The Robotic Milling Solution utilizes industrial robots to perform high-precision milling and shaping operations with consistent accuracy and stable performance. The solution enables manufacturers to increase productivity, enhance design flexibility, and reduce reliance on manual labor. In addition to foam machining, the system supports a wide range of materials including metals, wood, plastics, and composite materials, meeting diverse manufacturing requirements.

A complete robotic milling system consists of the following key hardware and software components:

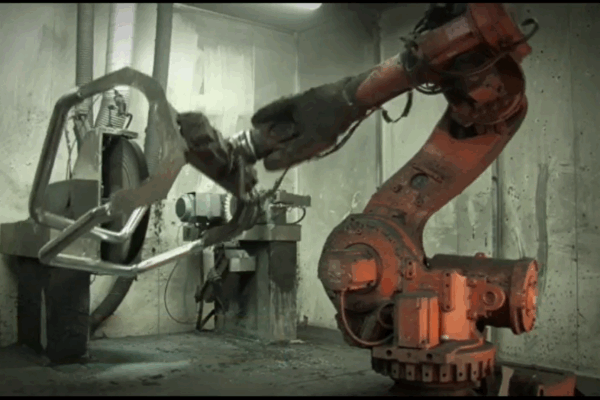

Industrial Robotic Arm: A high-rigidity industrial robot with six axes or more, providing flexible kinematics and extended reach. The robotic arm serves as the core of the milling solution, enabling precise machining of free-form surfaces, complex 3D geometries, and intricate workpieces beyond the capabilities of conventional machine tools.

Robot Controller and Automation Control System: The robot controller acts as the central control unit of the automated milling system. It processes CAD/CAM data, calculates toolpaths, and synchronizes multi-axis robot motion to ensure accurate, stable, and repeatable milling operations.

Milling Spindle and Cutting Tool System: The spindle unit generates the required cutting force and performs material removal during the milling process. Cutting tools and spindle configurations are selected according to material type and machining requirements, ensuring optimal cutting speed, dimensional accuracy, and surface quality.

Auxiliary Automation Components: Including Automatic Tool Changer (ATC) systems, tool measurement sensors, and robot linear tracks. These components enable fully automated milling operations, minimize downtime, expand the machining envelope, and improve overall system efficiency.

The KUKA robotic milling process is based on the integration of digital engineering and precise robotic motion control:

CAD/CAM Programming and Offline Simulation: 3D models are created using CAD software, and toolpaths are generated via CAM systems. Due to the robot’s multi-axis kinematics, offline simulation is required to avoid singularities and prevent collisions within the working envelope.

G-Code Execution via KUKA.CNC: G-code is transferred directly to the robot controller through the KUKA.CNC software package. The system performs coordinated multi-axis interpolation, allowing the milling tool to follow complex 3D trajectories with smooth motion characteristics comparable to dedicated CNC machine tools.

Milling Operation: The high-speed spindle performs cutting operations while the robotic arm moves dynamically to access undercuts, deep cavities, and curved surfaces. This enables the machining of large-scale workpieces and complex geometries that are challenging for traditional CNC machines.

Industrial robotic milling is widely applied across various industries, including:

The Robotic Milling Solution is a reliable and flexible manufacturing solution for companies requiring high-precision machining across multiple materials. With seamless integration into automated production lines, the system improves productivity, enhances product quality, and supports the requirements of modern, Industry 4.0–ready manufacturing environments.

Contact ETEK for more detailed consultation

Let ETEK partner with you from assessment – design – manufacturing – installation – technology transfer.

Address: 189 Phan Trong Tue Street, Thanh Liet Ward, Thanh Tri District, Hanoi, Vietnam

Hotline: 0965800166

Email: info@etek.com.vn

Website: https://etekautomation.com.vn

Introduction to the Automatic Packaging Line Automatic packaging lines have become an essential part of modern manufacturing plants, especially in industries such as food and beverage, consumer goods, pharmaceuticals, and…

In the context of the automobile industry increasingly moving towards automation and high quality , the application of car bumper polishing robots has become an inevitable trend to help businesses improve productivity, optimize costs…

The Pick to Light system integrated into automotive assembly plants is an efficient solution that helps workers quickly and accurately select components, reducing errors and improving productivity. Understanding the Pick…

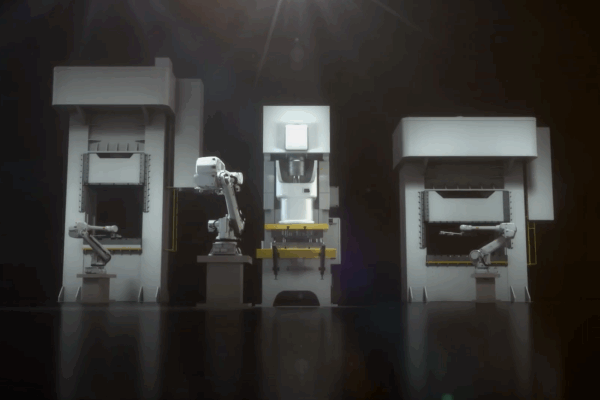

Are you looking for a press area automation solution? The stamping station automation solution deployed by ETEK will be the ideal choice for manufacturing enterprises that want to increase productivity -…