Rising labor costs, inconsistent production efficiency, and errors in processing and packaging are becoming major challenges for instant food manufacturers. Given these difficulties, finding optimal solutions to enhance production efficiency is essential.

As technology continues to transform the food industry, automating production lines not only helps businesses address cost and productivity challenges but also improves product quality and minimizes errors. This strategic approach enables companies to maintain their competitive edge in the market.

So, which stages in the packaging line for processed food can be automated? Let’s explore the details!

An automated packaging line for processed food consists of multiple interconnected machinery systems that handle processing, transportation, packaging, and palletizing. This complex system is customized to meet the specific needs of each business.

The larger the production scale and the more equipment involved, the greater the challenge in synchronizing and optimizing the production process. Ensuring consistent operating speeds across different stages is crucial in determining overall efficiency and product quality.

Conveyor systems play a crucial role in transporting raw materials, semi-finished products, and finished goods between production stages. By reducing manual handling time, conveyors ensure a continuous production process and minimize errors.

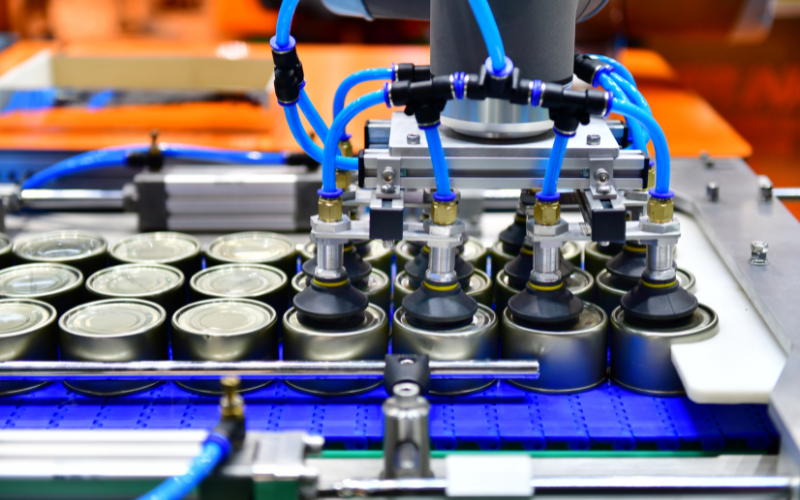

Automated sorting robots accurately and efficiently place products into containers. This reduces labor dependency, optimizes factory space, and enhances operational efficiency.

Proper product packaging is a critical step in processed food packaging lines. Automatic carton sealing machines ensure high precision, reduce packaging time, and enhance the professionalism of the final product.

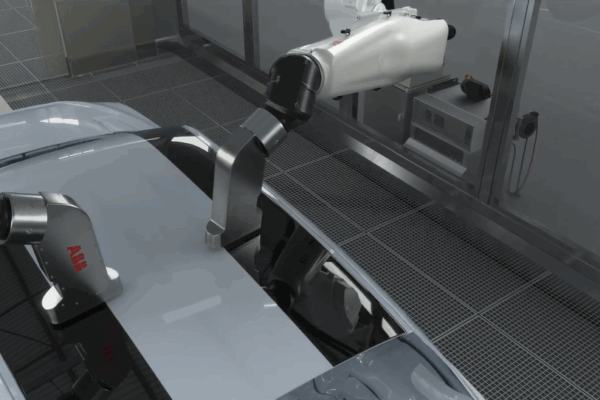

Robotic palletizers assist in stacking cartons onto pallets, reducing manual labor, increasing processing speed, and ensuring uniform packaging for transportation.

AGVs are essential for transporting materials and finished products within factories without human intervention. These vehicles help minimize workplace accidents, optimize logistics, and enhance operational efficiency.

Advancements in technology enable processed food packaging lines to achieve high levels of automation, significantly reducing human intervention. This not only helps businesses cut labor costs but also ensures stability and precision in every production stage.

While investing in a high-quality automated packaging line requires careful consideration, it offers long-term benefits, including lower operational costs, increased productivity, and improved product quality.

Contact ETEK today for expert consultation on the best automation solutions tailored to your business needs and budget!

In the context of the automobile and motorbike market increasingly focusing on personalization, the demand for two-color paint and unique patterns is increasing. However, traditional painting technology still has many…

How Automation Works in the Food and Drink Industry Automation in the food and drink industry involves the application of technology to various production stages. Automation in food processing demands…

The surface treatment industry, also known as surface processing, is a diverse and important industrial field that involves creating surfaces with different properties to meet the requirements of various applications.…

The case erector machine plays a critical role in automating the packaging process, offering a fast and reliable solution for businesses to prepare boxes for product packaging. This article will…