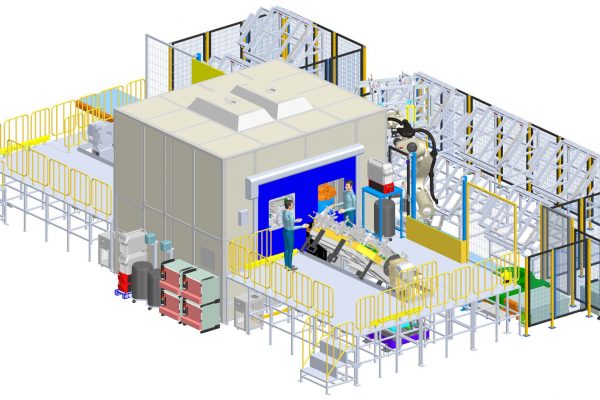

In the era of Industry 4.0—where production speed, product quality, and operational efficiency are key to enhancing competitiveness—manufacturers are increasingly investing in automated systems. One of the most advanced and effective solutions today is the electrostatic powder coating line. This technology not only optimizes production costs but also ensures superior quality and environmental friendliness.

With nearly 20 years of experience in industrial automation, ETEK proudly delivers a comprehensive automated electrostatic powder coating solution. Our systems have been widely implemented in automotive, motorcycle, and mechanical manufacturing plants across the country.

An electrostatic powder coating line is an automated system that applies powder coating using electrostatic force. The powder is positively charged, while the product surface is negatively charged. This charge difference creates an electrostatic attraction, allowing the powder to adhere evenly and firmly to the surface. The coated product is then cured in a heating oven, causing the powder to melt and form a durable, hard, and aesthetically pleasing finish.

Compared to traditional painting methods, electrostatic powder coating is technically more efficient, cost-effective, and environmentally friendly.

Optimized production capacity: ETEK’s system can handle over 750,000 product units per year, meeting high-volume production demands.

High automation: Up to 95% automation reduces the need for manual labor, improves precision, and minimizes operational errors.

Long-term cost savings: The system allows reuse of excess powder and saves energy through an optimized curing process.

Environmentally friendly: No use of volatile solvents or emission of harmful gases.

Flexible applications: Compatible with various metal materials such as steel, aluminum, and other industrial components.

Loading – Products are placed onto the automated conveyor system.

Pretreatment – Surfaces are cleaned of oil and rust using specialized industrial chemicals.

Dry Off Oven – Products are dried after pretreatment.

Powder Coating Booth – Powder is sprayed evenly using electrostatic spray guns.

Curing Oven – Heated to 180–200°C to melt and bond the powder coating.

Cooling – Products are cooled to stabilize their condition.

Inspection – Coated surfaces are checked for thickness, adhesion, color, and overall finish quality.

Unloading – Products are removed for packaging or moved to the next stage of production.

Strong adhesion and high durability: Resistant to corrosion, scratching, UV rays, and harsh environments.

Excellent aesthetics: Smooth, even, and glossy coating without runs or bubbles.

Operational cost savings: Reusable powder and reduced environmental treatment costs.

Easy maintenance: Modular design allows for easy replacement and upgrades.

High initial investment: Requires a complex system including curing ovens, spray booths, and conveyors.

Limited to conductive materials: Most effective on metals.

Technical operation requirements: Requires skilled technicians to manage temperature, air pressure, and coating thickness.

Automotive & Motorcycles: Coating of seat frames, chassis, and load-bearing metal components.

Mechanical & Metalworking: Surface protection for parts, electrical cabinets, and structural frames.

Supporting Industries: Precision parts with high aesthetic and durability requirements.

Read More:

In the industrial kitchen equipment manufacturing industry, the quality of the weld not only determines the durability and safety but also directly affects the aesthetics of the product. In particular,…

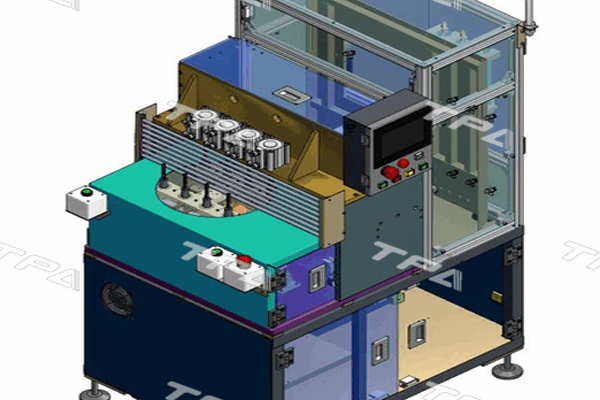

What is Automated Glue Applicator? Glue application automation is the use of glue application robots, cobots (collaborative robots) and intelligent control systems to perform the glue application process on the product…

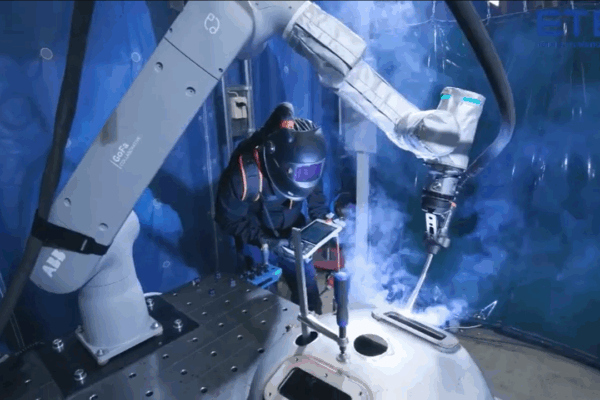

Our Welding Solution offers an advanced, fully automated system for performing a wide range of welding tasks with precision and consistency. This solution is ideal for industries that require strong,…

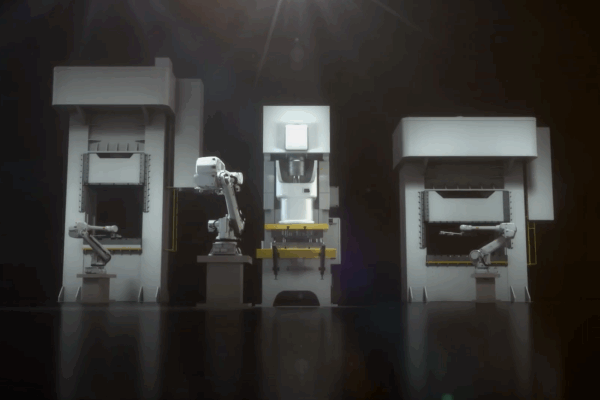

Are you looking for a press area automation solution? The stamping station automation solution deployed by ETEK will be the ideal choice for manufacturing enterprises that want to increase productivity -…