The exponential growth of the electric motorcycle and electric vehicle industry demands increasingly sophisticated standards for high-volume productivity, precision manufacturing, and stringent quality control across all battery production processes. At ETEK Automation, we deliver cutting-edge electric motorcycle battery assembly line solutions that seamlessly integrate advanced automation technology, intelligent robotics, and comprehensive testing systems to meet and exceed the most demanding modern technical standards and industry regulations.

Our advanced electric motorcycle battery assembly line serves the rapidly expanding automotive and transportation sectors, manufacturing high-performance batteries for electric vehicles, electric motorcycles, automotive battery systems, and electronic control modules, while also supporting the 3C industries including computing, telecommunications, and consumer electronics with specialized energy modules and IoT applications. The automated system efficiently produces various battery configurations including lithium-ion battery packs, high-capacity energy storage systems, and specialized power modules for electric two-wheelers, electric scooters, e-bikes, and automotive applications. This comprehensive manufacturing capability makes our assembly line the optimal solution for battery manufacturers, electric vehicle companies, and electronics producers seeking reliable, high-volume battery production with superior energy density, safety compliance, and rapid market deployment capabilities.

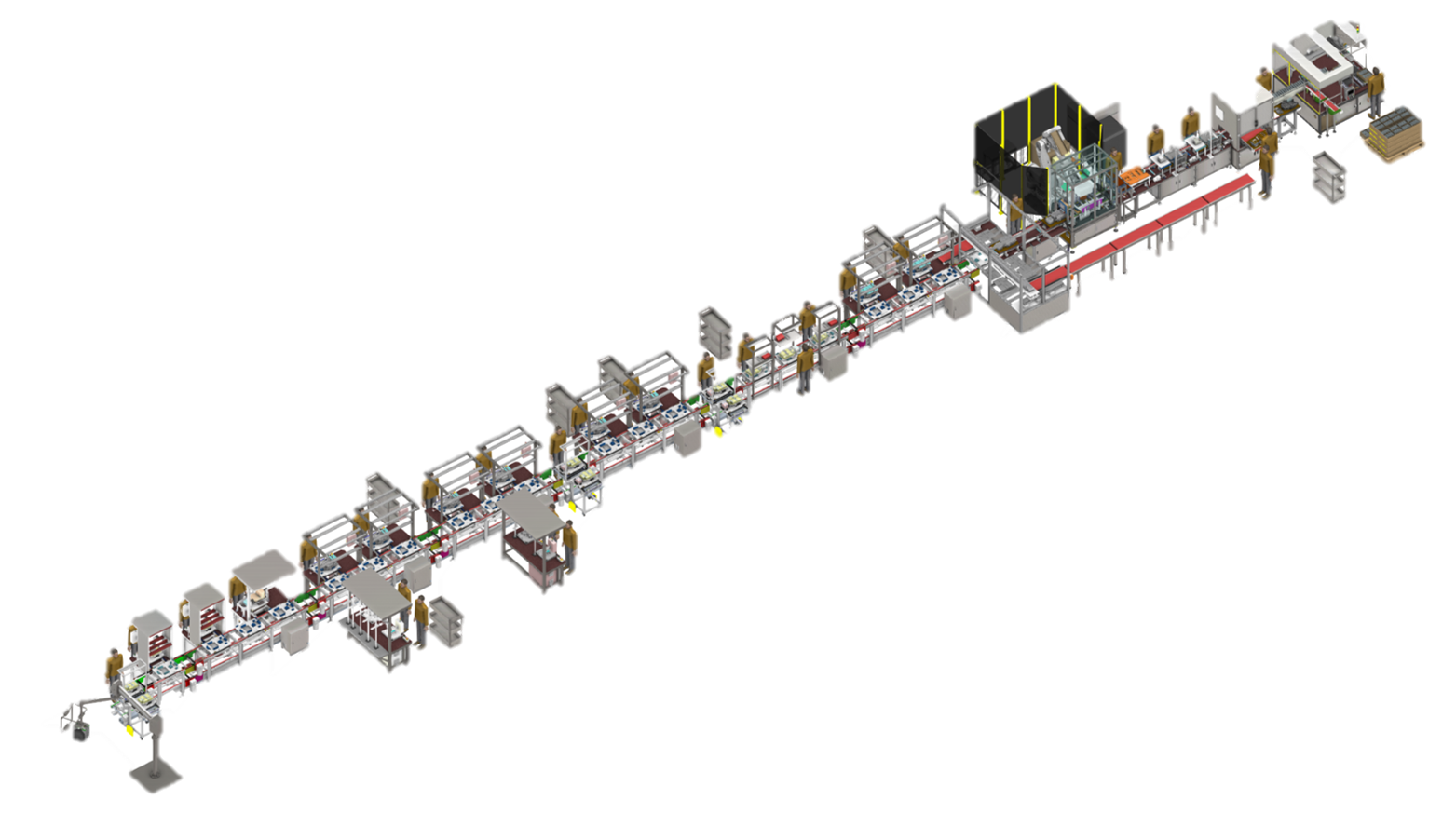

Our precision-engineered assembly line features a 14-step sequential logic design ensuring optimal workflow efficiency and superior battery quality:

1. Sorting: Automated component classification and positioning according to assembly specifications using vision-guided sorting systems and robotic handling equipment.

2. Cell Mounting: Precision robotic installation of battery cells into designated fixtures using force-controlled positioning systems with alignment verification.

3. Camera Inspection: Advanced vision system verification for defects, misalignment, and missing components using high-resolution cameras and AI-powered analysis.

