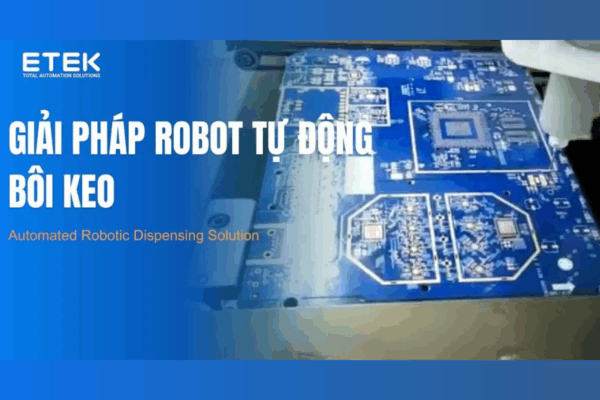

In electronics manufacturing, especially in PCB processing, manual glue dispensing or protective coating often faces many limitations: smudging, lack of precision, heavy reliance on worker skills, and difficulties in quality…

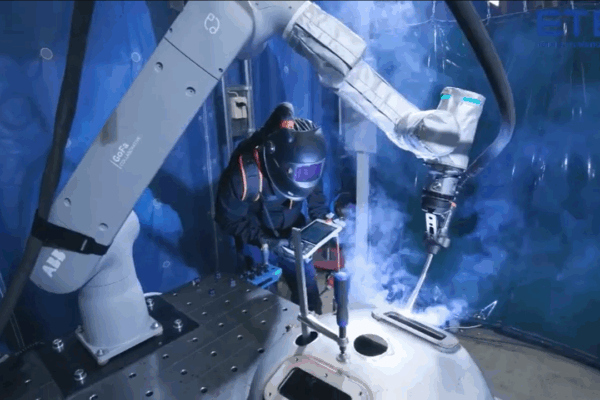

In the industrial kitchen equipment manufacturing industry, the quality of the weld not only determines the durability and safety but also directly affects the aesthetics of the product. In particular,…

Smart warehouses is a storage system that utilizes advanced technologies such as automation, the Internet of Things (IoT), Artificial Intelligence (AI), and Big Data to efficiently and accurately manage storage,…