The advanced AGV/AMR robotics technology is revolutionizing factory and warehouse operations, optimizing logistics efficiency, and enabling the safe and fast movement and storage of goods. By automating the entire transportation process, AGV/AMR robots not only save time but also significantly reduce operational costs for businesses.

AGVs (Automated Guided Vehicles) and AMRs (Autonomous Mobile Robots) enhance logistics performance by safely transporting and storing goods in factories and warehouses.

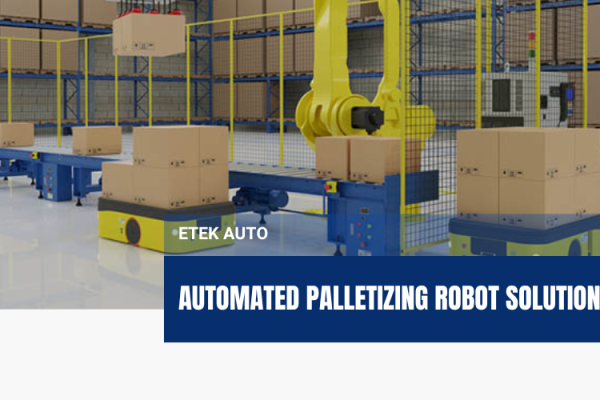

ETEK offers optimal AGV/AMR solutions for production, storage, and goods distribution needs.

ETEK provides AGV/AMR robots suitable for all production processes and customer requirements, including autonomous mobile robots, automated pallet stackers, narrow-aisle forklifts, counterbalanced forklifts, and conveyors capable of moving multiple pallets simultaneously.

For applications requiring high customization, ETEK develops tailored solutions by integrating specialized tools and equipment for AGVs.

With ETEK’s AGV/AMR robots, your business not only saves costs and enhances operational efficiency but also improves safety and flexibility in warehouse management. Let ETEK accompany you on your journey toward automation and sustainable development!

The surface treatment industry, also known as surface processing, is a diverse and important industrial field that involves creating surfaces with different properties to meet the requirements of various applications.…

Palletizing robots and pallet-stacking robots are becoming increasingly important in manufacturing plants, effectively fulfilling the final task of automated line for stacking goods onto various types of pallets. The application…

Are you looking for an automated confectionery packaging solution where pick-and-place robots operate with precision, box sealing systems work efficiently and the entire process runs smoothly with a high level…

Palletizing is the process of loading products onto pallets on demand. In the final stage of the packaging line, the robot performs the task of bagging, the robot loads the…