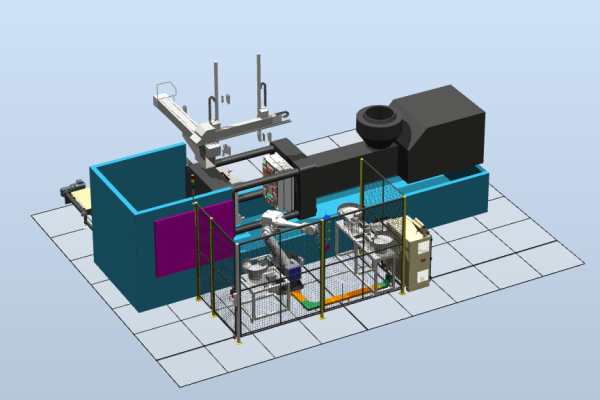

The plastic parts painting line supplied by ETEK has been successfully commissioned and is operating stably at the factory, meeting high requirements for surface quality and production stability. This is a dedicated painting solution for automotive plastic parts with complex geometries, where high aesthetics and durability are essential.

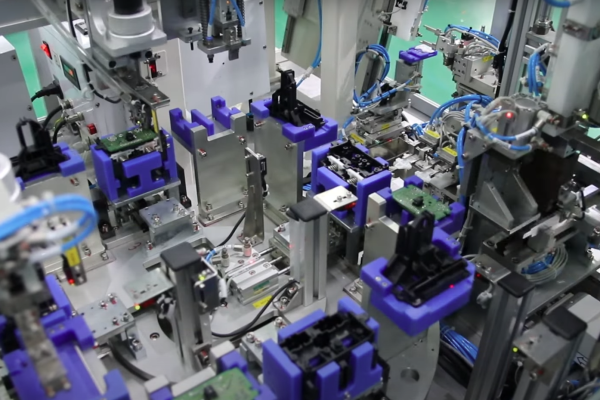

The system is designed as a closed-loop production line, integrating all processes from surface treatment, painting and curing to quality inspection. This ensures consistent paint quality and continuous operation, while helping manufacturers optimize investment costs and improve production productivity.

The following specifications reflect the line’s operational capability, production efficiency, and factory management integration in compliance with Industry 4.0 standards:

Capacity: 20 JPH

OEE: 90–95%

Factory management system integration: MES compliant with Industry 4.0 standards, including track & trace, ERP integration, and production management/monitoring.

ETEK’s system integrates all stages from surface preparation to final inspection. The process is scientifically designed to ensure stable and consistent paint quality:

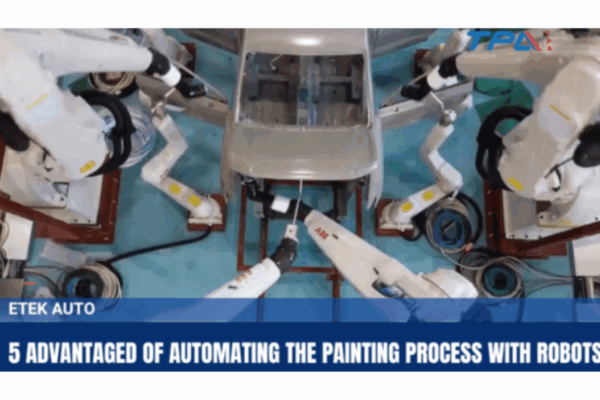

Investing in an automated painting line is not only a machinery upgrade but also a strategic enhancement of competitiveness, delivering tangible benefits:

Consistent and stable paint surface quality meeting high aesthetic requirements

Improved operational efficiency

Enhanced production control through MES integration

Suitable for various product types and factory scales, with easy expansion and upgrading

ETEK’s plastic parts painting line is widely applied across multiple industries:

Automotive & motorcycle industry: front/rear bumpers, body trims, front grilles, mirror housings, interior trims, dashboards, door panels, exterior decorative parts.

Electrical & electronics industry: electronic housings, control panel enclosures, power supply casings, switch and socket housings, protective frames and covers, engineering plastic enclosures.

Plastic manufacturing requiring surface finishing: colored plastic parts, glossy/matte painted components, decorative plastic housings, brand-identified plastic parts, high-aesthetic plastic products.

Contact ETEK for more detailed consultation

Let ETEK partner with you from assessment – design – manufacturing – installation – technology transfer.

Address: 189 Phan Trong Tue Street, Thanh Liet Ward, Thanh Tri District, Hanoi, Vietnam

Hotline: 0965800166

Email: info@etek.com.vn

Website: https://etekautomation.com.vn

What is automation in the electrical and electronics industry? Automation in the electrical and electronics industry is essential in improving production efficiency, reducing labor costs, and ensuring safety in manufacturing…

Integrating the Color Pick System into picking operations enhances workforce flexibility and enables businesses to handle sudden increases in order demand. The Kardex Color Pick System is a simple and…

What is automation in the consumer goods industry? In the context of fierce competition, automation is not only a trend but also a key solution for businesses to enhance their…

[embed]https://www.youtube.com/watch?v=-Vy6z_l6GcQ[/embed] Application of ABB Robot for automatic car painting Many businesses are hesitant to start considering the application of automation to the production line due to the large initial investment…