Operated on the “goods-to-person” principle, the VLM increases productivity by delivering items directly to the operator.

These systems feature a flexible modular design, allowing future adjustments to meet your business needs.

Save space and optimize room height

Create a convenient working environment

Ensure goods are stored safely

More storage capacity within a smaller footprint

Increased throughput

Improved inventory control

A flexible solution for small parts and light inventory

The Kardex Shuttle 250/500 is a versatile solution for storing and retrieving small-scale inventory. With a tray width of 4,050 mm, it can handle loads of up to 560 kg per tray. Its compact design allows it to adapt to various space requirements, providing maximum storage capacity in minimal floor space, with a maximum height of up to 30 meters. Moreover, the system can be easily modified to meet diverse requirements — for example, to store goods in temperature-controlled units or cleanroom environments.

Compact storage for medium loads

The Kardex Shuttle 700 handles trays with a width of 4,050 mm and loads of up to 725 kg per tray. With an equipment height of up to 20 meters, it offers large storage capacity. The Kardex Shuttle 700 is ideal for efficiently storing heavy materials, tools, components, or spare parts. It is extremely flexible, offering several options that can be easily integrated before or after installation. Units can be expanded, reduced, modified, or adjusted in various ways to meet changing needs such as business growth, new applications, or relocation.

Handles heavy loads up to 1,000 kg

With a tray width of 4,050 mm, the Kardex Shuttle 1000 manages loads up to 1,000 kg per tray. Meeting new load-bearing standards, it is the ideal product for storing medium to heavy parts. Using forklifts, Euro pallets and mesh boxes can be stacked and stored in specially designed trays. This saves space, allows faster item retrieval, and helps reduce costs while improving productivity and ergonomics. Factory-installed cranes can be used to move stored goods easily, minimizing time and operational costs.

| Model | Shuttle XP 250/500 | Shuttle XP 700 | Shuttle XP 1000 |

|---|---|---|---|

| Width | 1,580 – 4,380 mm | 1,580 – 4,380 mm | 1,580 – 4,380 mm |

| Depth | 2,312 – 3,074 mm | 2,363 – 3,125 mm | 2,363 – 4,343 mm |

| Height | 2,550 – 30,050 mm | 2,550 – 20,050 mm | 2,550 – 20,050 mm |

| Load Capacity | Up to 560 kg | Up to 725 kg | Up to 1,000 kg |

| Tray Pitch | 100 mm | 100 mm | 100 mm |

Water heaters are essential appliances in every modern household, requiring precise, safe, and consistent manufacturing processes. With extensive experience in production automation, ETEK provides automated water heater assembly line solutions…

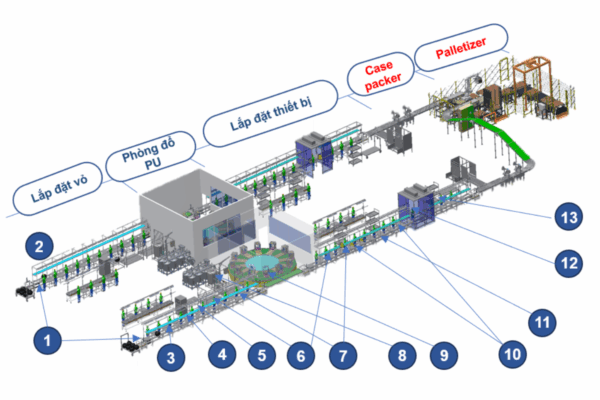

In modern manufacturing, packaging automation optimizes processes, enhances productivity, and reduces costs. Automated packaging systems handle tasks like filling, sealing, labeling, and palletizing with high precision and speed, making them…

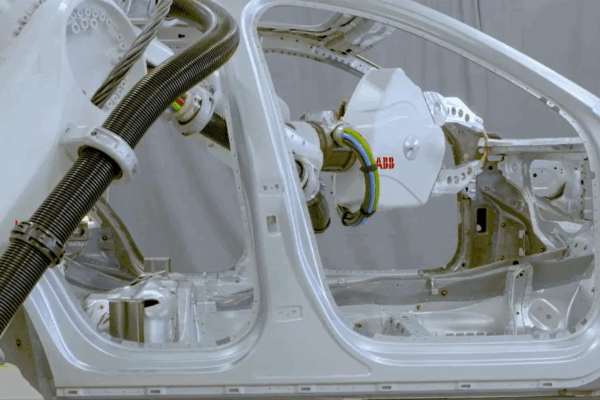

Spot Welding is one of the popular resistance welding methods , widely used in the manufacturing industry due to its efficiency and high automation capability. This is the ideal solution for connecting thin…

The high-density, high-speed, and flexible pallet storage system makes ETEK’s Automated Storage and Retrieval System (AS/RS) for pallets one of the most advanced automated warehousing solutions on the market. With…