Palletizing robots are one of the industrial robot applications that offer many benefits and are highly appreciated in the manufacturing plant. They are in charge of loading and unloading goods, arranging smart logistics. So, what is a palletizing robot? The benefits brought in the production process for businesses, let’s find out right away in the article below.

A palletizing robot is a robot that automatically sorts and arranges goods and products on pallets, serving at the end of the production line.

Palletizing processes can be carried out through the use of manual labor, conventional systems, or by industrial robots. Conventional palletizing systems used to be the method of choice, but as the manufacturing process becomes more and more modernized, companies are turning to automation with robotic palletizing systems.

Automating the palletizing process with robots creates flexibility in production activities. As the production process is increasingly modernized, factories are gradually transforming themselves to automation systems to meet the changes and requirements of customers.

Modern palletizing robots can stack many other SKUs without much change compared to the requirements to meet the expectations of many different types of customers.

Palletizing robots adapt to a variety of pallets, including wooden and plastic pallets, with new forms of product packaging that are difficult to handle. The robot can lift and unload products of different shapes and sizes allowing.

Palletizing robots integrate robotic palletizing systems that improve the ergonomics of workers. The robot can do all the lifting and palletizing work with ease.

The task of lifting palletizing products can put a strain on the musculoskeletal system when repetitive and prolonged.

Automation eliminates the risk of workplace injuries and minimizes the cost of treatment caused by injuries. In short, the palletizing process will be more efficient when using palletizing robots at the same time, workers can also participate in doing better jobs.

All of the above benefits are cost-effective. Palletizing robots are much more cost-effective than other palletizing systems because they have flexible loading and unloading capabilities with a variety of pallets of different shapes, sizes, and materials.

Palletizing robots also have a long service life and continuous operation to meet various production requirements. At the same time, the robot can also increase ROI quickly and integrate a variety of grippers.

See more >>> Palletizing robot – Robotic Palletazing application

ETEK Automation Solutions Joint Stock Company provides palletizing robot solutions in accordance with the requirements of each business.

——————————————————-

FOR MORE INFORMATION, PLEASE CONTACT ETEK AUTOMATION SOLUTIONS JOINT STOCK COMPANY

Head office address 189 Phan Trong Tue- Thanh Liet- Thanh Tri- Ha Noi

Hotline: (+84) 965.800.166 Or leave information at Boxchat

Email: info@etek.com.vn

What is Sealing? Sealing is the process of creating a protective layer or barrier to prevent the intrusion or leakage of liquids, gases, dust, or other contaminants between surfaces or…

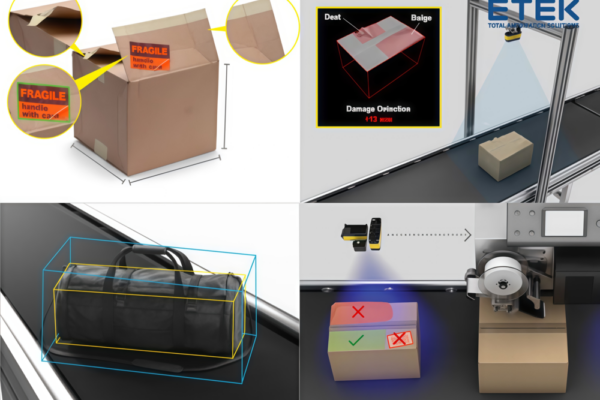

The 3D-A1000 dimensioning system is a compact industrial smart camera capable of capturing moving objects in both 2D and 3D. It is equipped with powerful vision tools that enable automation…

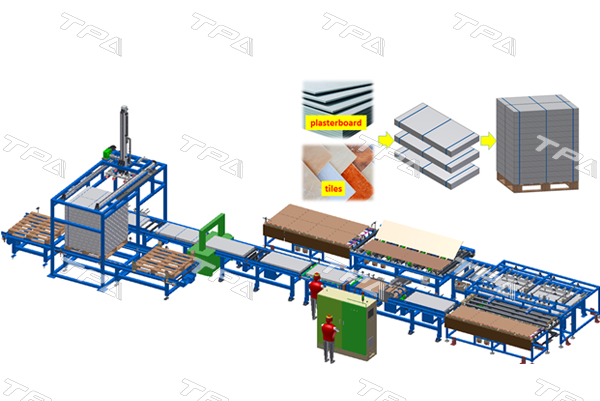

DESCRIPTION Application Packaging, pallerizing Professions CPG, F&B, Metal, Auto, Construction.. PRODUCTS Description Large & heavy products : tiles, plasterboard… Dimensions (max) (mm) 600 x 1200 x 100* Weight (max) (kg)…

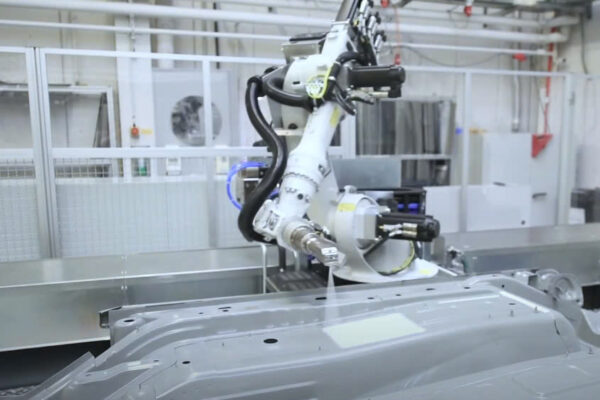

In recent years, Vietnam's automotive industry has witnessed remarkable progress, largely due to the adoption of modern technologies in automotive assembly systems. This advancement has not only improved product quality…