In the context of fierce competition, automation is not only a trend but also a key solution for businesses to enhance their competitiveness. Automation in the plastics industry is the solution that uses robots, machinery, and modern equipment to replace humans in production processes. The application of automation technologies aims to improve equipment and enhance operational capacity. Machinery systems in plastic factories need to operate efficiently and stably for long periods to optimize performance, improve product quality, and save costs.

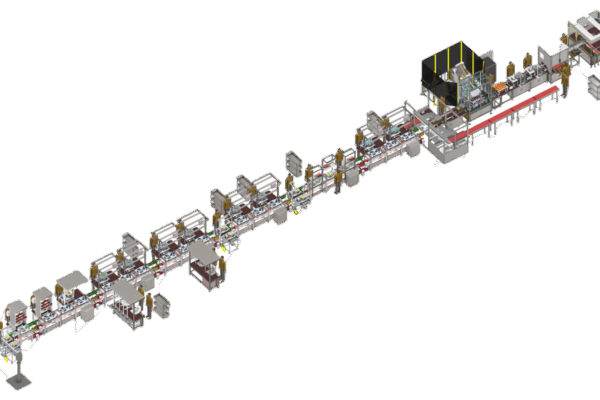

Automation systems in the plastics industry include robot applications, plastic injection molding systems, plastic blow molding systems, and more. Robots have long been considered invaluable assistants in factories and production plants, automating tasks to increase productivity and improve product quality. Hazardous chemicals, dust, and pollution from the plastic molding industry are the main reasons for labor shortages.

Nowadays, with the continuous development of modern technology, integrating automation solutions into production processes has helped businesses overcome these challenges. Understanding the difficulties companies face, we have researched and developed integrated automation solutions that combine machinery, robots, sensors, and vision systems to optimize production.

We have experience implementing the following systems:

ETEK has extensive experience implementing projects with major clients such as Vinfast, etc.

The application of automation in the plastics industry is an inevitable trend in the modern world. Automation in the plastics sector brings numerous benefits, such as:

In the context of the electronics industry increasingly requiring flexibility, speed and high quality, ETEK introduces a semi-automatic LCD screen assembly line solution , applying the advanced Collaborative Automation model -…

The exponential growth of the electric motorcycle and electric vehicle industry demands increasingly sophisticated standards for high-volume productivity, precision manufacturing, and stringent quality control across all battery production processes. At…

In the context of the mobile phone manufacturing industry increasingly requiring high speed and precision, the application of automation technology to the product quality inspection line is becoming an inevitable…

[embed]https://www.youtube.com/watch?v=-Vy6z_l6GcQ[/embed] Application of ABB Robot for automatic car painting Many businesses are hesitant to start considering the application of automation to the production line due to the large initial investment…