In the era of digital transformation, the electronics industry is experiencing rapid growth in both scale and technical demands. To meet increasing requirements for productivity, precision, and quality control, automation in electronics manufacturing has become the strategic key for businesses to accelerate production and maintain competitive advantage.

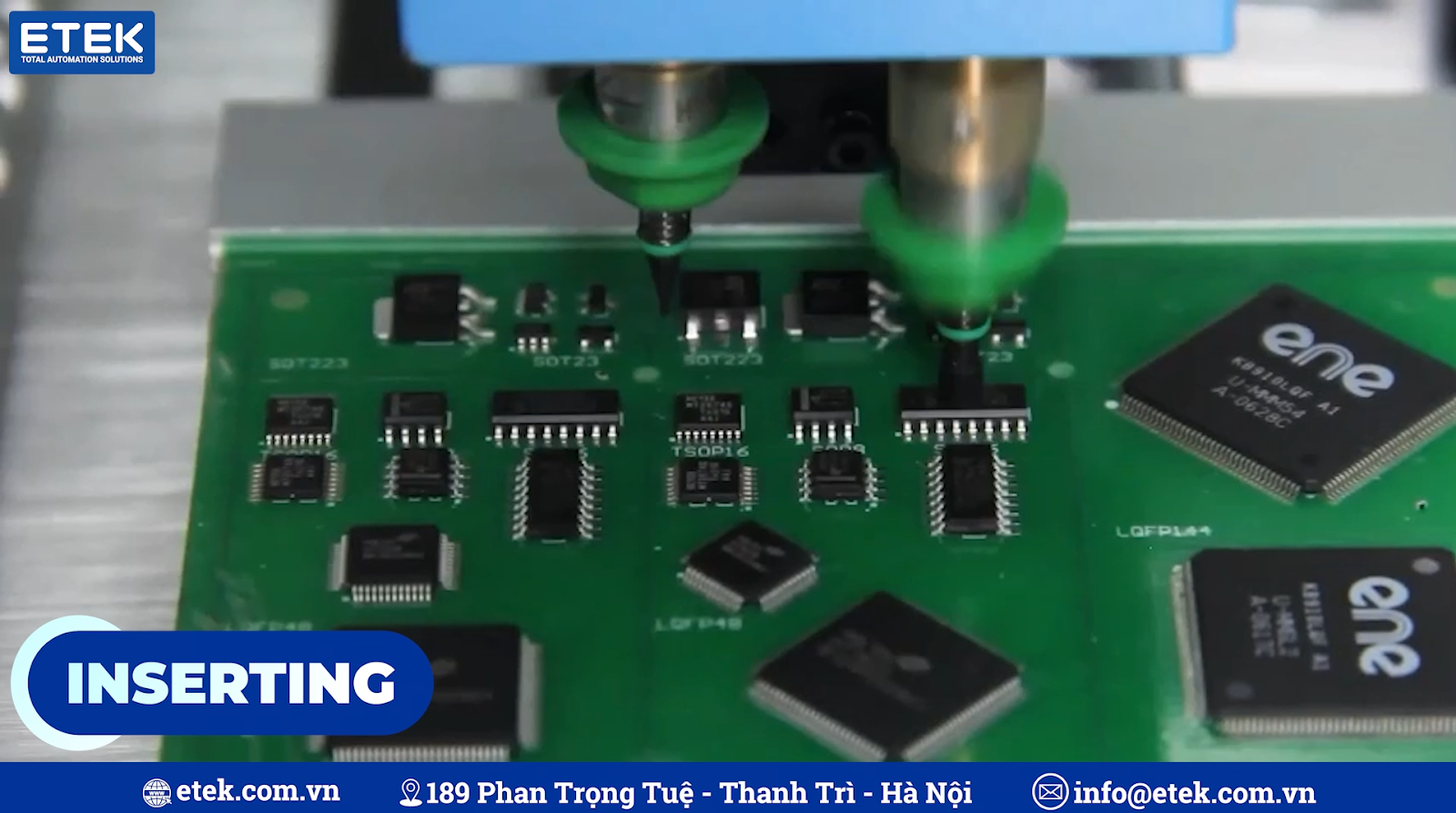

The process of automatically placing electronic components (ICs, capacitors, resistors, etc.) onto PCBs using specialized equipment or robots.

