The automotive industry demands high-volume tire manufacturing solutions that deliver exceptional speed, consistency, and reliability. ETEK Automation provides comprehensive tire assembly line systems that integrate advanced automation technology to meet the demanding requirements of modern tire production facilities.

Our automotive tire assembly solutions are designed to support a wide range of vehicle types, including passenger cars, commercial trucks, buses, industrial vehicles, and specialty automotive applications. These systems are ideally suited for use in the automotive and transportation sectors, particularly within vehicle manufacturing plants and tire production facilities, where speed, precision, and reliability are essential.

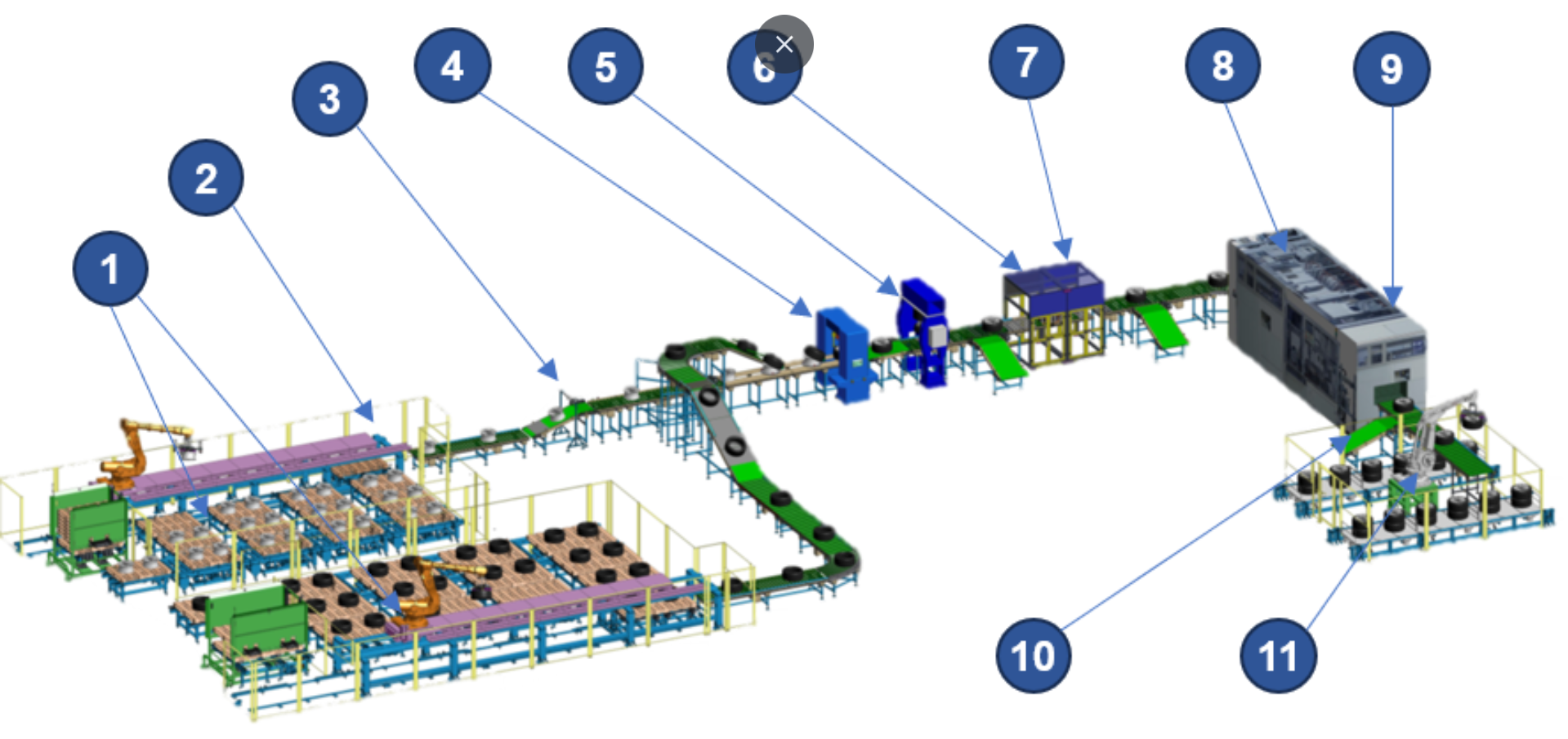

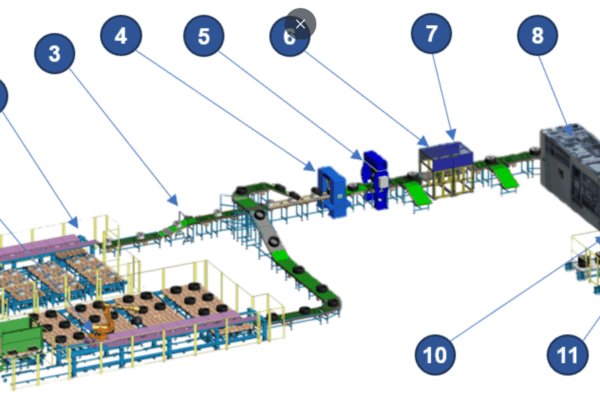

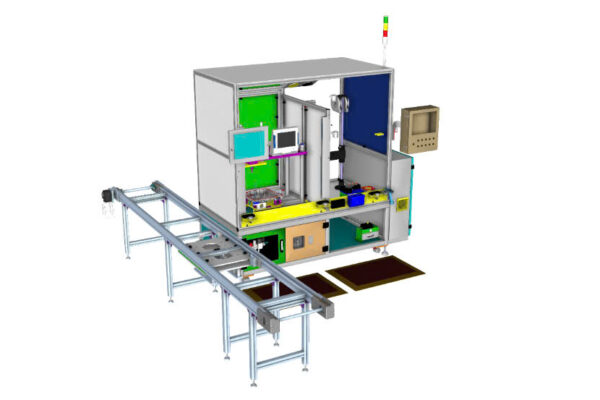

Our cutting-edge assembly line is engineered for maximum throughput, precision, and consistent quality. The fully automated 11-step process integrates intelligent control systems, high-speed robotics, and real-time data monitoring to deliver unmatched performance:

Our manufacturing system delivers fast, precise, and reliable output with up to 200 units per hour and sub-18 second cycle times. Advanced robotics ensure accurate assembly, while multi-stage testing— including balance checks—guarantees quality. Fully automated from loading to unloading, the process minimizes manual handling. Built-in inspection and rejection systems ensure only top-quality products reach packaging.