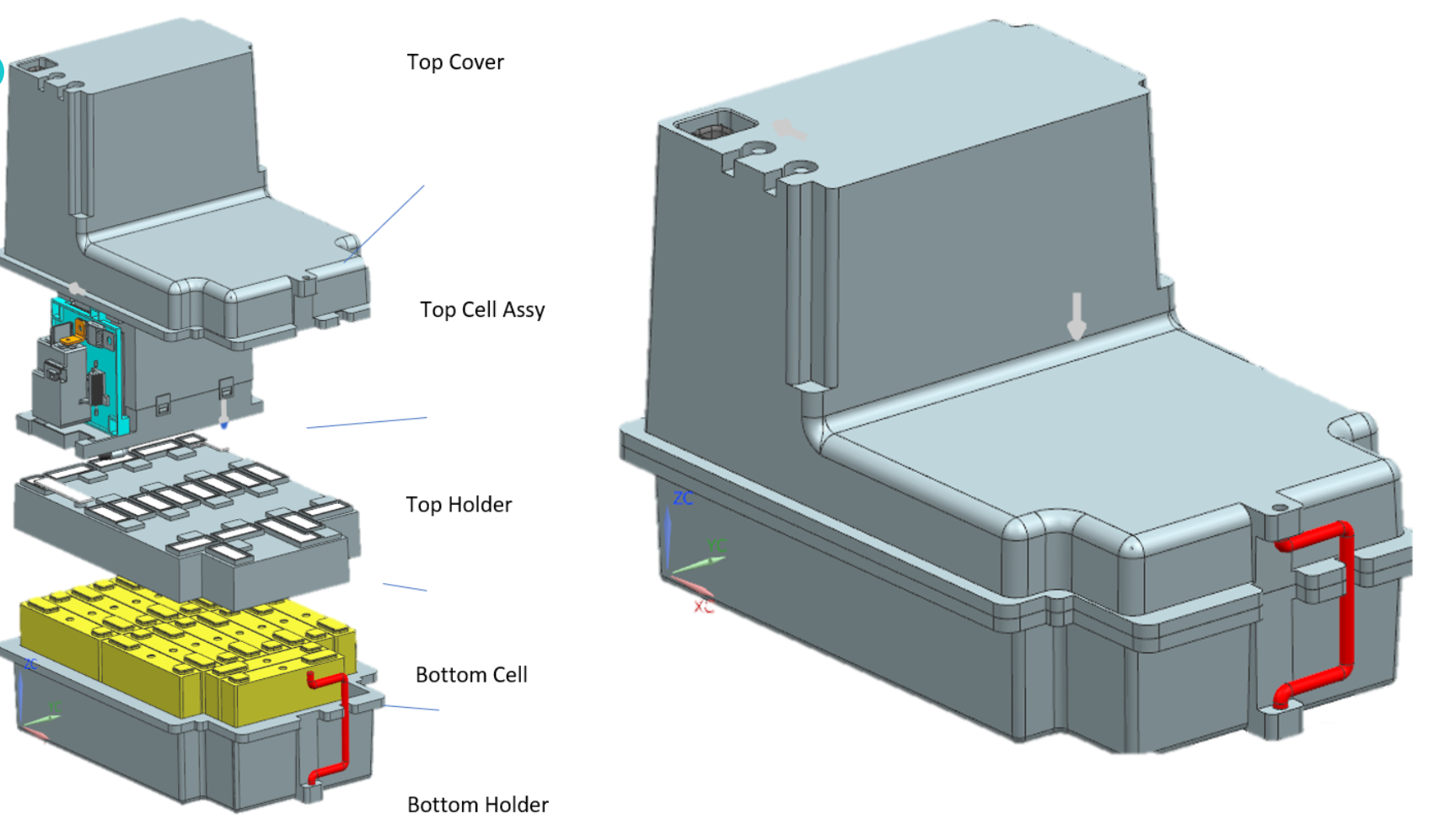

4. Cover and Holder Assembly: Automated robotic installation of protective covers and structural frames using precision positioning systems with torque-controlled fastening.

5. Laser Welding: High-precision non-contact welding technology ensuring robust electrical connections and refined joint quality with real-time monitoring systems.

6. Visual Inspection: Comprehensive detection of physical defects including cracks, misalignment, and surface irregularities using advanced imaging and analysis systems.

7. Sensor Wiring: Automated installation of temperature sensors and monitoring wiring according to technical specifications using robotic cable management systems.

8. Adhesive Application: Precision dispensing of structural adhesives at designated locations for enhanced bonding strength and waterproofing using programmable dispensing systems.

9. Soldering: Automated robotic soldering of electrical circuits and electronic components using temperature-controlled soldering systems with joint quality verification.

10. Screw Fastening: Precision automated fastening according to specified torque standards using multi-spindle systems with real-time torque monitoring and verification.

11. Final Assembly: Comprehensive integration of battery modules into complete systems using robotic assembly with electrical continuity testing and safety verification.

12. Corepack Functional Testing: Advanced evaluation of actual operational performance including capacity testing, voltage verification, and thermal performance analysis using automated testing equipment.

13. Leak Testing and Z-Plug Installation: Comprehensive air-tightness verification and final component installation using pressure testing systems with automated pass/fail classification and sealing verification.

