In the era of modern industry constantly developing, automation technology has been reshaping the way manufacturing industries operate, helping businesses improve efficiency and reduce costs. In particular, in the automobile manufacturing industry – where precision and quality are highly required, car painting robots stand out as a breakthrough solution, bringing high precision and outstanding quality to the spraying process paint

Painting robots not only help to finish product surfaces evenly, but also optimize resources and increase production flexibility. So what is a car painting robot and what benefits does it bring? Let’s explore details with ETEK through the article below.

Car painting robots are automatic devices programmed to perform paint spraying processes with high precision. They are equipped with:

Car painting robot technology not only helps improve product quality but also meets strict production requirements in the modern auto industry

With the continuous improvement of painting technology, painting equipment and the advent of paint robots, the traditional paint industry’s production method has changed, reducing the paint industry’s dependence on labor and reducing production costs

Car painting robots produce flawless, even coatings across entire vehicles, enhancing product quality and the overall value of each car. High precision minimizes uneven paint errors, ensuring durability and aesthetic appeal.

A single operator can oversee and control multiple robots, eliminating the need for a large workforce. This reduces labor costs, enhances efficiency and shortens production time.

With precise spraying technology, automotive painting robots reduce paint wastage and emissions during the process. This contributes to environmental protection and lowers material costs, promoting sustainable production practices.

Paint contains harmful chemicals that can negatively impact human health with prolonged exposure. By replacing humans in hazardous tasks, painting robots significantly reduce contact with toxic paint particles. This ensures worker safety and minimizes the risk of workplace accidents.

In the automotive industry, car painting robots have several critical applications, such as:

With over 18 years of expertise in automation, ETEK proudly supplies high-quality automotive painting robots that offer significant benefits to businesses:

Learn more about ETEK’s Painting Robots here: https://etekautomation.com.vn/painting-solution-overview

What is Delta robot? Robot delta (Spider Robot) is a line of robots with a distinct design compared to other stationary industrial robots. The name delta comes from its inverted…

A thermal transfer printer ( also known as a TTO - Thermal Transfer Overprinting machine) is a device that uses thermal transfer technology to print on packaging surfaces or other…

The cobot-based automatic machine tending solution feeds raw parts and finished products into CNC machines, replacing repetitive, high-precision tasks while ensuring safe collaboration with human workers. What is Cobot Machine…

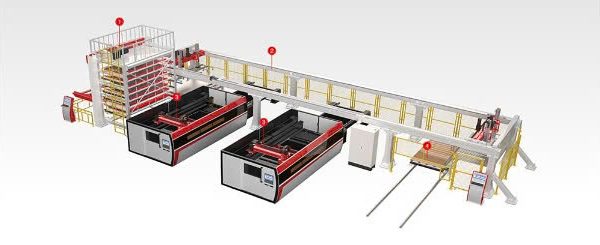

Our Metal Processing Solution offers cutting edge technology for cutting, shaping, and forming metal parts with the highest precision. This solution utilizes advanced machinery such as laser cutters, CNC machines,…