The food and beverage industry is a sector that produces items such as candy, bottled beverages, etc. In modern society, this industry increasingly demands a wide variety of products while ensuring quality. To meet the continuous changes in the market, companies need to apply automation to their production processes to enhance productivity, adapt quickly, and respond in a timely manner to market demands.

Automation in the food and beverage sector involves the application of modern technology solutions, integrating robots, sensors, vision systems, etc., to replace human labor in many production stages, such as packaging automation, automated transportation, labeling, filling, inspection, and smart warehouses.

With the continuous development of technology and the application of AI in production, most production processes can now be automated. The integration of robotic solutions, palletizers, ARM/AGV for material handling, and control systems ensures smooth operation of the automation system.

We have extensive experience implementing projects for major clients such as Unilever, Th True Milk, Acecook, and many other consumer goods and beverage companies. Our automation solutions include:

The application of automation in the food and beverage industry brings many benefits such as:

Improved working conditions: In the production process, heavy and strenuous tasks that frequently expose workers to unhealthy environments can be replaced by machines. This enhances the health and morale of employees, creating a safer working environment.

Solution: A 3 in – 1 out palletizer system, combining vertical conveyors and overhead conveyors to merge the outputs of three production lines into one palletizer system.

What is Automated Glue Applicator? Glue application automation is the use of glue application robots, cobots (collaborative robots) and intelligent control systems to perform the glue application process on the product…

Smart warehouses is a storage system that utilizes advanced technologies such as automation, the Internet of Things (IoT), Artificial Intelligence (AI), and Big Data to efficiently and accurately manage storage,…

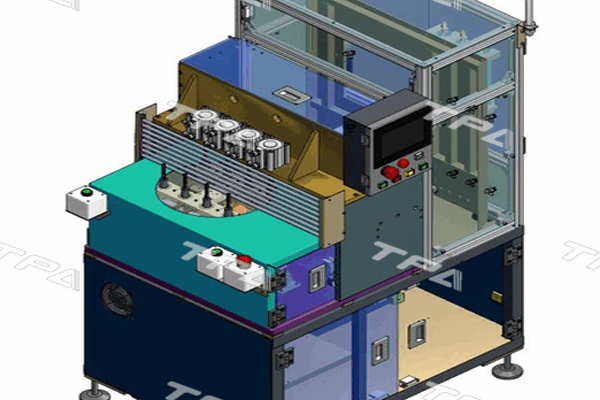

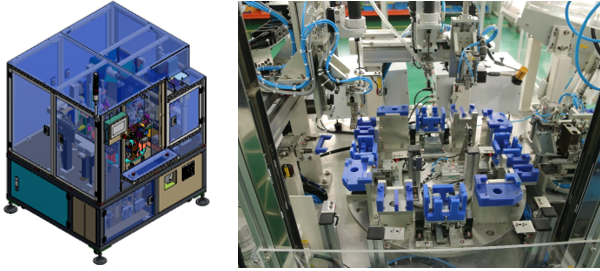

What is Screwiing Automation? In the past, before automation technologies were developed, screwing was primarily done manually using simple tools that relied on human labor, such as screwdrivers, handheld screw…

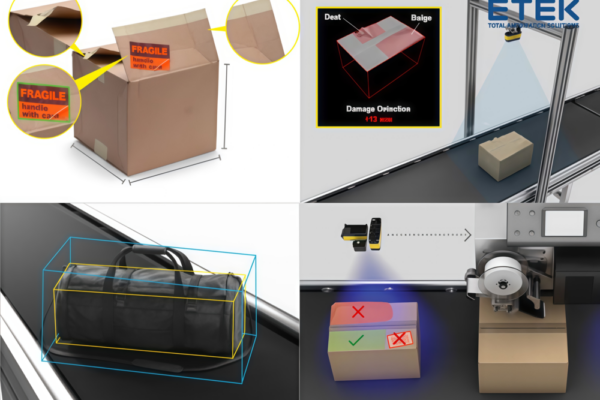

The 3D-A1000 dimensioning system is a compact industrial smart camera capable of capturing moving objects in both 2D and 3D. It is equipped with powerful vision tools that enable automation…