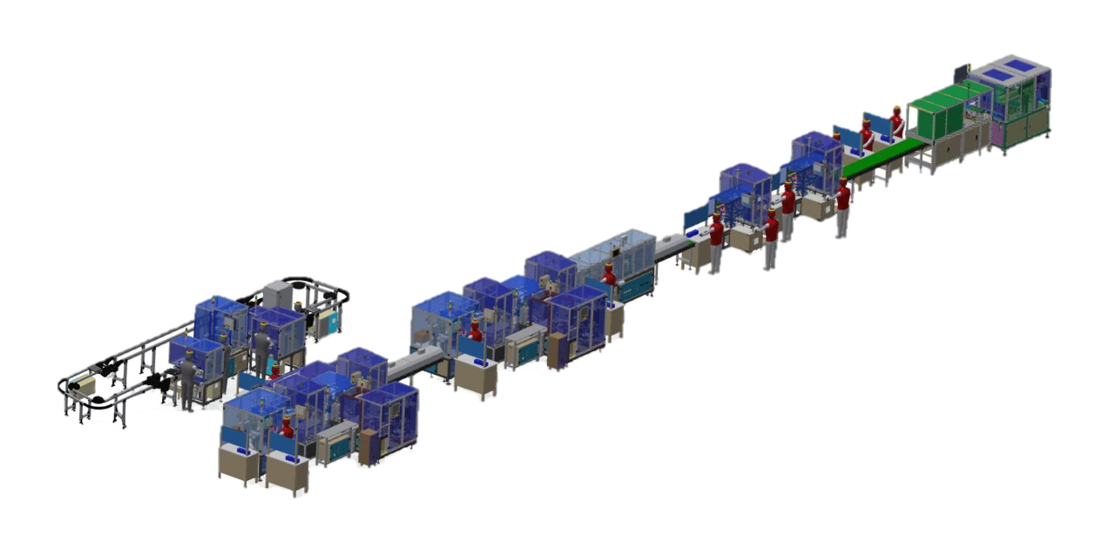

In today’s competitive speaker and audio equipment manufacturing landscape, delivering consistent quality and maximizing productivity while controlling costs presents critical challenges for manufacturers worldwide. ETEK Automation delivers cutting-edge automated speaker assembly line solutions that seamlessly integrate advanced robotic technology, precision adhesive dispensing systems, automated soldering equipment, and comprehensive inspection protocols. Our innovative automation solutions enable businesses to dramatically reduce production time, minimize labor costs, and achieve superior product accuracy and durability standards that exceed industry expectations.

Our advanced speaker assembly line serves diverse manufacturing sectors across the 3C industries including computing, telecommunications, and consumer electronics, as well as industrial electronics for audio equipment, smart speakers, and IoT devices. The automated system efficiently produces various speaker types including high-performance woofers, precision tweeters, Bluetooth speakers, automotive audio systems, and professional sound equipment for home entertainment, commercial audio installations, and automotive manufacturers. This comprehensive manufacturing capability makes our assembly line the optimal solution for audio equipment manufacturers, consumer electronics companies, and automotive suppliers seeking reliable, high-volume speaker production with exceptional acoustic performance, consistent quality standards, and rapid market deployment capabilities.

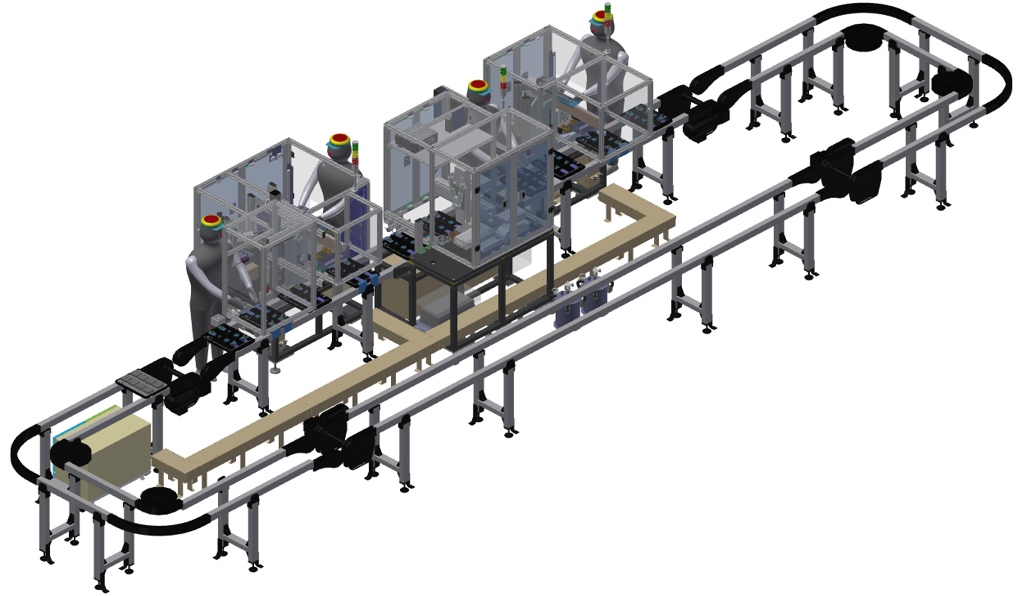

Our precision-engineered process features 13 sequential operations designed for optimal workflow efficiency and superior audio quality:

1. Yoke and Magnet Insertion: Automated installation of magnetic components and magnetic core into product frame using precision robotic positioning systems.

