Palletizing is the process of loading products onto pallets on demand. In the final stage of the packaging line, the robot performs the task of bagging, the robot loads the pallet with a flexible arm and a multi-functional suction gripper.

Palletizing robots with multiple loading points (SKUs) and outputs (outputs) perform better than specialized palletizers.

A palletizing robot, also known as a palletizing robot, is a device that automates the process of palletizing. The application can operate according to previously programmed programs or according to instructions from the control personnel. Palletizing robots are used in factories that produce goods to increase productivity and reduce labor costs.

The structure of the palletizing robot must always be suitable for the size and weight of the product to always ensure the stability of the pallet when moving.

The above basic elements form an efficient, accurate palletizing system for complex tasks such as loading goods on pallet racks.

The palletizing robot has the following characteristics:

Palletizing robots are used in many different manufacturing fields, including:

ETEK Automation Solutions Joint Stock Company provides robotic palletizing solutions that ensure compliance with business requirements and costs.

With nearly 20 years of experience in the field of automation, ETEK is committed to:

FOR MORE INFORMATION, PLEASE CONTACT ETEK AUTOMATION SOLUTIONS JOINT STOCK COMPANY

What is Sealing? Sealing is the process of creating a protective layer or barrier to prevent the intrusion or leakage of liquids, gases, dust, or other contaminants between surfaces or…

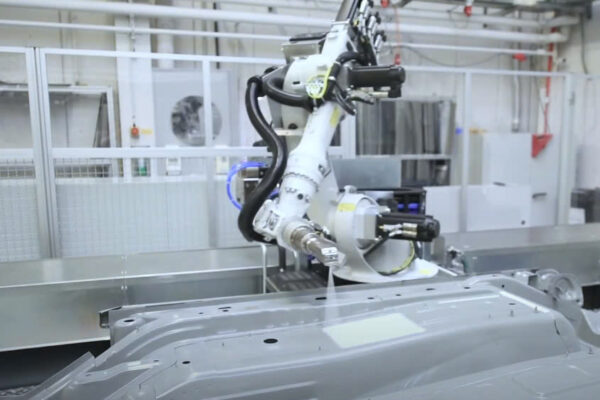

In the journey of digital transformation and building smart factories, many automobile manufacturing and assembly enterprises in Vietnam have begun to invest heavily in automation technologies. One of the important…

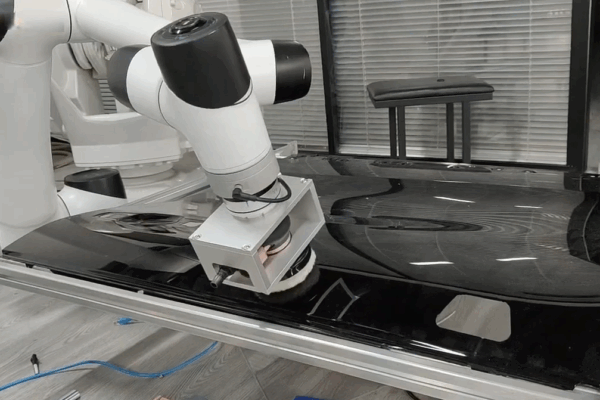

In the automotive industry, polishing plays a key role in ensuring that the product surface meets perfect standards before entering the next stages such as painting, assembly or shipping. Robotic polishing…

As manufacturing and logistics businesses increasingly focus on efficiency and accuracy, smart warehouse solutions are becoming a strategic choice to improve performance, save space and ensure safe operations. The Kardex…