A smart warehouse is a modern storage facility designed to store raw materials and manufactured goods. It leverages machinery and technology to replace traditional warehousing tasks previously performed by humans.

These tasks include order receipt and processing, product counting, goods storage and location tracking, as well as transporting orders to their designated locations. The most efficient smart warehouses today automate nearly the entire operational process—from receiving goods to delivering them to customers with minimal errors.

Smart warehouses are modeled on smart factories, featuring an automated and tightly interconnected data environment. These facilities use a variety of automation technologies to create a system where goods and orders can be received, sorted, organized, and prepared for delivery without human intervention. By integrating these technologies, smart warehouses enhance productivity, quality, and operational efficiency while reducing errors and labor requirements.

In traditional warehouses, manual tasks such as inspection, recording, and inventory management are prone to errors and time-consuming. Smart warehouses automate these processes, significantly minimizing human-induced errors. Orders are processed quickly through interconnected systems that verify inventory status and generate transportation routes in just seconds.

Automated robots and intelligent warehouse management systems optimize the sorting, storage, and transportation of goods. Products are swiftly and accurately transported to designated locations, boosting operational speed and saving time.

Smart warehouses operate on advanced technologies such as robotics, the Internet of Things (IoT), and Artificial Intelligence (AI), replacing humans in tasks like inventory management and product location tracking.

When an order is received, the system verifies the goods and sends a pick list to the robots. The robots locate and deliver the products to packing staff. Smart warehouses ensure flexibility, scalability, and real-time data visibility to meet operational demands efficiently.

Smart warehouses not only optimize processes but also improve productivity, reduce errors, and help businesses adapt to rapidly changing market conditions.

With capabilities such as on-demand production and instant delivery, smart warehouses bridge the gap between storage facilities and factories. Cutting-edge technologies like collaborative robots and 3D printing create opportunities for businesses to boost productivity, swiftly meet customer demands, and gain a competitive edge.

Don’t miss the chance to elevate your business competitiveness! Smart warehouses are not just a solution for today—they are the key to leading future trends. Start investing today and move forward with technology!

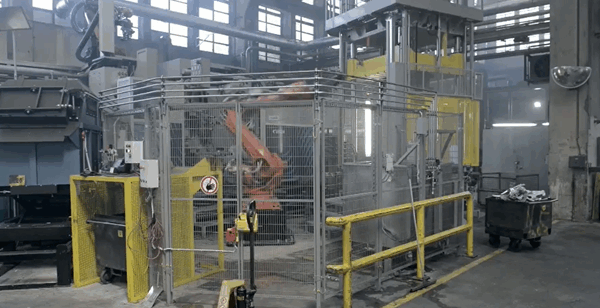

In the metal casting industry , the application of industrial robot systems in post-casting processing is becoming an inevitable trend. This solution helps optimize the entire automatic production process from product picking to cooling. 1. Common…

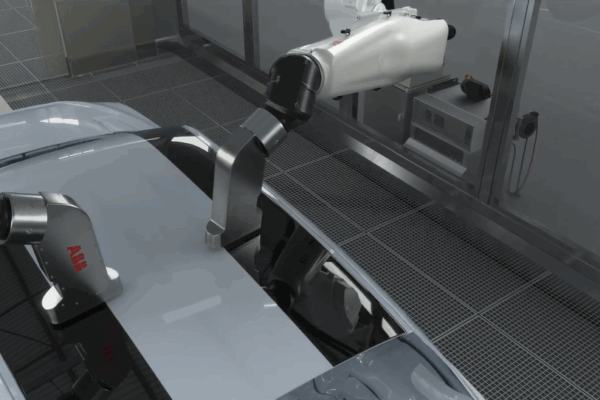

In recent years, Vietnam's automotive industry has witnessed remarkable progress, largely due to the adoption of modern technologies in automotive assembly systems. This advancement has not only improved product quality…

In the context of the automobile and motorbike market increasingly focusing on personalization, the demand for two-color paint and unique patterns is increasing. However, traditional painting technology still has many…

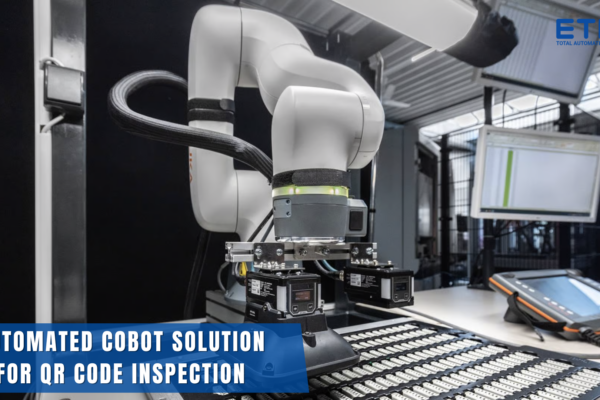

The system uses a collaborative robot (cobot) combined with two industrial cameras to automatically inspect Data Matrix codes laser-marked on plastic product surfaces. The cobot performs sequential movements to position,…