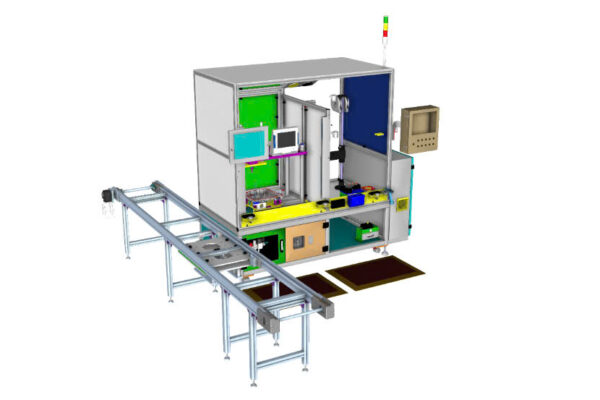

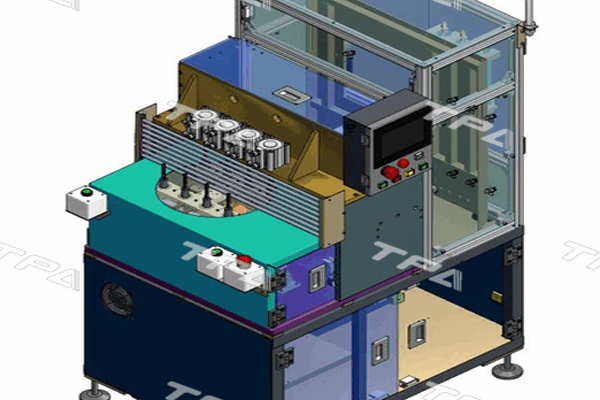

Our Metal Processing Solution offers cutting edge technology for cutting, shaping, and forming metal parts with the highest precision. This solution utilizes advanced machinery such as laser cutters, CNC machines, and forming machines to handle a wide variety of metalworking tasks, including cutting, bending, and shaping. Whether you are in the automotive, heavy equipment, or electronics industries, our metal processing solution ensures accuracy, durability, and efficiency in every process.

Designed to meet the specific needs of various industries, this solution offers both flexibility and reliability in metal fabrication. Furthermore, it helps companies produce high-quality components with minimal waste, ensuring efficiency and sustainability in the production process.

ETEK has experience integrating custom material handling, laser welding, ultrasonic welding, and heat staking solutions for our customers. You can fabricate, join, or assemble their metal parts quickly and efficiently.

Our metal processing solution is applied across several industries where high-precision metalwork is required:

In industrial production lines, every assembly step plays a vital role in ensuring the quality of the final product. One of the key steps is pin pressing, which helps secure…

A large Continuous inkjet printer is a specialized device designed to print large-sized products such as banners, posters, billboards, and other promotional materials. Capable of printing on various materials such…

What is Automated Glue Applicator? Glue application automation is the use of glue application robots, cobots (collaborative robots) and intelligent control systems to perform the glue application process on the product…

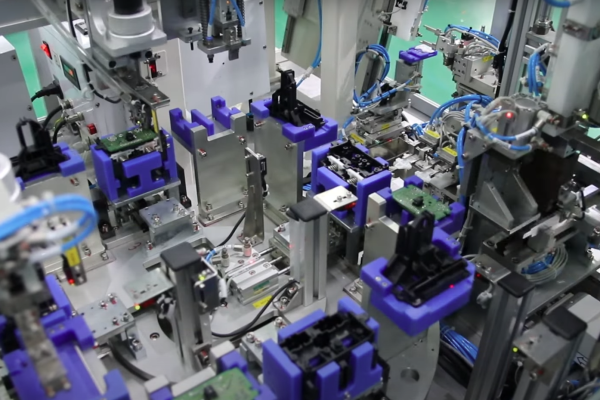

What is automation in the electrical and electronics industry? Automation in the electrical and electronics industry is essential in improving production efficiency, reducing labor costs, and ensuring safety in manufacturing…