Benefits:

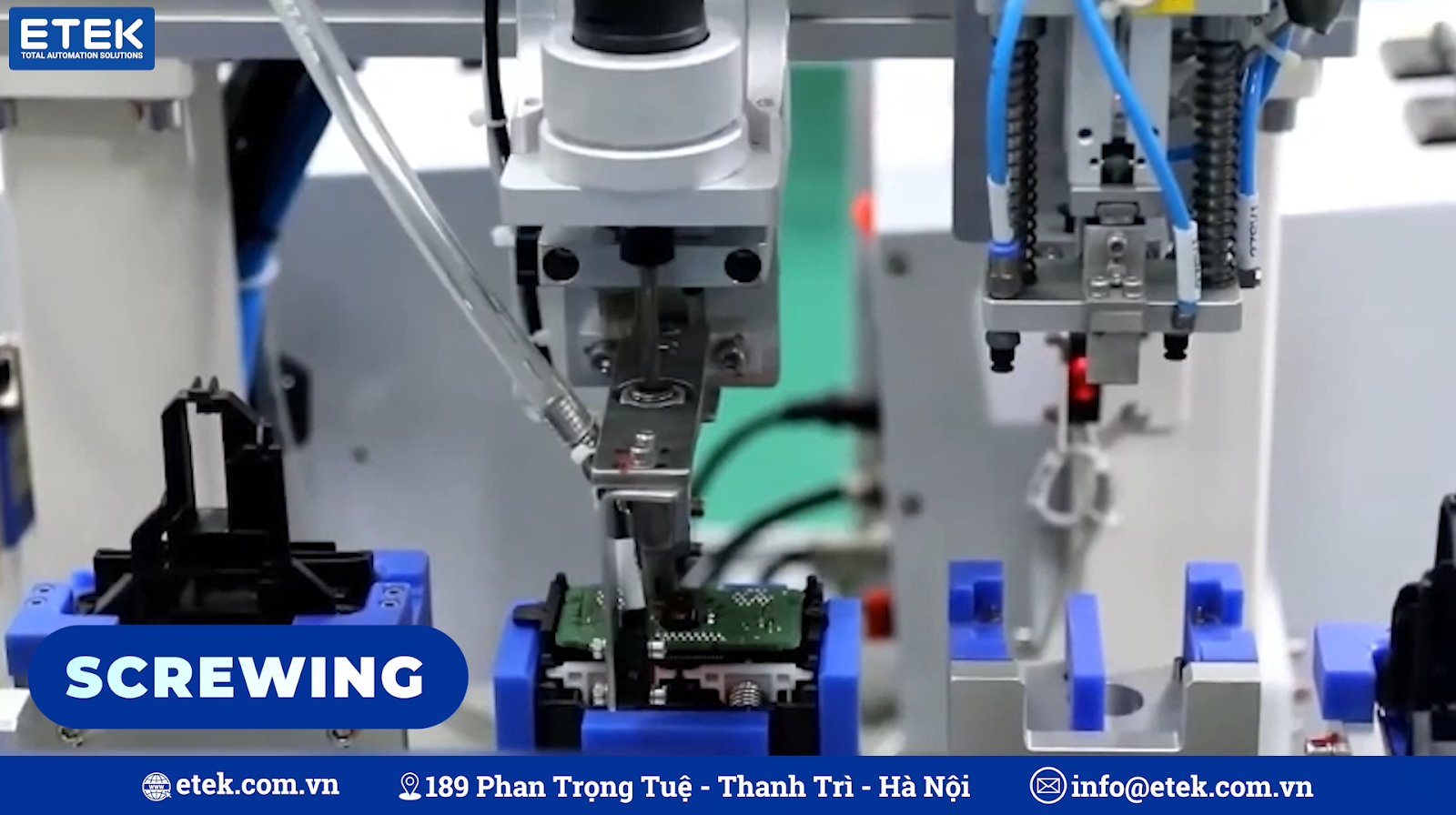

Using an automated system to tighten screws with pre-set torque values.

