The application of automation technology is a trend that textile companies are particularly interested in and are urgently promoting investment in. This is because the implementation of automation technology is not only a current global trend, but it also leads to significant improvements in labor productivity and product quality.

Automation in the garment industry is a solution that applies technical technologies, robots, modern machinery, and control and monitoring software to gradually replace human labor in each production step. In the context of the world facing pandemics and increasing pressure on labor, companies are increasingly pushing for automation to address these challenges. While the initial investment may be substantial, it will ultimately reduce the long-term financial burden on the company.

Today, with the continuous development of modern technology, most processes in textile production can now apply automation technologies, such as fabric inspection, automated fabric cutting, sewing, folding, and automated inventory management such as:

The garment industry has traditionally been a sector that can yield significant profits if operational costs are optimized. Automation brings many benefits, such as:

The logistics distribution center includes multiple warehouse areas, stacked storage, and AGVs (Automated Guided Vehicles) responsible for transporting goods within the warehouse.

Smart warehouse solution in the footwear manufacturing plant: The project covers over 11,000 m² and can accommodate approximately 130,000 products, with a business scale capable of meeting daily distribution for 1,500 different stores and handling 50,000 e-commerce orders nationwide. It takes only 30 minutes from order creation to product delivery. The entire system can also deliver 5,000 products to offline stores, with a maximum daily delivery capacity of over 300,000 products during peak times to meet customer demand.

The warehouse system is equipped with 26 four-way shuttles for the entire factory, achieving a high efficiency of goods arriving and departing at up to 7,200 packages per day.

Smart warehouse solution in the apparel manufacturing plant: The planned warehouse area is approximately 3,650 m², storing up to 18,000 product boxes.

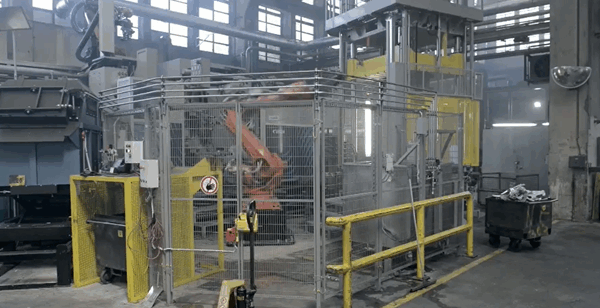

In the metal casting industry , the application of industrial robot systems in post-casting processing is becoming an inevitable trend. This solution helps optimize the entire automatic production process from product picking to cooling. 1. Common…

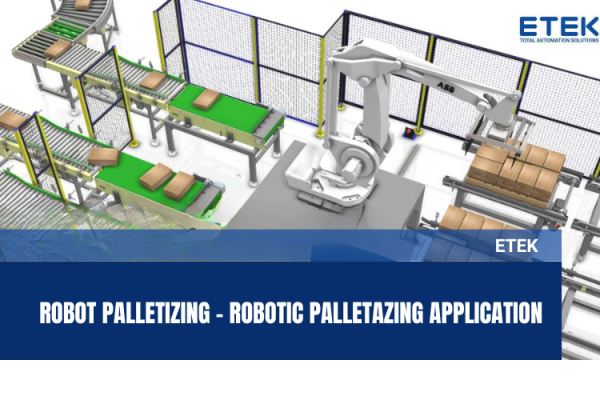

Palletizing robots are one of the industrial robot applications that offer many benefits and are highly appreciated in the manufacturing plant. They are in charge of loading and unloading goods,…

These robotic arms allow for disassembly or even complete replacement, revolutionizing how humans interact with robots and artificial intelligence (AI). The company's website states: "Half a century after the introduction…

What is a robot arm? The robotic arm is programmed to perform a specific task. Additionally, the joints move along the axis of rotation in a certain number of directions.…