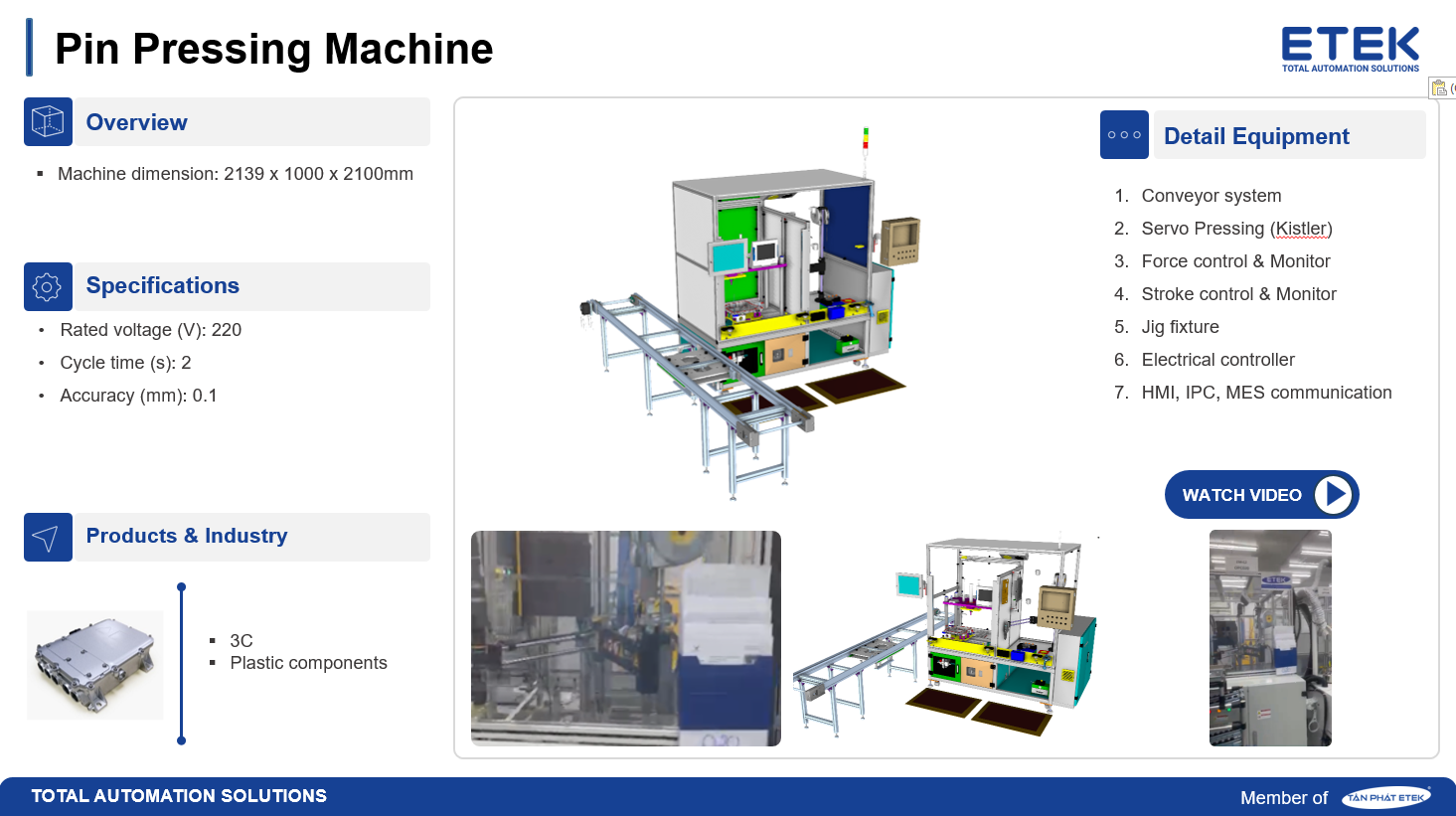

In industrial production lines, every assembly step plays a vital role in ensuring the quality of the final product. One of the key steps is pin pressing, which helps secure parts in place, ensuring both assembly precision and structural durability.

To meet this demand, ETEK has researched and developed an automatic pin pressing machine, specifically designed for high-precision assembly stages such as controller units, battery frames, and handheld devices. Automating this step not only improves productivity but also ensures mechanical durability, aesthetic appeal, and product consistency throughout the entire production line.

Machine Components

pin pressing machine

The automatic pin pressing machine is designed with an optimized structure to ensure accuracy, stability, and high integrability in modern production lines. The main components include:

In many manufacturing enterprises today, the gluing process is still done manually or semi-automatically. This leads to a series of limitations such as difficulty in controlling the amount of glue,…

In modern manufacturing, packaging automation optimizes processes, enhances productivity, and reduces costs. Automated packaging systems handle tasks like filling, sealing, labeling, and palletizing with high precision and speed, making them…

In modern manufacturing, repetitive tasks such as picking and transferring products between production stages not only consume time but also waste human resources. The High-Speed Pick and Place System emerges…

Are you looking for an efficient automation solution for your plastic molding station? ETEK provides comprehensive automated robot solutions, helping businesses improve productivity, reduce labor costs and ensure stable product…