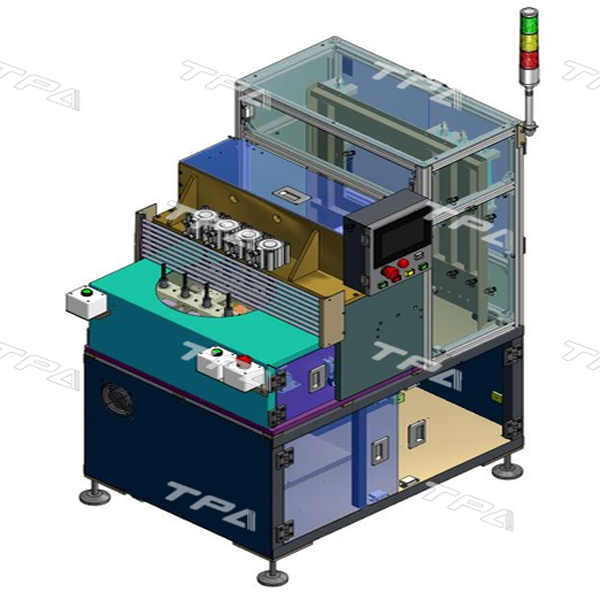

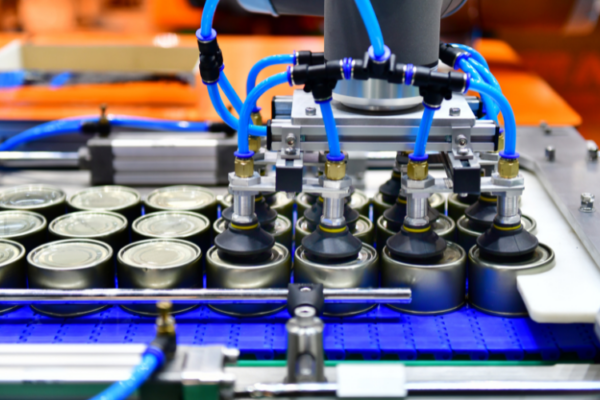

Glue application automation is the use of glue application robots, cobots (collaborative robots) and intelligent control systems to perform the glue application process on the product surface. The entire glue application process is automated with high precision, fast speed, and tight glue control, helping to increase efficiency and quality in mass production.

Not only simply replacing workers, the automatic glue application system is also flexibly programmed for each specific product, ensuring uniformity, aesthetics and safety much higher than manual methods.

When applying glue-applying robots to the production line, businesses will receive a series of benefits such as:

Precise glue application position, tight control of glue profile and flow, contributing to minimizing product defects and improving consistency in the production process.

Automatic glue application solution replaces manual labor, allowing the system to operate continuously at high intensity, thereby significantly shortening production time.

The intelligent control system helps to accurately calculate the amount of glue needed for each product, minimizing loss, glue overflow, and dirt.

Workers are no longer in direct contact with chemicals, contributing to reducing accidents, occupational diseases and adverse health impacts .

Modern glue-applying Robots /Cobots can be integrated into existing automation systems, supporting connection to production lines, inspection systems, control systems, etc., very flexibly and optimizing the entire production process.

Automatic glue application technology can be customized to suit many different fields, such as:

ETEK is proud to be a pioneer in the field of providing and integrating automatic glue application solutions , with nearly 20 years of experience in the automation industry . We provide comprehensive solutions from A–Z:

Don’t let manual gluing slow down your business growth. Let ETEK accompany you in the transformation to modern manufacturing!

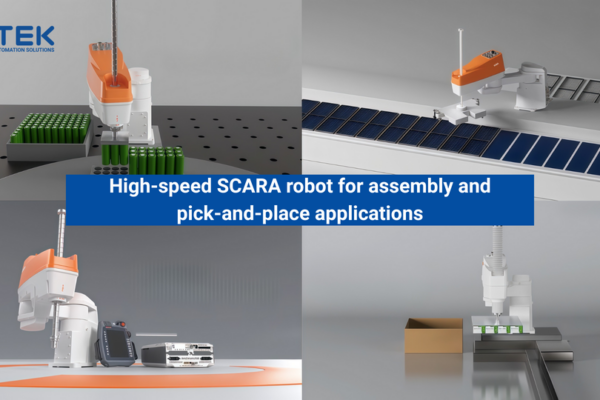

OVERVIEW The KR SCARA robot is a high-performance industrial robot, distinguished by its powerful operation and exceptional speed in modern production lines. For applications such as small-part assembly, material handling,…

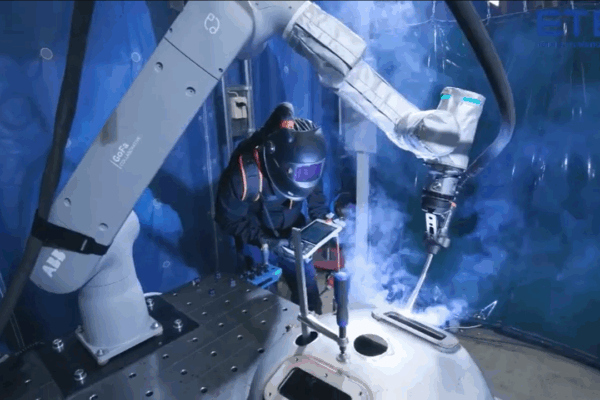

In the industrial kitchen equipment manufacturing industry, the quality of the weld not only determines the durability and safety but also directly affects the aesthetics of the product. In particular,…

These robotic arms allow for disassembly or even complete replacement, revolutionizing how humans interact with robots and artificial intelligence (AI). The company's website states: "Half a century after the introduction…

Rising labor costs, inconsistent production efficiency, and errors in processing and packaging are becoming major challenges for instant food manufacturers. Given these difficulties, finding optimal solutions to enhance production efficiency…