Automatic packaging lines have become an essential part of modern manufacturing plants, especially in industries such as food and beverage, consumer goods, pharmaceuticals, and cosmetics. The use of automatic packaging systems not only enhances work efficiency but also ensures product quality, saves costs, and increases business competitiveness. This article provides a detailed overview of automatic packaging lines, common types, and the benefits they bring to manufacturers.

An automatic packaging line is a system of machines and equipment programmed to perform packaging processes without direct human intervention. It includes multiple stages such as packaging, labeling, quality inspection, and carton sealing.

Common Technologies in Automatic Packaging Lines:

Automatic packaging lines operate continuously without interruption, significantly increasing productivity and operational efficiency. They can package thousands of products per hour — a level of performance difficult for manual labor to achieve.

Although the initial investment may be high, automatic packaging systems help reduce labor costs and minimize packaging errors in the long term. This is particularly important in a competitive market where labor costs continue to rise.

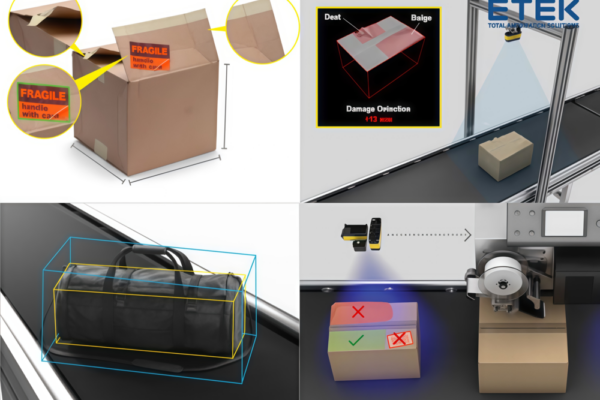

Automatic systems ensure that products are packaged uniformly and precisely, improving quality consistency and brand image. Integrated inspection systems detect and eliminate defective products, ensuring only qualified goods reach consumers.

In the food industry, automatic packaging lines help minimize human contact with products, thereby ensuring food safety and hygiene. They also reduce contamination risks and enhance product preservation.

.png)

In the Food and Beverage Industry

In the Pharmaceutical Industry

In the Cosmetics Industry

In the Household Goods Industry

In the Garment Industry

Automatic packaging lines are an optimal automation solution for improving production efficiency, reducing costs, and ensuring product quality. Investing in such systems not only strengthens a company’s competitiveness but also meets strict standards of safety, hygiene, and quality in modern manufacturing.

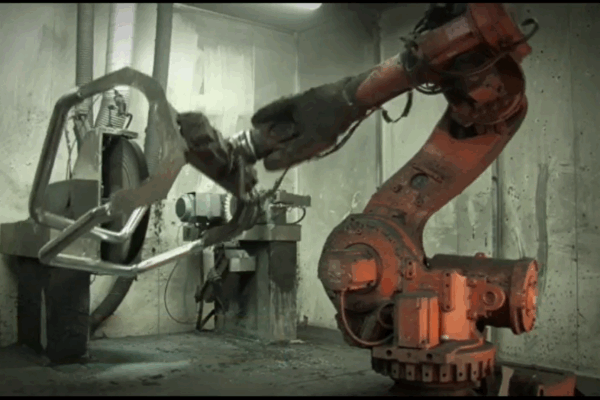

In the context of the automobile industry increasingly moving towards automation and high quality , the application of car bumper polishing robots has become an inevitable trend to help businesses improve productivity, optimize costs…

Smart warehouses is a storage system that utilizes advanced technologies such as automation, the Internet of Things (IoT), Artificial Intelligence (AI), and Big Data to efficiently and accurately manage storage,…

The 3D-A1000 dimensioning system is a compact industrial smart camera capable of capturing moving objects in both 2D and 3D. It is equipped with powerful vision tools that enable automation…

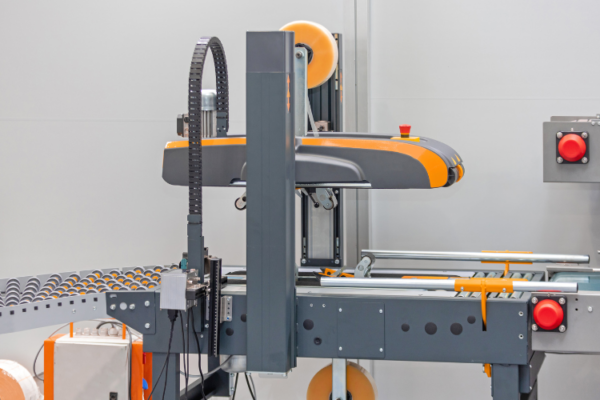

In modern production processes, ensuring that cartons are securely, aesthetically, and efficiently sealed is a critical factor in improving product quality and optimizing packaging lines. The case sealer (carton sealing…