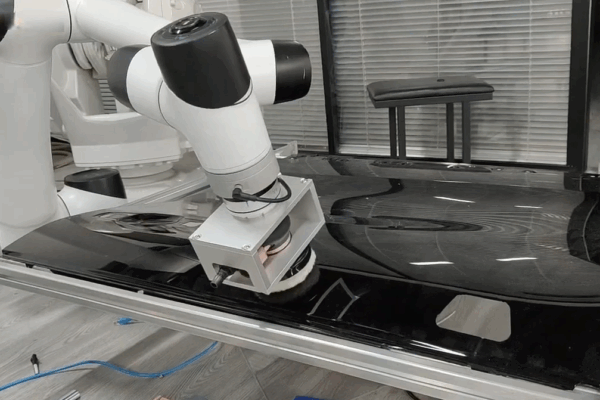

The robot solution for attaching components (Component insert robot solution) automatically to the 450T plastic molding mold helps automate the process of attaching components to the plastic mold of the molding machine, thereby improving manufacturing productivity, ensuring product output quality as well as reducing production costs.

Currently, factories producing plastic molding products are mainly using manual labor to attach products to plastic molding machine molds, which will cause some NG errors for products such as: mounting the wrong product, installing the wrong position of the product, installing the product not in accordance with the product requirements, etc. reducing the quality of output products and affecting the production schedule.

The current implementation steps include:

ETEK received a request from a customer about a robot that attaches automatic components to plastic molds as follows:

Model/type of insert product:

Customer requirements given to ETEK

– Insert time is 20s

– Working principle: 450T-1 casting station

– Outstanding features of the 450T automatic nut insert robot station

3D Operation Video Robot ABB Insert Nut Casting Station 450T

Actual Operation Video of ABB Robot Insert Nut Foundry Station 450T

Our advantages:

With more than 18 years of experience in the field of automation, ETEK is ready to offer the smartest solutions in providing robotic solutions that attach automatic components to 450T plastic molds to help increase productivity and bring high efficiency to your business.

——————————————————-

FOR MORE INFORMATION, PLEASE CONTACT ETEK AUTOMATION SOLUTIONS JOINT STOCK COMPANY

Head office address 189 Phan Trong Tue- Thanh Liet- Thanh Tri- Ha Noi

Hotline: (+84) 965.800.166

Or leave information at Boxchat

Website: etekautomation.com.vn

In the automotive industry, polishing plays a key role in ensuring that the product surface meets perfect standards before entering the next stages such as painting, assembly or shipping. Robotic polishing…

Coding & Marking Solutions are integral technologies in modern manufacturing, ensuring product traceability, quality assurance, and compliance with industry standards. These solutions involve the application of marks, codes, or labels—such…

In the automotive manufacturing industry, the quality of the paint layer not only determines the aesthetic appeal but also directly affects the durability of the product. The application of painting…

Modern laser engraving machines have become indispensable tools in various manufacturing and processing industries due to their ability to cut, engrave, and mark with exceptional precision and speed. This technology…