In the era of Industry 4.0, Intralogistics automation has become a key factor for businesses to optimize operational processes, reduce costs and improve productivity. Modern solutions such as smart warehouses, AGV/AMR robots and automatic conveyors are leading the trend, bringing precision, flexibility and outstanding efficiency to warehouse and production management systems.

With the ability to seamlessly integrate with management systems such as WMS and ERP, automated intralogistics solutions not only help businesses optimize storage space and minimize errors, but also increase transportation speed , meeting production and distribution needs in the digital age.

1. AGV/AMR Robot

One of the technological advances that businesses are favoring recently is the two types of autonomous robots AGV and AMR .

AGV (Automated Guided Vehicle) is a type of automatic guided robot that uses modern navigation technology (magnetic, QRcode, SLAM) that is pre-programmed , without requiring human intervention.

AMR (Autonomous Mobile Robot) is a type of autonomous mobile robot that can self-perceive its surroundings and self-plan its movements without the need for fixed guide lines like AGV.

Benefit:

Read more: the most popular types of AGV/AMR autonomous vehicles today

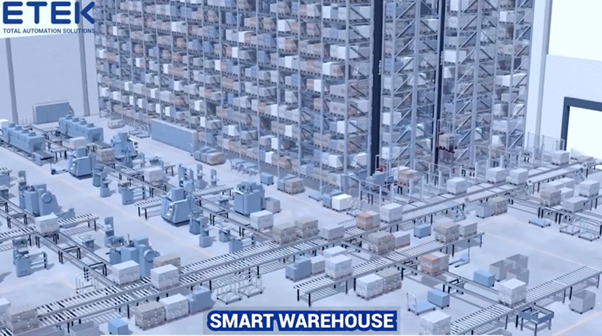

2. Smart Warehouse

Smart warehouse is an advanced logistics system that applies IoT technology , artificial intelligence (AI) , robots and automation to optimize warehouse management and operations. From receiving, storing to shipping, every process is digitized, controlled by smart sensors and warehouse management software (WMS), helping to minimize errors, increase processing speed and improve efficiency.

Benefit:

Read more: Smart warehouse solutions

3. Automatic Conveyor

The continuous transport system is integrated with smart technology, allowing automatic transport of goods from one location to another . The flexible design helps to minimize manual operations, increasing speed and accuracy in the internal transport process.

Benefit:

Read more: Conveyor systems and applications of conveyors in industry

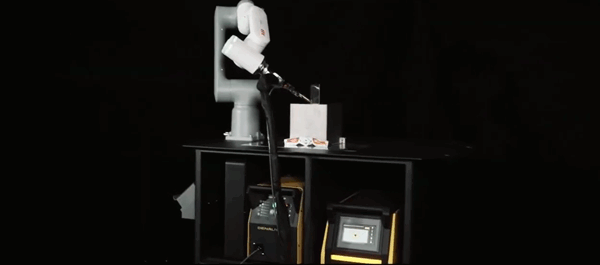

4. Mark & Read System

Technology automatically prints and compares real data to control information , avoiding errors when bringing products to market. With this system, products will be printed with information about the manufacturer, expiry date as well as QR code, then classify the products: products that meet standards and products with incorrect information.

Benefit:

Watch a video about the Mark & Read system:

5. Pick-to-Light

Smart picking guidance solution using LED system and display screen. Helps warehouse staff determine the location and quantity of goods to be picked quickly and accurately. The system significantly reduces the time spent searching for goods and speeds up the process of performing operations by staff.

Benefit:

Read more: Pick to Light smart product search solution in automobile assembly plant

Watch the video summarizing Intralogistics automation solutions:

Contact ETEK for detailed advice

With nearly 20 years of experience in the field of production automation and system integration, ETEK provides a comprehensive solution ecosystem for the electronics industry, from consulting, design, integration to training and lifetime maintenance of equipment.

Are you looking for the optimal solution for your electronics production line? Let ETEK accompany you on your journey to build a smart – efficient – modern factory.

Smart warehouses is a storage system that utilizes advanced technologies such as automation, the Internet of Things (IoT), Artificial Intelligence (AI), and Big Data to efficiently and accurately manage storage,…

Welding robots are widely used in manufacturing plants of various large and small scales. With a large investment capital, high requirements but bringing practical benefits to production activities and the…

The application of automated laser welding combined with 6-axis robots is becoming a mainstream trend in modern manufacturing plants. This technology provides optimal solutions for precision welding requirements on many different types of materials.…

In the era of Industry 4.0, the electronics manufacturing sector is facing increasing pressure in terms of speed, precision, and operational efficiency. To meet these demands, Autonomous Mobile Robots (AMRs)…