Our Painting Solution provides an automated system for applying consistent and high-quality coatings to various products, ensuring a smooth and uniform finish every time. This solution is ideal for industries such as automotive, electronics, and consumer goods, where precision in surface finishing is critical. The system incorporates robotic spray arms, automated paint mixing systems, and real-time quality monitoring, allowing for a controlled and efficient painting process.

Our painting solution reduces material waste, minimizes errors, and increases productivity. It meets the needs of high-volume production environments, delivering both speed and accuracy.

Our painting solution adapts to various industries that require high-quality surface finishes.

With nearly five years of experience, ETEK is one of the leading providers of coating lines for industrial applications on plastic, metal, or wood items. We handle every step from design, manufacturing to installation and operation, ensuring that your company has a safe and efficient process from the initial concept to the final handover.

The ETEK coating lines are designed to operate efficiently and reliably for many years and are customized by our in-house technical team for each project. Our ability to tailor solutions for each project allows us to provide everything from manual lines to fully automated systems.

ETEK’s industrial wet and powder coating lines are offered as a complete package, including all necessary processing areas:

In the era of modern industry constantly developing, automation technology has been reshaping the way manufacturing industries operate, helping businesses improve efficiency and reduce costs. In particular, in the automobile…

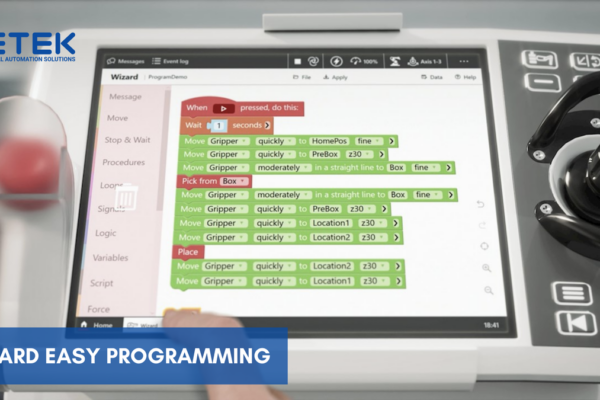

In the era of automation, operating robots is no longer reserved for highly experienced programming experts. With Wizard Easy Programming robot programming software, users can set up and operate robots…

What is automation in the consumer goods industry? The food and beverage industry is a sector that produces items such as candy, bottled beverages, etc. In modern society, this industry…

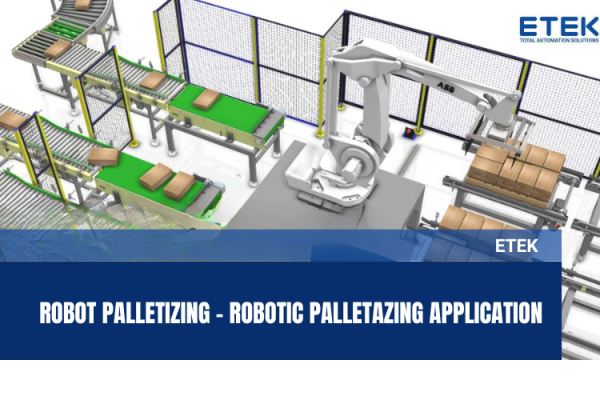

Palletizing robots are one of the industrial robot applications that offer many benefits and are highly appreciated in the manufacturing plant. They are in charge of loading and unloading goods,…