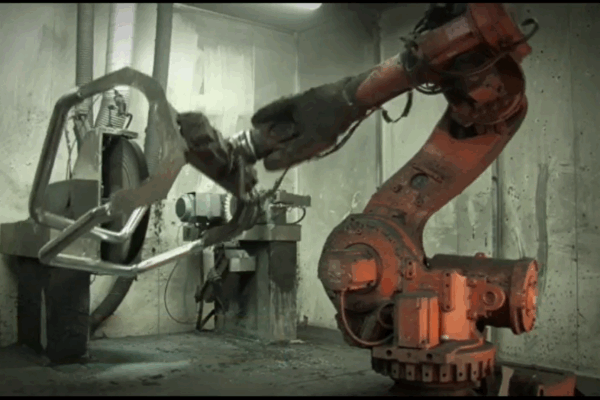

To maximize the flexibility of ABB’s robotic welding cells, the automotive parts manufacturing plant quickly installed 27 FlexArc robots to respond faster to end customer needs while maintaining cost efficiency.

The customer installed 27 ABB FlexArcs to serve the company’s production activities

Manufacturing of catalytic converters for automobiles

The customer wants to quickly increase the productivity of their factory and is looking for an automated welding solution that they can easily program to enhance production flexibility at the factory.

After preliminary calculations and detailed planning, 27 Robot FlexArc units were installed at the automotive parts manufacturing plant. ABB’s standard solution meets the customer’s needs, providing the necessary flexibility and allowing the plant to quickly scale production up or down to maximize operational efficiency.

From a single product manufacturer to a global supplier of automotive exhaust products. In just 27 years, the catalytic converter manufacturer has expanded its portfolio, expanded into new geographic regions, and is now a leading supplier to some of the world’s largest automotive companies.

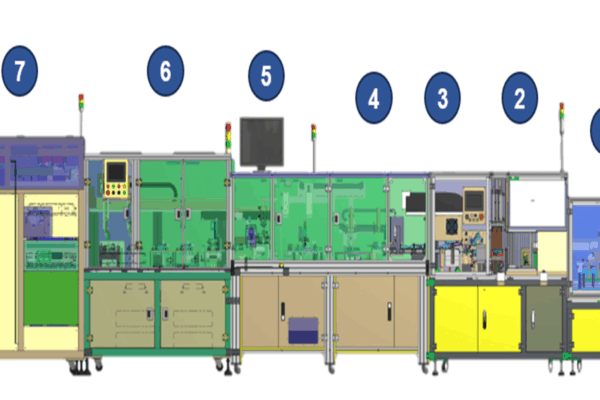

As the business booms globally, this world’s largest automotive parts supplier faces a rapidly growing need for its production capacity. After some research, the company decided it needed an automated welding solution that could be easily programmed to enhance production flexibility at the plant by allowing the company to quickly scale production up or down to maximize operational efficiency. Available in a range of standardized packages, the FlexArc robotic welding cell incorporates everything needed for welding applications, including a welding robot with superior motion control software, positioners, and related welding equipment, all built on a common platform.

The ABB Robotics Application Center created a welding cell that businesses can easily replicate to increase capacity. Unlike other welding solutions that require building from scratch, operators can seamlessly load programs from previous work cells onto the new ABB FlexArc and use the same fixture design. Replicating the system across any factory globally, the robot reduces the time and cost associated with modifying production lines to meet changing customer demands.

Flexibility defines the core of FlexArc design. The automotive industry often faces uncertain demand, as end customers rarely require guaranteed quantities. A solution is essential to address this variability.

FlexArc ABB is an ideal solution because a soldering cell can be easily adapted to other products. Depending on the purpose of the end customer, the factory can set up a welding process and use more or less FlexArc depending on the needs. The flexibility of the welding cell allows the company to use the same jig to fabricate products for different customers with minimal design changes.

FlexArc cells are helping to improve both productivity and worker safety. On one side of the positioner, the operator loads the parts that need to be welded on a fixture. The robot IRB2600 located on the other side then welds the parts together. When the welding process is complete, the machine will hand over the finished parts to the operator, who will unload them and replace them with new parts. The robot’s welding accuracy and speed are enhanced by ABB’s TrueMove and QuickMove motion platforms that optimize weld seams, reduce rework and reduce production cycle times.

FlexArc’s integrated design enhances safety during welding. The metal sheets cover the electrical equipment, and the conductors sit inside special steel frames. This design also shields the cell from sparks generated during the soldering process. ABB supplies all FlexArcs with a fume hood, which operators can connect to the fume extraction system. This protects people and keeps the work chamber free of debris.

ABB enables every FlexArc to simulate on RobotStudio, its offline robot programming software. Using ABB’s dedicated PowerPac welding software add-on, the factory can quickly create complex robotic paths for its FlexArcs. With RobotStudio, the company tests every aspect of the welding process virtually before setting up the system, without affecting actual production. The simulation identifies potential problems, such as collisions between welding torches and jigs, allowing the team to fix them as needed.

RobotStudio provides the auto parts factory with another way to maximize the investment in FlexArc welding umbrellas. By simulating a new project, the factory can estimate production costs and cycle times. It can also calculate the operating manpower or the number of robots needed. By connecting to RobotStudio with engineering programs like AutoCAD, ABB can import jig designs. This allows the factory to test the entire welding process setup before starting production. Robert Mrozik, an expert from ABB, said this approach enhances efficiency.

Every new design of the jig and any new parts produced can be uploaded to Robot Studio for customers to check if any problems still exist. We can test accessibility for welding, torch positioners, and jig constructions. We can easily check the collision between the welding torch and any part of the jig. Overall, this solution reduces the cost of producing welding jigs, which means savings for the factory’s customers.

An important advantage of the standard FlexArc cell design is that employees do not need intensive training before starting machine operation. The intuitive FlexPendant graphical user interface provides an overview of the cell’s status. It also allows operators to communicate effectively with all the cell’s functions and access information about its performance.

Smart warehouses is a storage system that utilizes advanced technologies such as automation, the Internet of Things (IoT), Artificial Intelligence (AI), and Big Data to efficiently and accurately manage storage,…

In the context of the automobile industry increasingly moving towards automation and high quality , the application of car bumper polishing robots has become an inevitable trend to help businesses improve productivity, optimize costs…

The cobot-based automatic machine tending solution feeds raw parts and finished products into CNC machines, replacing repetitive, high-precision tasks while ensuring safe collaboration with human workers. What is Cobot Machine…

The 3C electronics industry requires ultra-fast manufacturing solutions that deliver exceptional speed, precision, and reliability. ETEK Automation provides comprehensive printer power supply assembly line systems that integrate cutting-edge automation technology…