The 3C electronics industry requires ultra-fast manufacturing solutions that deliver exceptional speed, precision, and reliability. ETEK Automation provides comprehensive printer power supply assembly line systems that integrate cutting-edge automation technology to meet the demanding requirements of high-volume electronics production.

Power Supply Units for:

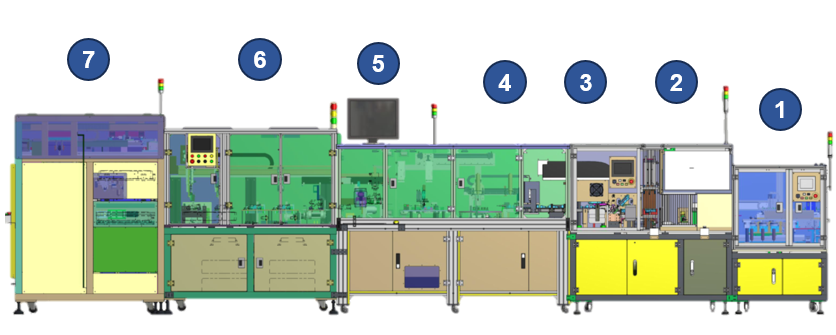

Our state-of-the-art automated assembly line is built around a streamlined 7-step workflow, engineered to deliver high-speed production without compromising on precision or product quality. Each stage is carefully optimized to ensure consistency, reliability, and scalability for high-volume manufacturing:

PCB Routing

The process begins with automated circuit board separation, where PCBs are accurately routed and cut from larger panels. This step ensures each board is cleanly prepared for the downstream operations, with minimal mechanical stress or defects.

PCB Mounting

Using advanced vision-guided systems, PCBs are precisely positioned and mounted into their designated housings. This guarantees proper alignment and secure placement, forming the foundation for all subsequent assembly steps.

Assembly

Components such as connectors, sensors, or structural parts are seamlessly integrated into the product through robotic arms and pick-and-place systems. Each part is positioned with micron-level accuracy to ensure functional reliability.

Laser Engraving

High-speed laser systems engrave serial numbers, QR codes, logos, and other identifying marks onto the product surface. This not only supports branding but also enables traceability and compliance with industry standards.

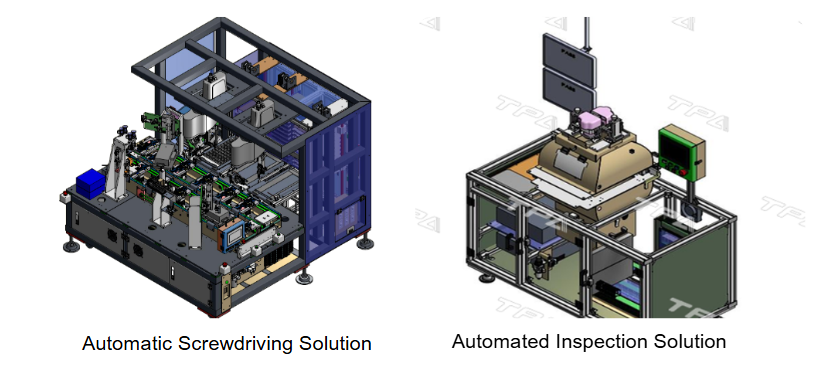

Screw Fastening

Automated screwdrivers perform precision fastening of the housing and internal components. With torque monitoring and quality control feedback, this step ensures structural integrity and long-term durability.

Aging Tests

Every assembled unit undergoes rigorous functional and environmental testing. These aging tests simulate real-world operating conditions to detect early failures and ensure that only high-performance, stable products reach the market.

Packaging

In the final stage, products are automatically inspected, labeled, and packaged according to customer requirements. Protective materials and anti-static handling are applied where necessary, ensuring the product is ready for secure shipment and delivery.

ETEK Automation delivers ultra-high-speed electronics manufacturing systems with advanced PCB handling, precision laser engraving, and comprehensive aging test capabilities. Our solutions integrate automated routing systems, high-speed assembly robotics, and intelligent quality control to ensure efficient, reliable power supply production that meets 3C industry standards.

Refer to ETEK’s completed projects HERE

Transform your electronics manufacturing capabilities with ETEK’s ultra-fast automation solutions. Our expert team provides complete support from design consultation through implementation and maintenance.

Contact ETEK Automation Today:

Address: 189 Phan Trong Tue Street, Thanh Liet Ward, Thanh Tri District, Hanoi, Vietnam

Phone: 0965800166

Email: info@etek.com.vn

Website: https://etekautomation.com.vn

In modern manufacturing, optimizing processes and increasing production speed have become essential requirements. The application of automation technology in packaging helps businesses reduce reliance on manual labor, improve accuracy, and…

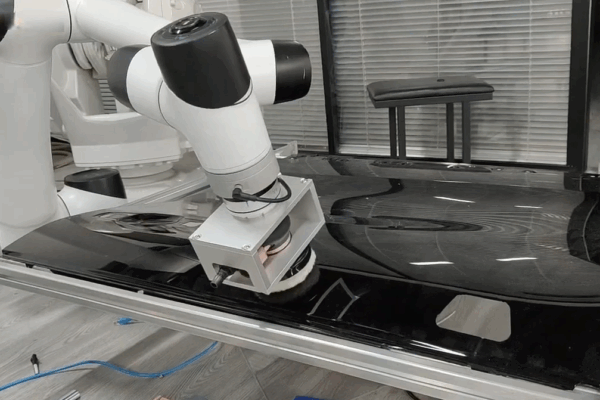

In the automotive industry, polishing plays a key role in ensuring that the product surface meets perfect standards before entering the next stages such as painting, assembly or shipping. Robotic polishing…

The automatic screwdriving cobot solution for automated assembly lines enables safe human–robot collaboration without the need for safety fences, ensuring high precision, stable productivity, continuous operation, and ease of use.…

What is automation in the metal industry? The metal industry is one of the most versatile industries and is therefore identified as a priority for robot-based automation solutions. This sector…