In modern production processes, ensuring that cartons are securely, aesthetically, and efficiently sealed is a critical factor in improving product quality and optimizing packaging lines. The case sealer (carton sealing machine) is an exceptional automation solution that meets all end-of-line packaging needs, from speed and accuracy to aesthetics. So, what exactly is a case sealer and why has it become an indispensable device in various industries?

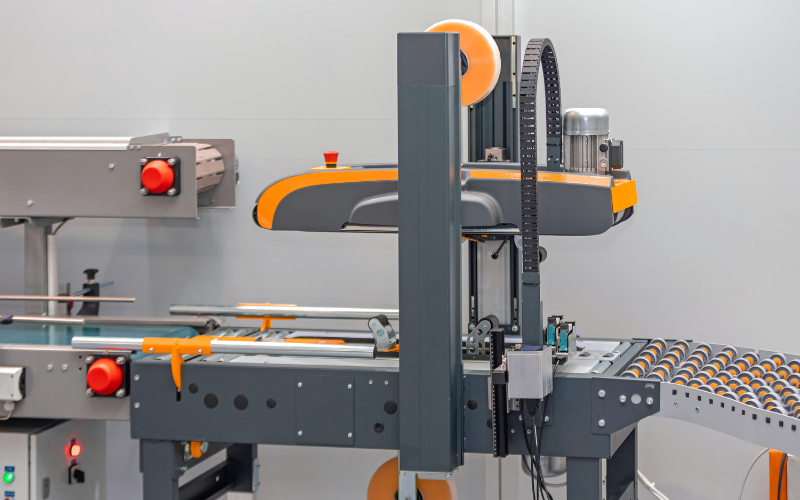

A case sealer is a specialized device designed to automatically seal cartons using adhesive tape or hot melt glue. This equipment ensures secure, uniform sealing while minimizing errors, enhancing aesthetics, and streamlining the end-of-line packaging process.

Case sealers are widely used in various industries due to their flexibility and high efficiency:

With its exceptional features, the case sealer is an indispensable solution for businesses aiming to optimize production processes and enhance product quality.

Contact ETEK now for detailed consultation on automation solutions tailored to your business needs!

In modern manufacturing, packaging automation optimizes processes, enhances productivity, and reduces costs. Automated packaging systems handle tasks like filling, sealing, labeling, and palletizing with high precision and speed, making them…

In modern production environments, accuracy and speed are key factors in determining efficiency. The automatic bottle feeding machine (Bottle Feeding) has emerged as an outstanding solution to automate the bottle…

The automatic bottle filling machine is an essential device in modern production lines, designed to automate the process of filling liquid products into packaging quickly and efficiently. With advanced technology,…

The case packer machine is a modern solution designed to optimized the automatic packaging process for bagged products. With its quick, precise and flexible operation, the machine not only increases…

What is Delta robot? Robot delta (Spider Robot) is a line of robots with a distinct design compared to other stationary industrial robots. The name delta comes from its inverted…

Are you seeking a quick, cost-effective, and professional packaging solution? The automatic wrapping machine is the perfect choice to protect goods, optimize costs, and enhance production efficiency for your business.…

In the context of industry 4.0, automating processes has become an inevitable trend for businesses. Among the prominent solutions, palletizer robots are considered advanced technology that helps optimize product packaging…