Application of ABB Robot for automatic car painting

Many businesses are hesitant to start considering the application of automation to the production line due to the large initial investment cost, but in the end, the benefits it brings far exceed expectations. Specifically for the paint automation process, the 5 most prominent advantages are: reducing costs, improving quality, reducing waste, increasing flexibility and reducing labor costs.

The biggest challenge for industrial companies is to improve operational efficiency and productivity, reduce costs, and mitigate risks. Automating manual task completion processes allows your business to remain profitable in today’s demanding market.

Automation and robotics are less expensive than you think, and prices are falling every year. The initial investment cost may seem too expensive, but automating the production process will increase output and reduce costs. It will continue to provide benefits for many years to come, helping businesses save money in the long run.

To remain competitive, manufacturers need to improve product quality as best as possible, especially for the paint sector. The robot can ensure that the parameters of the spray gun and the spray movement are exactly the same every time, which helps to increase the product quality. Even the most skilled painters can’t guarantee that the paint is uniform and accurate for each part. Better consistency means less material is wasted.

Automating the robotic spraying process ensures near-perfect accuracy, thereby significantly reducing material consumption. According to research, compared to manual methods, paint automation can reduce the waste of materials and waste by up to 30%, save fuel and effectively protect the environment.

Robots can be easily reprogrammed to complete new tasks. Why invest in a new device when robots can make adjustments quickly? This flexibility not only saves time during the change, but also significantly saves costs. Automation provides the flexibility to change materials and colors more frequently, allowing you to simplify your production planning.

The robot provides 24/7 non-stop operation. In fact, the robot can replace the work of three employees with the ability to work three shifts, eight hours a day. As a result, businesses have saved labor costs and management costs. But the workforce itself benefits from robots in a number of ways. Robots perform repetitive (not to mention boring) tasks on their behalf, helping to minimize on-the-spot injuries and job dissatisfaction among workers. Not only that, but robots also replace employees, the company’s most valuable asset, doing dangerous jobs, allowing them to focus on skilled labor jobs that require decision-making and judgment.

——————————————————–

FOR MORE INFORMATION, PLEASE CONTACT ETEK AUTOMATION SOLUTIONS JOINT STOCK COMPANY

Head office address 189 Phan Trong Tue- Thanh Liet- Thanh Tri- Ha Noi

Hotline: (+84) 965.800.166 Or leave information at Boxchat

Email: info@etek.com.vn

Are you looking for an automated confectionery packaging solution where pick-and-place robots operate with precision, box sealing systems work efficiently and the entire process runs smoothly with a high level…

In modern manufacturing, optimizing processes and increasing production speed have become essential requirements. The application of automation technology in packaging helps businesses reduce reliance on manual labor, improve accuracy, and…

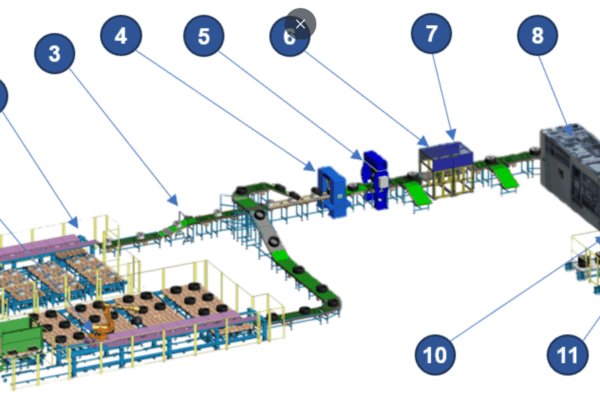

The automotive industry demands high-volume tire manufacturing solutions that deliver exceptional speed, consistency, and reliability. ETEK Automation provides comprehensive tire assembly line systems that integrate advanced automation technology to meet…

In the context of increasingly fierce competition, optimizing warehouse operations is a key factor to help businesses improve efficiency, reduce costs and serve customers faster. One of the advanced technology…