14. EOL (End of Line) Testing: Final comprehensive inspection and performance validation before packaging including safety testing, capacity verification, and quality documentation before shipment.

ETEK AUTOMATION – Your Comprehensive Smart Manufacturing Partner for Advanced Energy Storage Solutions

Our electric motorcycle battery assembly solutions incorporate cutting-edge Industry 4.0 technologies, predictive maintenance capabilities, and scalable automation platforms designed to meet evolving electric vehicle market demands and regulatory requirements.

Transform Your Battery Manufacturing Operations Today

Experience superior automation technology with proven results across numerous successful electric vehicle and energy storage manufacturing installations worldwide.

Access the comprehensive simulation video here:

Contact ETEK for Custom Battery Assembly Solutions:

Address: 189 Phan Trong Tue Street, Thanh Liet Ward, Thanh Tri District, Hanoi, Vietnam

Hotline: 0965 800 166

Email: info@etek.com.vn

Website: https://etekautomation.com.vn

Palletizing robots and pallet-stacking robots are becoming increasingly important in manufacturing plants, effectively fulfilling the final task of automated line for stacking goods onto various types of pallets. The application…

Are you having a headache because of limited warehouse space, slow goods movement, and high operating costs? It's time for your business to need Pallet Flow - a smart, efficient, and…

Entering the industrial revolution 4.0, many businesses around the world are gradually focusing on investing in the development and production of service (support) robots. Industrial welding robots are one of…

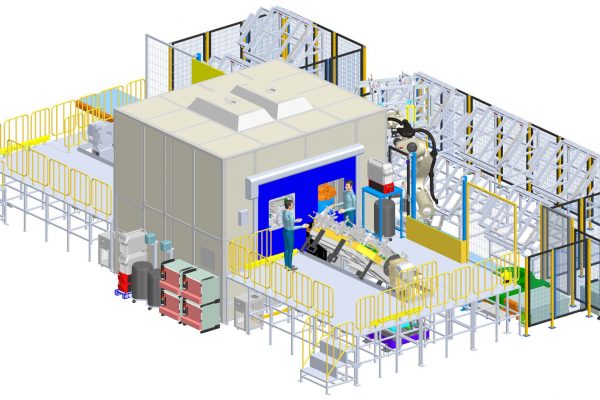

Our Welding Solution offers an advanced, fully automated system for performing a wide range of welding tasks with precision and consistency. This solution is ideal for industries that require strong,…