Smart warehouses is a storage system that utilizes advanced technologies such as automation, the Internet of Things (IoT), Artificial Intelligence (AI), and Big Data to efficiently and accurately manage storage, inventory, and transportation processes. The goal of a smart warehouse is to optimize workflows, minimize errors and costs, and enhance operational performance and productivity. Depending on the scale and specific needs, businesses can choose suitable types of smart warehouses to improve operational efficiency and competitiveness in the market.

Smart warehouses are an essential part of the modern supply chain, helping enterprises optimize warehouse management, reduce operating costs, and increase productivity.

AS/RS System (Automated Storage and Retrieval System)

Features: Automated storage and retrieval system using robots or machinery to transport and store goods.

Advantages:

Applications: Ideal for businesses with large volumes of goods and requirements for fast and precise processing.

AGV System (Automated Guided Vehicles)

Features: Uses automated guided vehicles controlled by navigation systems to transport goods within the warehouse.

Advantages:

Applications: Suitable for warehouses with diverse goods and requiring flexible transport systems.

Pick-to-Light and Put-to-Light Systems

Features: Uses LED indicators to guide warehouse operators to the location of items to pick or place.

Advantages:

Applications: Suitable for small to medium-sized warehouses that require fast order processing.

Voice Picking System

Features: Uses voice recognition technology to guide warehouse staff in performing picking tasks.

Advantages:

Applications: Suitable for warehouses handling large quantities of goods with high accuracy requirements.

Warehouse Management System (WMS)

Features: Uses IoT sensors to monitor and manage goods in real time.

Advantages:

Applications: Suitable for all types of businesses, especially those with complex warehouse management needs.

RFID System (Radio Frequency Identification)

Features: Uses radio waves to automatically identify and track goods within the warehouse.

Advantages:

Applications: Suitable for warehouses requiring high levels of control and traceability.

Demand Forecasting System

Features: Uses AI to analyze data and forecast product demand.

Advantages:

Applications: Suitable for retail and manufacturing businesses requiring accurate demand forecasts.

Data Analysis and Optimization System

Features: Uses AI to analyze operational data and propose process optimization strategies.

Advantages:

Applications: Ideal for businesses aiming to boost operational efficiency and optimize warehouse management.

1. Optimized Space and Performance

2. Reduced Errors and Improved Accuracy

3. Cost Savings and Enhanced Safety

4. Easy Tracking and Management

With its position as a pioneering provider of automation solutions for industry and daily life in Vietnam, ETEK is collaborating with partners to develop smart and automated warehouse applications that make storage and transportation processes easier and more efficient for businesses.

Contact ETEK today to share your warehouse needs and receive the best support and solutions for your business.

In the era of smart manufacturing, flexible and safe automation is the key to improving productivity and reducing costs. ETEK introduces the autonomous vehicle combined with robotic arm (cobot) solution…

As manufacturing and logistics businesses increasingly focus on efficiency and accuracy, smart warehouse solutions are becoming a strategic choice to improve performance, save space and ensure safe operations. The Kardex…

A thermal transfer printer ( also known as a TTO - Thermal Transfer Overprinting machine) is a device that uses thermal transfer technology to print on packaging surfaces or other…

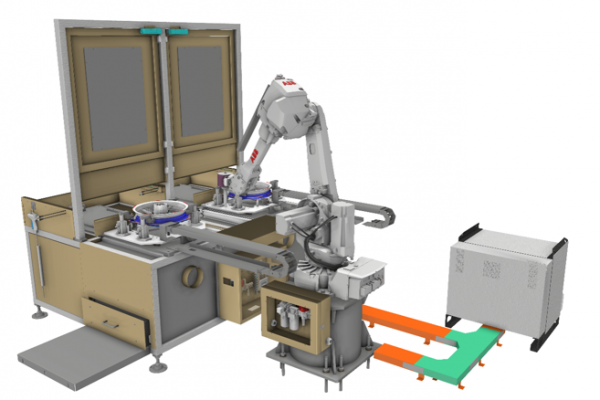

Our Surface Treatment Solution is designed to enhance the durability, appearance, and functionality of metal and plastic components by applying a range of protective coatings and finishes. This solution automates…