2. Yoke and Magnet Adhesive Application: Precise positioning fixation using automated dispensing equipment with controlled flow rates and pattern accuracy for optimal bonding.

3. Terminal Installation: Robotic mounting of signal connection terminals with torque-controlled fastening and electrical continuity verification for reliable connections.

4. Wire Winding: Automated voice coil winding using specialized precision equipment with tension control and layer uniformity for optimal performance.

5. Spider Attachment: Precision installation of center suspension components to support oscillation movement using automated alignment and bonding systems.

6. Adhesive Spraying: Uniform adhesive application using automated spray nozzles with pattern control and thickness monitoring for consistent coverage.

7. Diaphragm Attachment: Automated installation of speaker cone onto magnetic assembly using precision positioning systems with vibrating membrane alignment verification.

8. Heat Drying: Temperature-controlled thermal treatment for rapid adhesive curing and enhanced bonding strength using conveyor oven systems.

9. Soldering: Automated component lead soldering ensuring optimal electrical contact using precision soldering equipment with temperature and time control.

10. Center Cap Attachment: Robotic installation of center cap for enhanced audio stability using precision adhesive application and positioning systems.

11. Dust Cap Attachment: Automated installation of dust cap to protect voice coil from contaminants using precision bonding with alignment verification.

12. Foam Padding: Precision application of foam padding for improved acoustic sealing and vibration dampening using automated dispensing systems.

13. Quality Inspection: Comprehensive automated quality control system for performance verification and defect detection using advanced testing and measurement equipment.

ETEK AUTOMATION – Leading Partner in Audio Equipment Manufacturing Automation

Our speaker assembly solutions incorporate Industry 4.0 technologies, predictive maintenance capabilities, and scalable platforms designed to meet evolving market demands. We deliver comprehensive support from initial consultation through installation, training, and ongoing technical support.

Transform Your Speaker Manufacturing Operations Today

Experience superior automation technology with proven results across hundreds of successful audio equipment manufacturing installations worldwide.

Check out the entire simulation video here:

Refer to ETEK’s completed projects HERE

Contact ETEK for Custom Speaker Assembly Solutions:

Address: 189 Phan Trong Tue Street, Thanh Liet Ward, Thanh Tri District, Hanoi, Vietnam

Hotline: 0965 800 166

Email: info@etek.com.vn

Website: https://etekautomation.com.vn

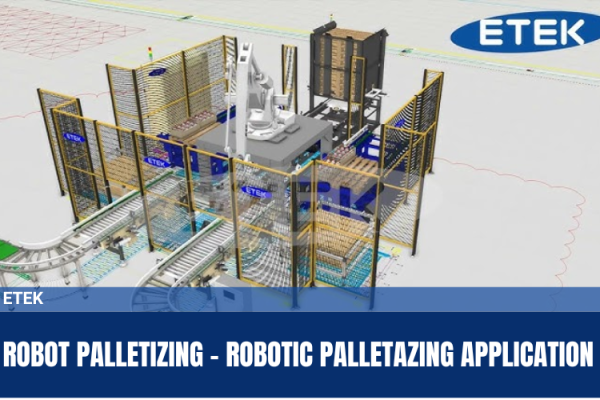

In industrial production, one of the stages prioritized for automation is the loading and unloading of go ods... From now on, businesses should turn automation solutions into their competitive advantage…

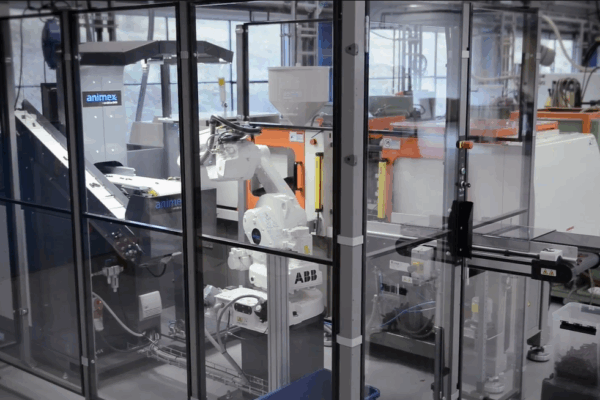

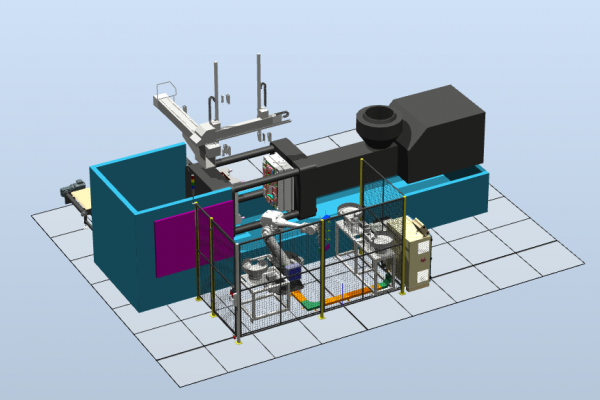

Are you looking for an efficient automation solution for your plastic molding station? ETEK provides comprehensive automated robot solutions, helping businesses improve productivity, reduce labor costs and ensure stable product…

The rapid growth of electric vehicles is driving increasing demand for battery safety components, particularly pressure relief valves for automotive applications. These valves play a critical role in relieving internal…

The casting industry is a manufacturing sector that creates products by pouring materials in a liquid state into molds to produce items with shapes identical to the mold. This process…