In the context of the strong explosion of Industry 4.0, the metal casting industry – one of the fundamental industries – is constantly innovating to keep up with the trend. In particular, the application of robot technology to automate the casting process is considered one of the breakthroughs, bringing great efficiency in both productivity and quality.

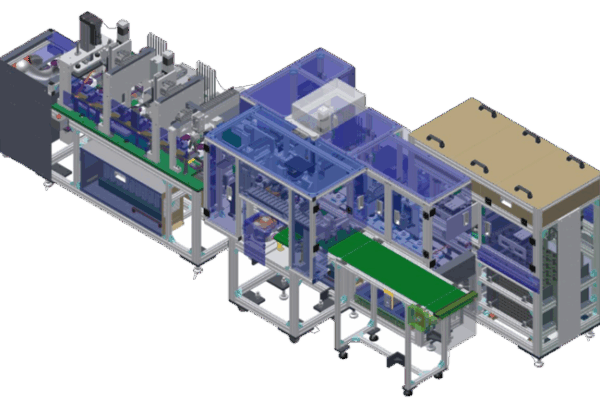

Metal casting is a production process that requires high precision and is affected by many environmental factors such as high temperature, dust, and chemicals. These conditions not only cause difficulties for workers but also pose many potential risks to labor safety. Deploying an automated robot system helps replace humans in dangerous stages and improve the stability of the entire chain.

Integrating robots into metal casting lines not only helps businesses solve productivity problems but also opens up many sustainable values in the long term:

Robotic automation is not only an immediate solution, but also the foundation for digital transformation in the foundry industry. The combination of robots, artificial intelligence (AI), MES and Big Data will create a smart production line, where every stage is connected and continuously optimized.

With obvious benefits in productivity, quality and cost, robotic metal casting process automation has become the top choice of many modern industrial enterprises. This is not only a strategic step to adapt to market fluctuations, but also a long-term solution to help businesses be more stable on the path of sustainable development and international integration.

Contact ETEK for detailed advice.

The Robotic Milling Solution utilizes industrial robots to perform high-precision milling and shaping operations with consistent accuracy and stable performance. The solution enables manufacturers to increase productivity, enhance design flexibility,…

In a medical equipment warehouse, accuracy, hygiene, and processing speed are not just goals—they are vital. A single picking error can disrupt the entire supply chain and directly affect the…

https://www.youtube.com/watch?v=CueLwlbNOeQ Challenges in Traditional Warehouse Management In today’s increasingly competitive environment, manufacturing and logistics companies are facing numerous challenges in warehouse management: Warehouses are full but still short of space:…

In today's competitive electrical and electronics manufacturing landscape, cooling fans are critical components powering computers, industrial equipment, and consumer electronics worldwide. Meeting demanding requirements for consistent quality, high-speed production, and…