In today’s competitive electrical and electronics manufacturing landscape, cooling fans are critical components powering computers, industrial equipment, and consumer electronics worldwide. Meeting demanding requirements for consistent quality, high-speed production, and cost-effective manufacturing requires cutting-edge automation technology. ETEK delivers state-of-the-art automated cooling fan assembly line solutions that seamlessly integrate advanced inspection systems, precision assembly robotics, automated fastening processes, and comprehensive quality control protocols to maximize production efficiency and product reliability.

Our advanced cooling fan assembly line serves diverse manufacturing sectors, producing high-quality cooling fans for computers and electronic devices, industrial cooling systems, and power supply equipment across consumer electronics and industrial electrical applications. The automated system efficiently manufactures various cooling fan types including axial fans, centrifugal fans, and specialized cooling solutions for desktop computers, servers, gaming systems, HVAC equipment, power inverters, and industrial machinery. This comprehensive capability makes our assembly line the ideal solution for electronics manufacturers, computer hardware companies, and industrial equipment producers seeking reliable, high-volume cooling fan production with consistent performance standards and rapid time-to-market delivery.

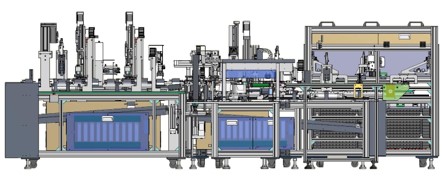

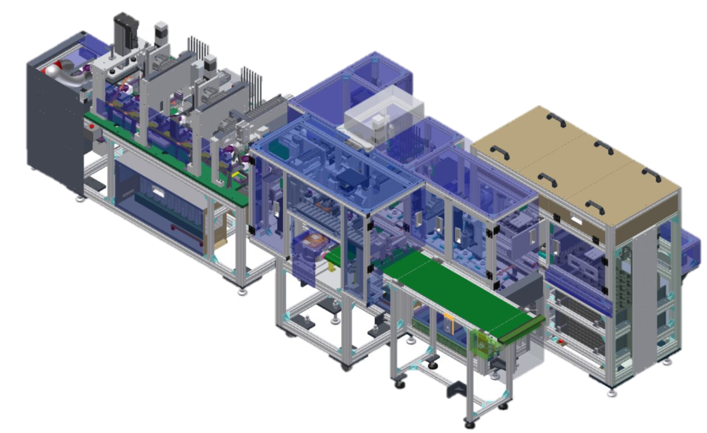

The assembly line integrates 4 main sequential operations in optimized linear configuration for maximum throughput and quality assurance:

1. Circuit and Bearing Inspection: Automated input component verification using precision measurement systems and electrical testing equipment to ensure motor specifications and bearing quality.

2. Washer and Bearing Installation: Robotic precision operations for rotation component fixation using force-controlled assembly systems with automated positioning and torque verification for enhanced lifespan.

3. Housing and Fan Blade Assembly: Automated accurate fitting processes using vision-guided robotics and precision alignment systems to prevent misalignment, vibration, and operational noise issues.

4. Final Quality Inspection: Comprehensive automated testing including noise level measurement, rotation speed verification, electrical connection validation, and performance parameter analysis with pass/fail classification.

ETEK Automation stands as the leading partner in electronics production automation, delivering comprehensive turnkey solutions from initial design consultation through implementation, ongoing maintenance, and future assembly line upgrades. Our cooling fan assembly systems incorporate the latest Industry 4.0 technologies, predictive maintenance capabilities, and scalable automation platforms designed to grow with your business needs.

Transform Your Cooling Fan Manufacturing Today

Experience the ETEK advantage with cutting-edge automation technology, expert engineering support, and proven results across hundreds of successful installations worldwide.

Refer to ETEK’s completed projects HERE

Contact ETEK Automation for Custom Solutions:

Address: 189 Phan Trong Tue Street, Thanh Liet Ward, Thanh Tri District, Hanoi, Vietnam

Hotline: 0965 800 166

Email: info@etek.com.vn

Website: https://etekautomation.com.vn

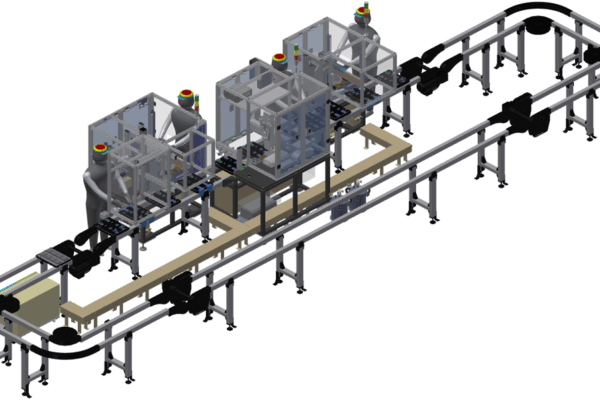

Our Stamping Solution provides an efficient, high-speed method for producing stamped components from metal and plastic materials. Using automated stamping machines, robots, sensors, vision systems, conveyors, etc., to meet the…

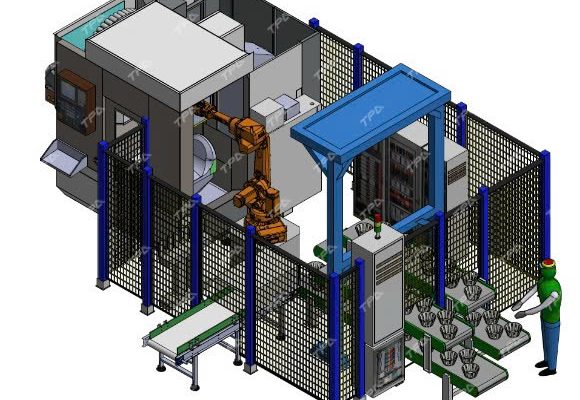

The Robotic Milling Solution utilizes industrial robots to perform high-precision milling and shaping operations with consistent accuracy and stable performance. The solution enables manufacturers to increase productivity, enhance design flexibility,…

How Automation Works in the Food and Drink Industry Automation in the food and drink industry involves the application of technology to various production stages. Automation in food processing demands…

In today's competitive speaker and audio equipment manufacturing landscape, delivering consistent quality and maximizing productivity while controlling costs presents critical challenges for manufacturers worldwide. ETEK Automation delivers cutting-edge automated speaker…