ETEK Automation delivers high-performance tire manufacturing systems with advanced barcode tracking, precision mounting technology, and comprehensive quality control. Our solutions integrate automated inflation systems, balance testing equipment, and intelligent sorting capabilities to ensure efficient, reliable tire production that meets automotive industry standards.

Refer to ETEK’s completed projects HERE

Transform your tire manufacturing capabilities with ETEK’s industrial-grade automation solutions. Our expert team provides complete support from design consultation through implementation and maintenance.

Contact ETEK Automation Today:

Address: 189 Phan Trong Tue Street, Thanh Liet Ward, Thanh Tri District, Hanoi, Vietnam

Phone: 0965800166

Email: info@etek.com.vn

Website: https://etekautomation.com.vn

The automotive industry demands high-volume tire manufacturing solutions that deliver exceptional speed, consistency, and reliability. ETEK Automation provides comprehensive tire assembly line systems that integrate advanced automation technology to meet…

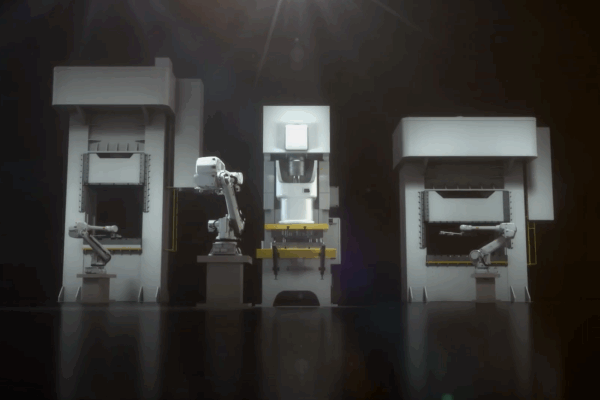

In industrial production lines, every assembly step plays a vital role in ensuring the quality of the final product. One of the key steps is pin pressing, which helps secure…

1. The Automation Trend in the Automotive Industry The automotive industries is entering the digital era, where automation plays a crucial role in enhancing efficiency, reducing costs, and improving product…

Are you looking for a press area automation solution? The stamping station automation solution deployed by ETEK will be the ideal choice for manufacturing enterprises that want to increase productivity -…