Benefits:

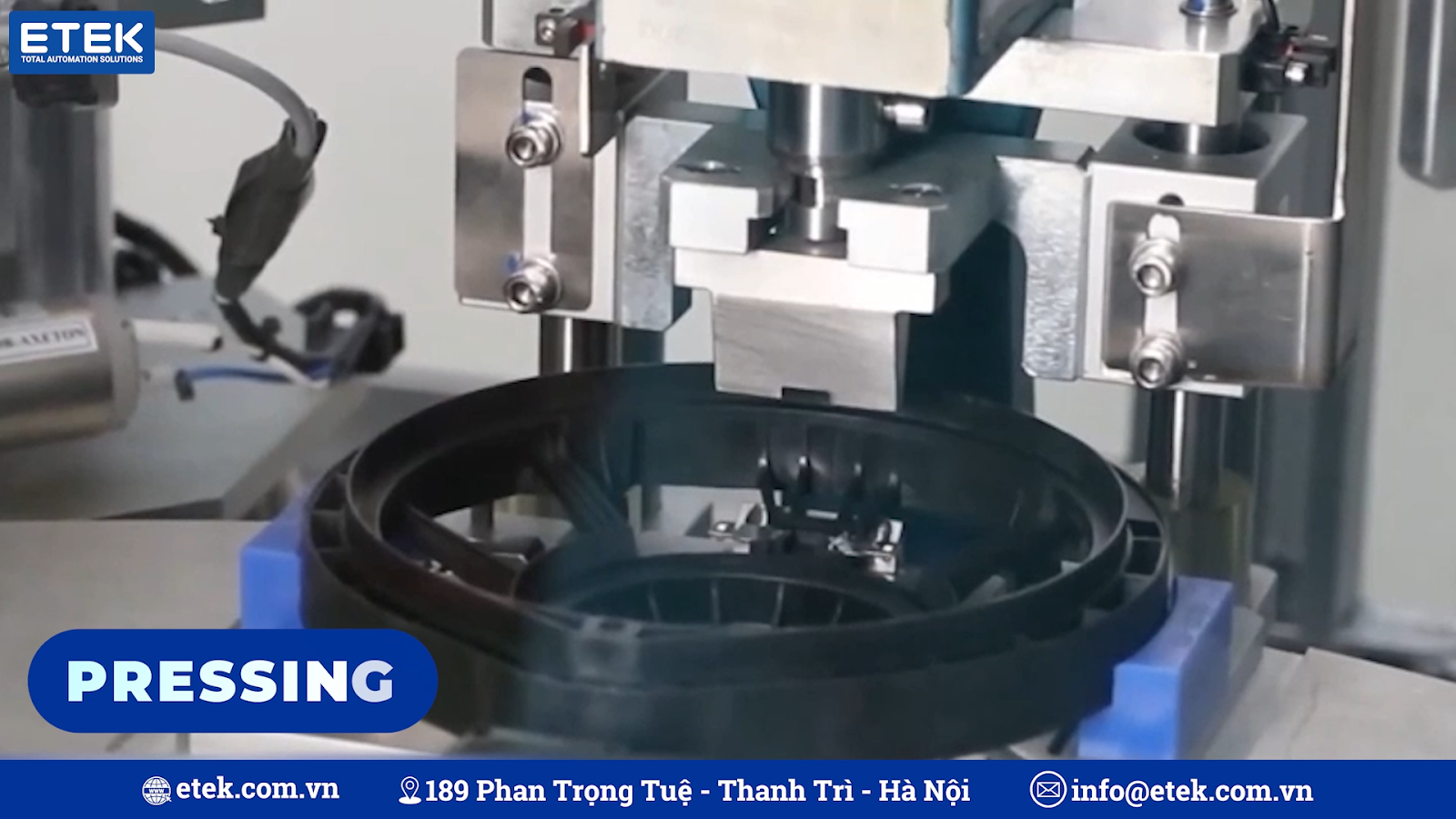

The process of pressing parts together using hydraulic, pneumatic, or servo-driven systems.

