Palletizing robots and pallet-stacking robots are becoming increasingly important in manufacturing plants, effectively fulfilling the final task of automated line for stacking goods onto various types of pallets. The application of palletizing robots, particularly in industries such as manufacturing, food, and electronics, helps replace manual labor and significantly improves cost efficiency.

We always see the advantages and benefits that pallet stacking robots bring in production activities, however, to suit businesses, it is still necessary to focus on some shortcomings such as Palletizing robots require a skilled, specialized workforce to operate, deploy and perform tasks

Input costs are high compared to small and medium-sized enterprises, the number of order requirements is limited, so to invest and palletizing robots, it is necessary to study the cost as well as the size of the business to have the best plan.

ETEK Automation Solutions Joint Stock Company provides palletizing robots and palletizing robots in accordance with the requirements and feasibility for businesses and factories, and at the same time, there is always the best solution to minimize the risks that palletizing robots bring.

Video about Palletizing robots – Robotic Palletazing Application

——————————————————————————————————————

FOR MORE INFORMATION, PLEASE CONTACT ETEK AUTOMATION SOLUTIONS JOINT STOCK COMPANY

Head office address 189 Phan Trong Tue- Thanh Liet- Thanh Tri- Hanoi

Hotline: (+84) 965.800.166 Or leave information at Boxchat

Email: info@etek.com.vn

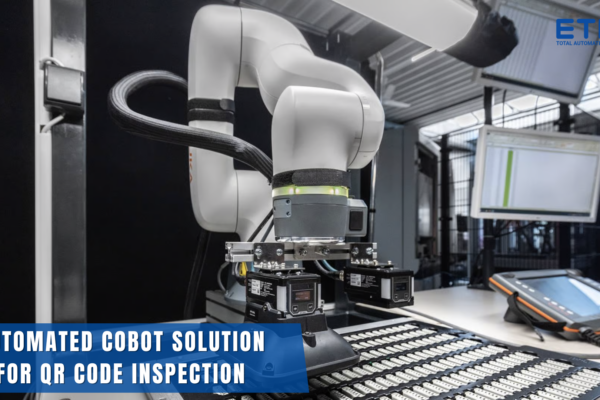

The system uses a collaborative robot (cobot) combined with two industrial cameras to automatically inspect Data Matrix codes laser-marked on plastic product surfaces. The cobot performs sequential movements to position,…

In the era of smart manufacturing, flexible and safe automation is the key to improving productivity and reducing costs. ETEK introduces the autonomous vehicle combined with robotic arm (cobot) solution…

The application of automated laser welding combined with 6-axis robots is becoming a mainstream trend in modern manufacturing plants. This technology provides optimal solutions for precision welding requirements on many different types of materials.…

What is automation in the intralogistics industry? Intralogistics refers to all logistics activities within the confines of a warehouse or factory, encompassing the design, implementation, management, monitoring, and optimization of…