The surface treatment industry, also known as surface processing, is a diverse and important industrial field that involves creating surfaces with different properties to meet the requirements of various applications. Surface treatment methods include techniques such as sandblasting, metal plating, coating, plasma treatment, and many others.

The primary purpose of the surface treatment industry is to increase durability, hardness, wear resistance, corrosion resistance, chemical resistance, heat resistance, ultraviolet resistance, gamma resistance, improve adhesion, scratch resistance, enhance aesthetics, and improve the physical and chemical properties of surfaces. The applications of the surface treatment industry are diverse, ranging from automotive manufacturing, aerospace, shipbuilding, electronics production, pharmaceuticals, to jewelry making and household products.

ETEK provides surface treatment technology and equipment across various industries:

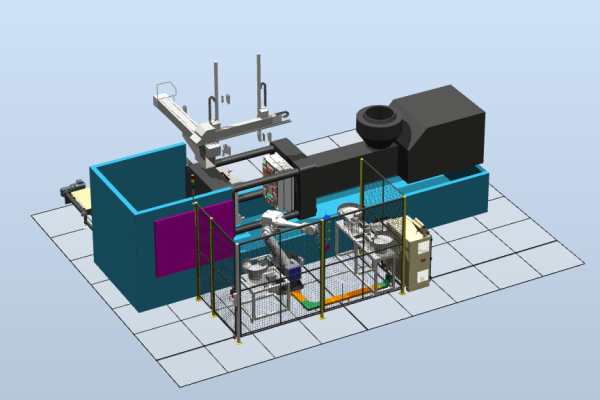

To meet the solutions for a variety of product industries, we offer equipment with specialized cleaning technology that creates superior and optimized surface treatment capabilities.

Completely automated cleaning system with high process flexibility and precise formula control, where users can adjust all process sequences for each cleaning requirement.

Flexible modular structure with a simple motion mechanism, capable of handling overall cleaning applications.

Front-load design for a fully enclosed cleaning system, including a completely sealed single chamber, capable of executing flexible processes with high efficiency.

Fully enclosed front-load cleaning system, including one or multiple customizable chambers capable of handling processes from simple to medium complexity.

Completely enclosed continuous conveyor cleaning system consisting of multiple tanks, capable of providing high throughput cleaning applications and efficient processes.

The demand for robotic welding and industrial welding robots is continuing to increase, especially in Vietnam – a country in the process of industrialization and modernization. Why is robotic welding…

What is automation in the consumer goods industry? In the context of fierce competition, automation is not only a trend but also a key solution for businesses to enhance their…

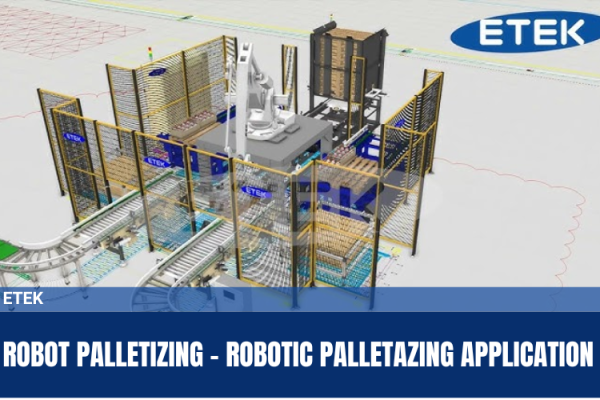

In industrial production, one of the stages prioritized for automation is the loading and unloading of go ods... From now on, businesses should turn automation solutions into their competitive advantage…

In a medical equipment warehouse, accuracy, hygiene, and processing speed are not just goals—they are vital. A single picking error can disrupt the entire supply chain and directly affect the…