Benefits:

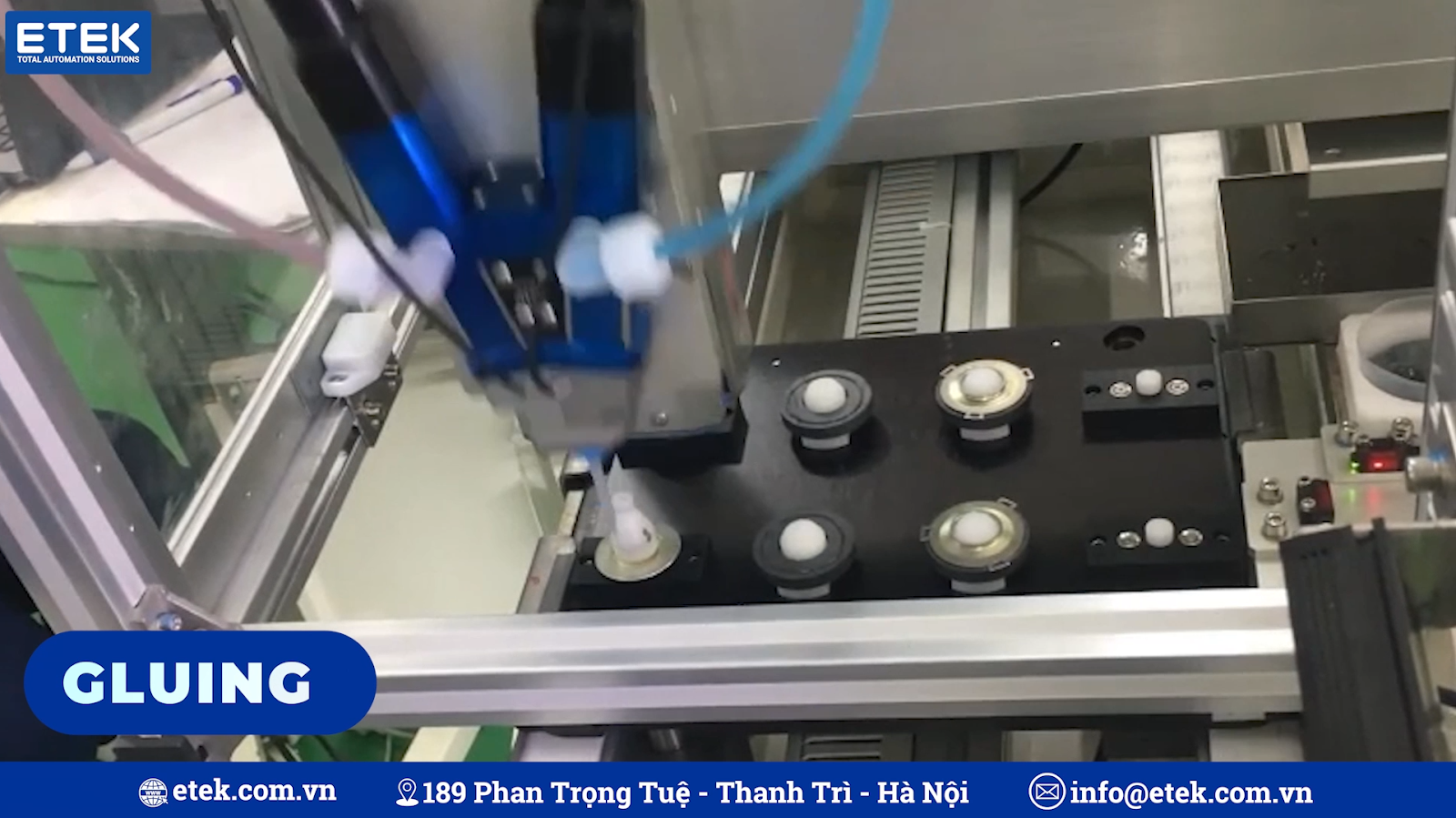

Gluing (epoxy, silicone, etc.) accurately along defined paths or spots using automatic dispensing machines.

