In modern manufacturing, repetitive tasks such as picking and transferring products between production stages not only consume time but also waste human resources. The High-Speed Pick and Place System emerges as an intelligent automation solution that optimizes production processes.

Equipped with sensors and machine vision, the system can quickly pick and place products, even on moving conveyor belts, helping businesses enhance production efficiency. How is this technology applied across industries? Let’s explore the benefits and real-world applications of high-speed pick-and-place systems in the article below!

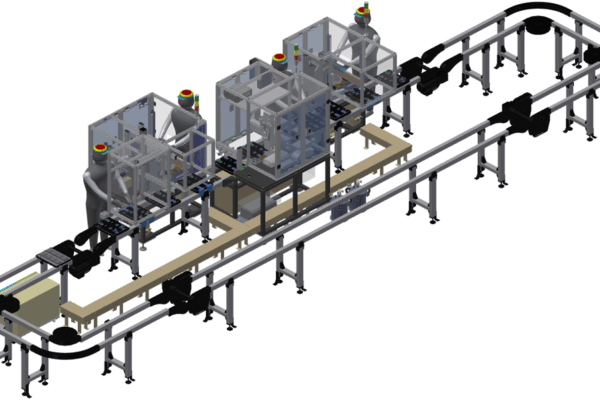

The High-Speed Pick and Place System is an advanced automation solution that utilizes robots or precision mechanical structures to pick, transfer, and position products from one location to another at high speed with absolute accuracy. This technology streamlines production workflows, minimizes errors, and boosts productivity.

In consumer goods manufacturing, high-speed pick-and-place systems enhance efficiency in packaging, assembly, and quality control processes. Key applications include:

With the ability to handle a variety of products such as candy, biscuits, chips, and noodles, this system significantly increases productivity for confectionery manufacturers:

In food processing, high-speed pick-and-place systems ensure food safety standards while improving production efficiency:

In automotive and motorcycle manufacturing, pick-and-place systems play a crucial role in:

With the rapid development of the electronics industry, high-speed pick-and-place systems have become an essential part of production lines:

The pharmaceutical sector demands high precision and quality assurance. High-speed pick-and-place systems help with:

High-speed pick-and-place systems offer outstanding advantages for businesses:

With these benefits, high-speed pick-and-place systems are the top choice for businesses aiming to boost production efficiency and upgrade their automation processes.

At ETEK, we provide cutting-edge high-speed pick-and-place solutions to help businesses enhance productivity and optimize manufacturing workflows.

Contact our experts today for detailed consultation!

Operated on the “goods-to-person” principle, the VLM increases productivity by delivering items directly to the operator.These systems feature a flexible modular design, allowing future adjustments to meet your business needs.…

In the context of the electronics industry increasingly requiring flexibility, speed and high quality, ETEK introduces a semi-automatic LCD screen assembly line solution , applying the advanced Collaborative Automation model -…

In today's rapidly evolving electronics industry, remote control devices are essential components across automotive and consumer electronics sectors. The demand for high-volume production with consistent quality requires sophisticated automation solutions.…

In today's competitive speaker and audio equipment manufacturing landscape, delivering consistent quality and maximizing productivity while controlling costs presents critical challenges for manufacturers worldwide. ETEK Automation delivers cutting-edge automated speaker…