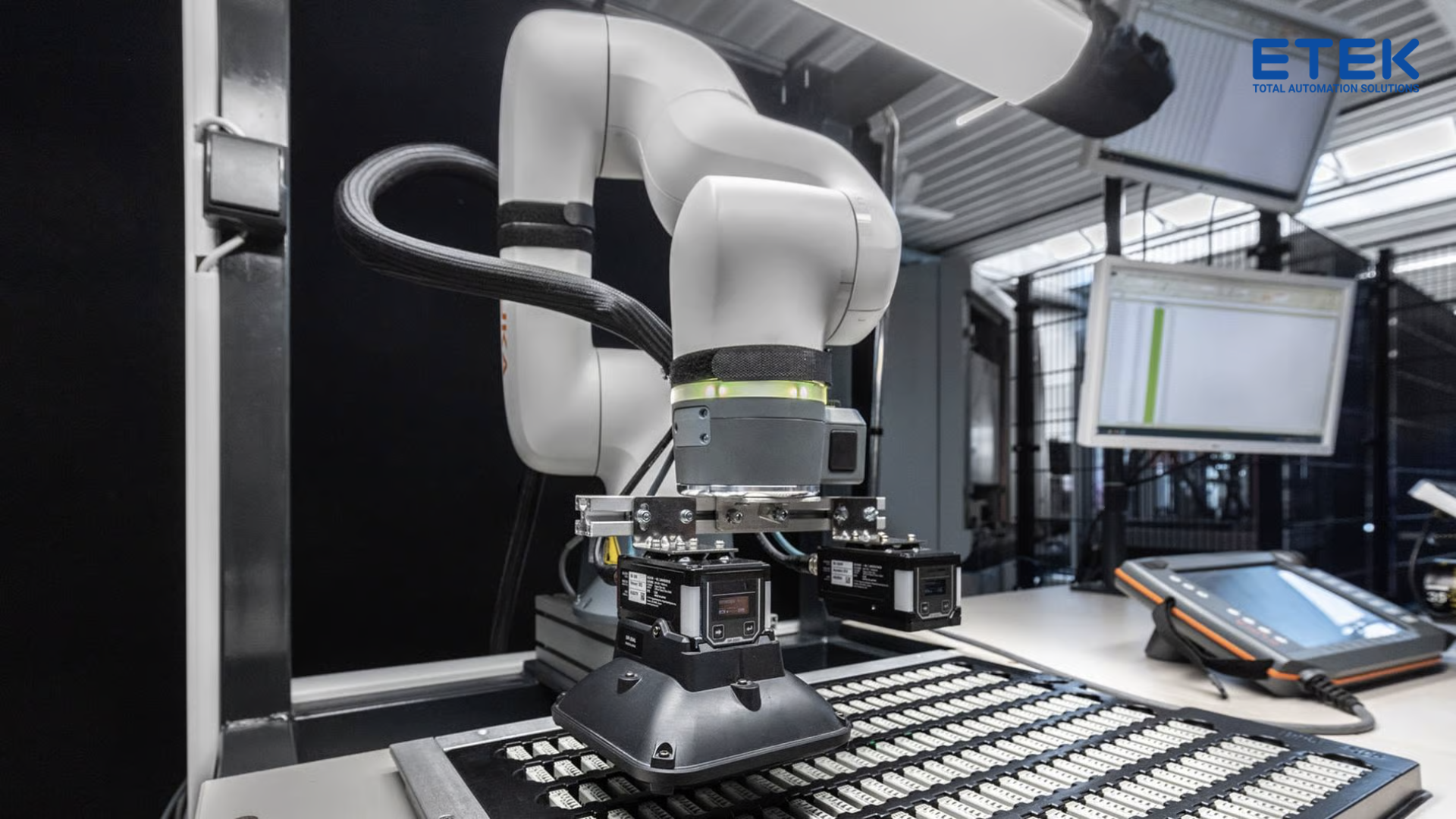

The system uses a collaborative robot (cobot) combined with two industrial cameras to automatically inspect Data Matrix codes laser-marked on plastic product surfaces.

The cobot performs sequential movements to position, locate, and read each code, ensuring that every product is fully inspected before moving on to the next production stage.

When a code is unreadable, incorrectly marked, missing characters, or blurred, the system will automatically stop the production line and precisely indicate the faulty code location, allowing operators to take immediate corrective action.

The system is designed as an integrated solution to ensure maximum performance:

This automation solution inherits exclusive advantages from the LBR iisy cobot series:

What is automation in the consumer goods industry? The food and beverage industry is a sector that produces items such as candy, bottled beverages, etc. In modern society, this industry…

[embed]https://www.youtube.com/watch?v=-Vy6z_l6GcQ[/embed] Application of ABB Robot for automatic car painting Many businesses are hesitant to start considering the application of automation to the production line due to the large initial investment…

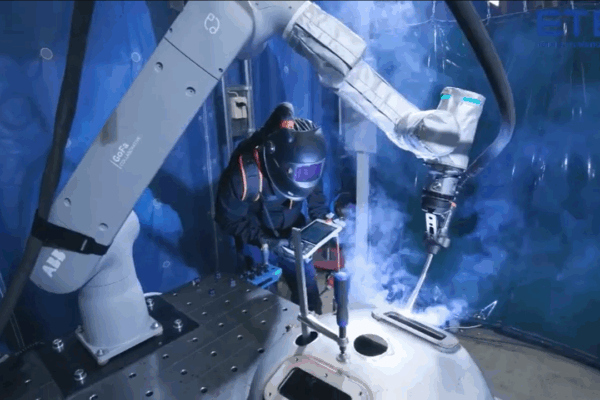

In the industrial kitchen equipment manufacturing industry, the quality of the weld not only determines the durability and safety but also directly affects the aesthetics of the product. In particular,…

In the context of the automobile industry increasingly moving towards automation and high quality , the application of car bumper polishing robots has become an inevitable trend to help businesses improve productivity, optimize costs…