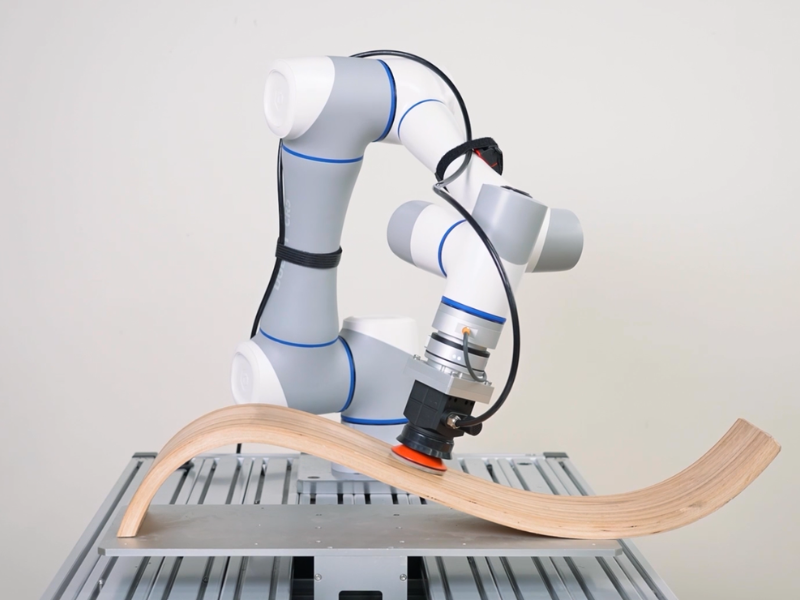

Over the years, traditional industrial robot system have played a vital role in automating polishing and finishing processes. However, as the demand for flexibility and cost optimization continue to grow, Cobot have emerge as a new direction for modern manufacturing. Keeping pace with this trend, ETEK introduces an advanced Cobot-based polishing and finishing, delivering outstanding efficiency for today’s manufacturing enterprises.

In general, the configuration of Cobot polishing system is similar to traditional industrial Robot, but it is enhanced with intelligent sensors and control mechanisms to ensure flexibility and safe collaboration with human. A typical polishing Cobot system includes:

– Robot Arms: Equipped advanced technology that enables automatic force adjustment, ensuring stable and uniform polishing. Integrate force sensors and position sensors allow the robot to recognize surface conditions and automatically fine-tune contact force and angle to achieve the highest level of precision.

– Central Controller: Processes data and controls motion with easy programming and operation.

– Polishing Tool Assembly: Includes a rotary motor and abrasive discs, suitable for a wide range of materials.

– Fixed Fixture & Dust Extraction System: Securely holds the workpiece and reduces dust, maintaining a clean and safe working environment

– At the start of operation, the Cobot is pre-programmed with the movement trajectory and the required force for each polishing stage. During operation:

+ Force sensors continuously collect feedback from the workpiece surface.

+ Based on this data, the system automatically adjusts pressure, speed, and tool direction.

+ This enables consistent contact force, preventing surface scratches and uneven polishing.

– With extensive real-world deployment experience, ETEK delivers a state-of-the-art Cobot polishing system that significantly improves productivity, stability, and operational safety.

– The advanced force-sensing system allows automatic posture and force adjustment according to surface conditions, ensuring stable, precise, and uniform polishing.

– The system features simple installation and rapid deployment, without requiring precise fixed positioning of the workpiece as in traditional systems.

– It is especially effective for polishing complex or moving surfaces, achieving accuracy and efficiency that are difficult to accomplish with manual labor.

– The system operates continuously with greater consistency than human workers, helping enterprises enhance productivity while significantly reducing operational and labor costs.

– The automated metal polishing solution supports a wide range of materials and flexibly meets the needs of multiple industries:

+ Electrical & Electronics: Polishing metal housings and components.

+ Automotive & Motorcycle: Finishing frames, logos, hoods, bumpers, and metal parts.

+ Metal Processing & Fabrication: Improving surface smoothness and aesthetic quality.

+ Consumer Goods Manufacturing: Polishing kitchenware and household appliances.

+ Furniture & Decoration: Surface finishing for wood, decorative metals, and artistic components.

With extensive experience in deploying automation solutions, ETEK provides a comprehensive automated metal polishing solution that helps enterprises enhance productivity and manufacturing quality.

Contact ETEK today for detailed consultation and to experience the most advanced Cobot polishing technology tailored to your production line.

In modern production environments, accuracy and speed are key factors in determining efficiency. The automatic bottle feeding machine (Bottle Feeding) has emerged as an outstanding solution to automate the bottle…

Palletizing is the process of loading products onto pallets on demand. In the final stage of the packaging line, the robot performs the task of bagging, the robot loads the…

Are you seeking a quick, cost-effective, and professional packaging solution? The automatic wrapping machine is the perfect choice to protect goods, optimize costs, and enhance production efficiency for your business.…

The cobot-based automatic machine tending solution feeds raw parts and finished products into CNC machines, replacing repetitive, high-precision tasks while ensuring safe collaboration with human workers. What is Cobot Machine…