In the journey of digital transformation and building smart factories, many automobile manufacturing and assembly enterprises in Vietnam have begun to invest heavily in automation technologies. One of the important steps is to apply the AGV (Automated Guided Vehicle) system to replace the traditional method of transporting materials by human labor and mechanical tractors.

The deployment of hundreds of AGVs at a large-scale automobile manufacturing and assembly plant in Vietnam is a clear demonstration of this trend. The project was carried out by ETEK – a pioneer in the field of automation solutions , with the goal of not only improving operational efficiency, but also helping customers gradually approach the smart factory model according to international standards.

Before the AGV system was deployed, all the transportation of components, materials, and finished products in the factory was done by humans – through handcarts or tractors. This method has many problems:

Modern AGVs incorporate a variety of navigation technologies, depending on the requirements and complexity of the environment:

In automobile assembly plants, AGVs often take on tasks such as:

Thanks to its precise, continuous and safe operation, AGVs help maintain a steady flow of materials , limiting bottlenecks and delays in the internal supply chain.

One of the outstanding applications of AGV self-propelled vehicles is integration with smart warehouse systems :

AGVs serve as the “backbone” of smart warehouse transportation operations, contributing to the construction of a modern, flexible and scalable logistics system.

See more about ETEK’s projects HERE

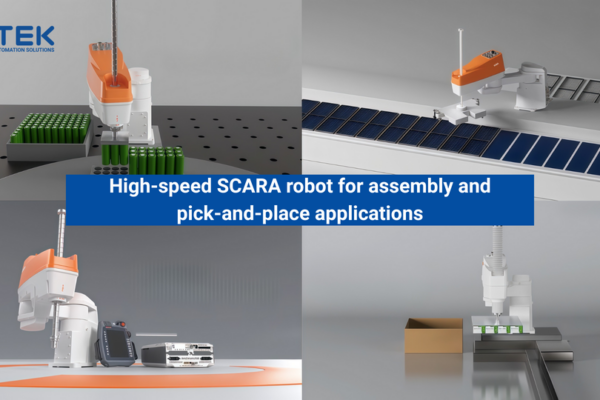

OVERVIEW The KR SCARA robot is a high-performance industrial robot, distinguished by its powerful operation and exceptional speed in modern production lines. For applications such as small-part assembly, material handling,…

In the era of digital transformation, the electronics industry is experiencing rapid growth in both scale and technical demands. To meet increasing requirements for productivity, precision, and quality control, automation…

What is a robot arm? The robotic arm is programmed to perform a specific task. Additionally, the joints move along the axis of rotation in a certain number of directions.…

In the era of smart manufacturing, flexible and safe automation is the key to improving productivity and reducing costs. ETEK introduces the autonomous vehicle combined with robotic arm (cobot) solution…