The rapid growth of electric vehicles is driving increasing demand for battery safety components, particularly pressure relief valves for automotive applications. These valves play a critical role in relieving internal pressure when batteries overheat, helping to prevent thermal runaway, fires, and explosions while significantly enhancing vehicle safety.

To meet stringent requirements for safety, precision, and high production volumes, manufacturers are increasingly shifting toward fully automated robotic assembly solutions.

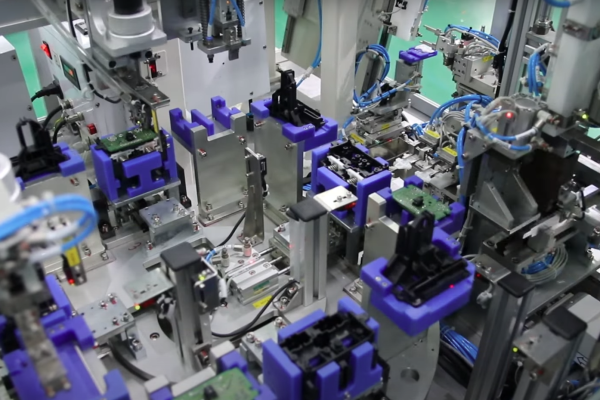

The solution is implemented as a closed, fully automated assembly cell, integrating six industrial robots operating simultaneously and precisely coordinated across every process step—from component feeding and assembly to comprehensive quality inspection.

The entire system is optimized to achieve a production capacity of up to 2 million pressure relief valves per year, effectively supporting mass production in the electric vehicle battery and automotive industries.

The process is fully standardized and automated, including:

This closed-loop process ensures that every pressure relief valve meets safety standards before leaving the production line.

In the context of the electronics industry increasingly requiring flexibility, speed and high quality, ETEK introduces a semi-automatic LCD screen assembly line solution , applying the advanced Collaborative Automation model -…

In recent years, Vietnam's automotive industry has witnessed remarkable progress, largely due to the adoption of modern technologies in automotive assembly systems. This advancement has not only improved product quality…

What is automation in the electrical and electronics industry? Automation in the electrical and electronics industry is essential in improving production efficiency, reducing labor costs, and ensuring safety in manufacturing…

Smart warehouses is a storage system that utilizes advanced technologies such as automation, the Internet of Things (IoT), Artificial Intelligence (AI), and Big Data to efficiently and accurately manage storage,…