The pharmaceutical and chemical industry plays a very important role in our lives. It produces everyday consumer goods such as medications, dietary supplements, cosmetics, and cleaning products. However, automation in this industry faces significant challenges duffed to adhere to strict processes and ensure quality.

Today, modern technology and artificial intelligence (AI) address many automation challenges faced by this sector. Many stages of the production process have been automated, including extraction/filling, sorting, packaging, and warehousing, … replacing human labor.

Our strength lies in developing automation solutions for pharmaceutical and chemical production lines. Our innovative solutions ensure smooth operations and minimize system downtime. We focus on integrating robots, sensors, conveyors, and PLC, IoT programming to fulfill customer tasks. We have extensive experience in building systems such as:

We have had the opportunity to collaborate with major clients such as Unilever, Orion, URC, etc. Our solutions have enhanced production capacity and have been scaled across multiple customer factories.

The application of automation in pharmaceutical and chemical production processes brings the following advantages:

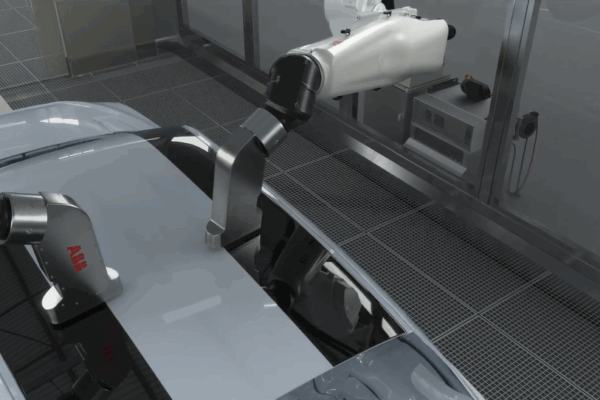

In the context of the automobile and motorbike market increasingly focusing on personalization, the demand for two-color paint and unique patterns is increasing. However, traditional painting technology still has many…

An automatic labeling machine is a device designed to print and apply labels directly onto products and packaging as they move along a conveyor. These machines integrate bot printing and…

What is automation in the automotive industry? Automotive automation refers to the use of advanced technology in the manufacturing process or products to transfer part or all of the tasks…

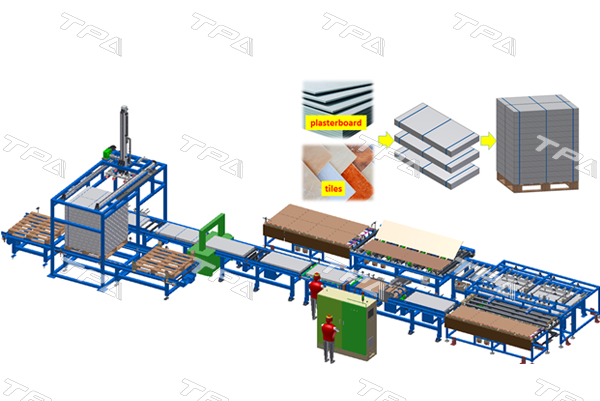

DESCRIPTION Application Packaging, pallerizing Professions CPG, F&B, Metal, Auto, Construction.. PRODUCTS Description Large & heavy products : tiles, plasterboard… Dimensions (max) (mm) 600 x 1200 x 100* Weight (max) (kg)…