In the metal casting industry , the application of industrial robot systems in post-casting processing is becoming an inevitable trend. This solution helps optimize the entire automatic production process from product picking to cooling.

In the metal casting industry, especially in sectors like automotive and precision engineering, post-cast product processing presents multiple challenges that affect both productivity and workplace safety:

→ To overcome these challenges, many manufacturers are turning to automatic robots, which can operate safely in harsh environments, deliver consistent performance, and greatly accelerate processing speed.

The application of robot automation in post-casting stages brings transformative improvements. Key solutions include:

→ These automatic robot solutions not only modernize the production process but also enhance long-term reliability, consistency, and worker safety across the board.

The implementation of automatic robots in post-cast handling brings a wide range of tangible benefits:

Automatic robots are now widely adopted in a range of industrial environments, including:

These real-world applications prove the efficiency and scalability of automatic robot systems in optimizing post-cast product processing across various industries.

These robotic arms allow for disassembly or even complete replacement, revolutionizing how humans interact with robots and artificial intelligence (AI). The company's website states: "Half a century after the introduction…

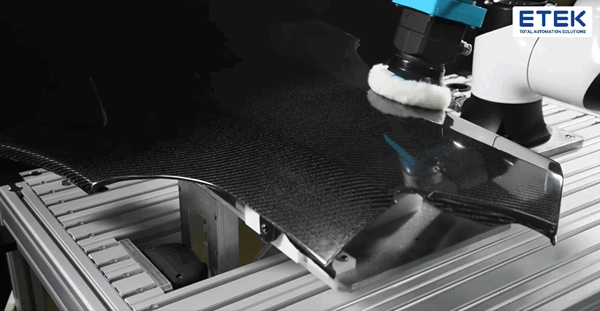

In the era of smart manufacturing, metal polishing automation is no longer a trend but has become a core solution to help factories improve product quality, optimize costs and increase…

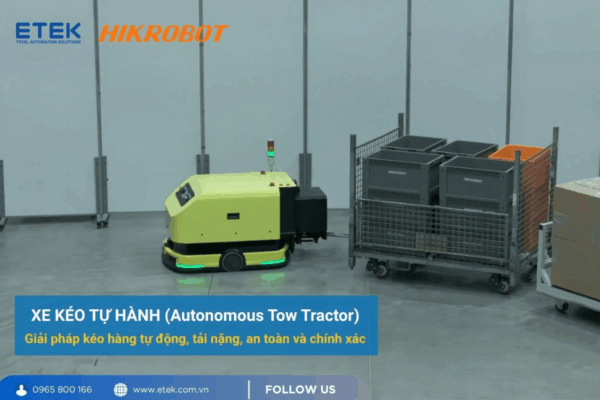

In the context of modern manufacturing increasingly requiring high productivity, safety and comprehensive automation, Autonomous Mobile Robots (AMRs) are gradually becoming an indispensable part of the internal logistics chain at the factory.…

In modern production environments, accuracy and speed are key factors in determining efficiency. The automatic bottle feeding machine (Bottle Feeding) has emerged as an outstanding solution to automate the bottle…