Benefits:

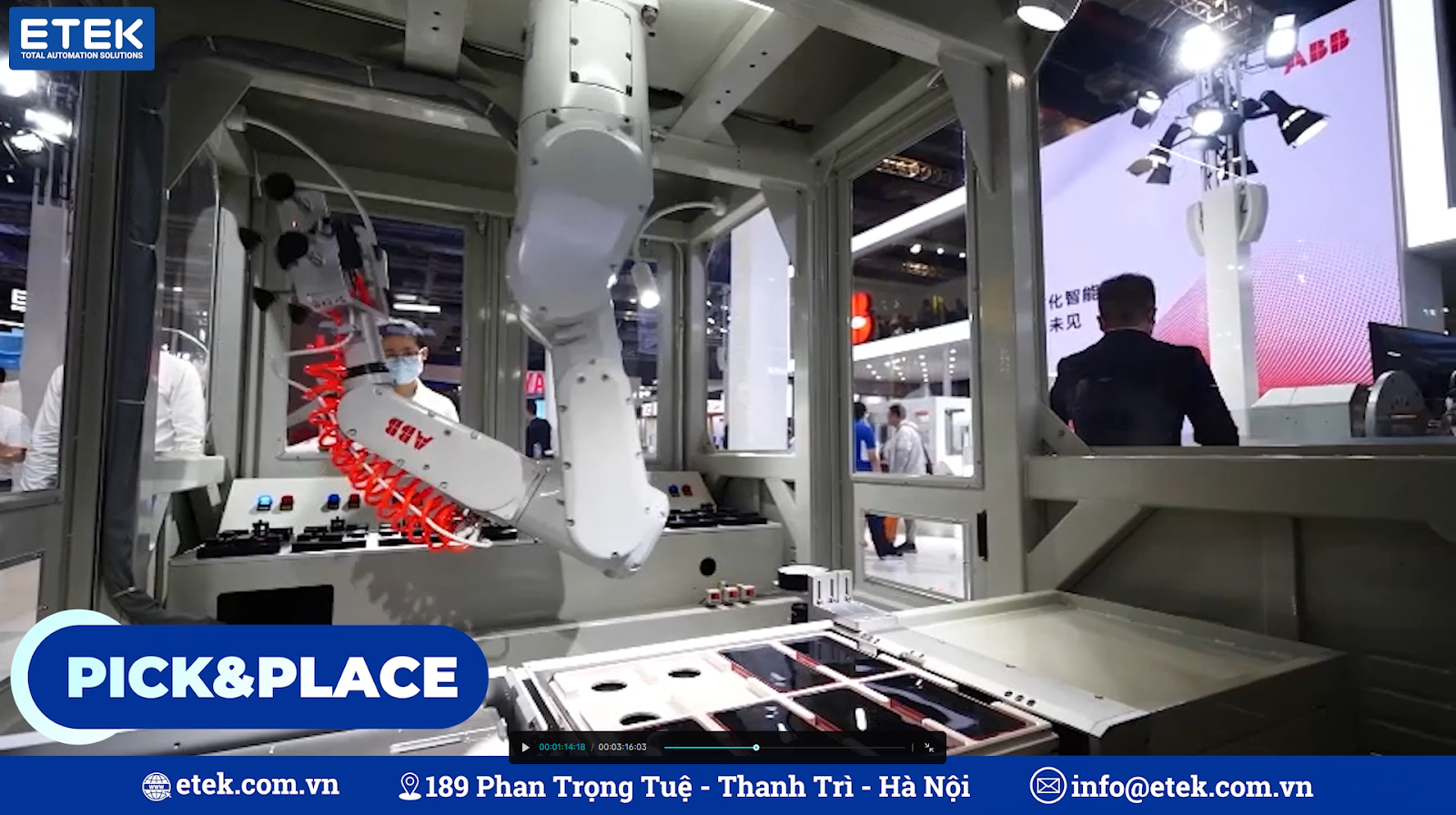

Robots automatically pick components from trays or conveyors and place them precisely in designated positions.

Benefits:

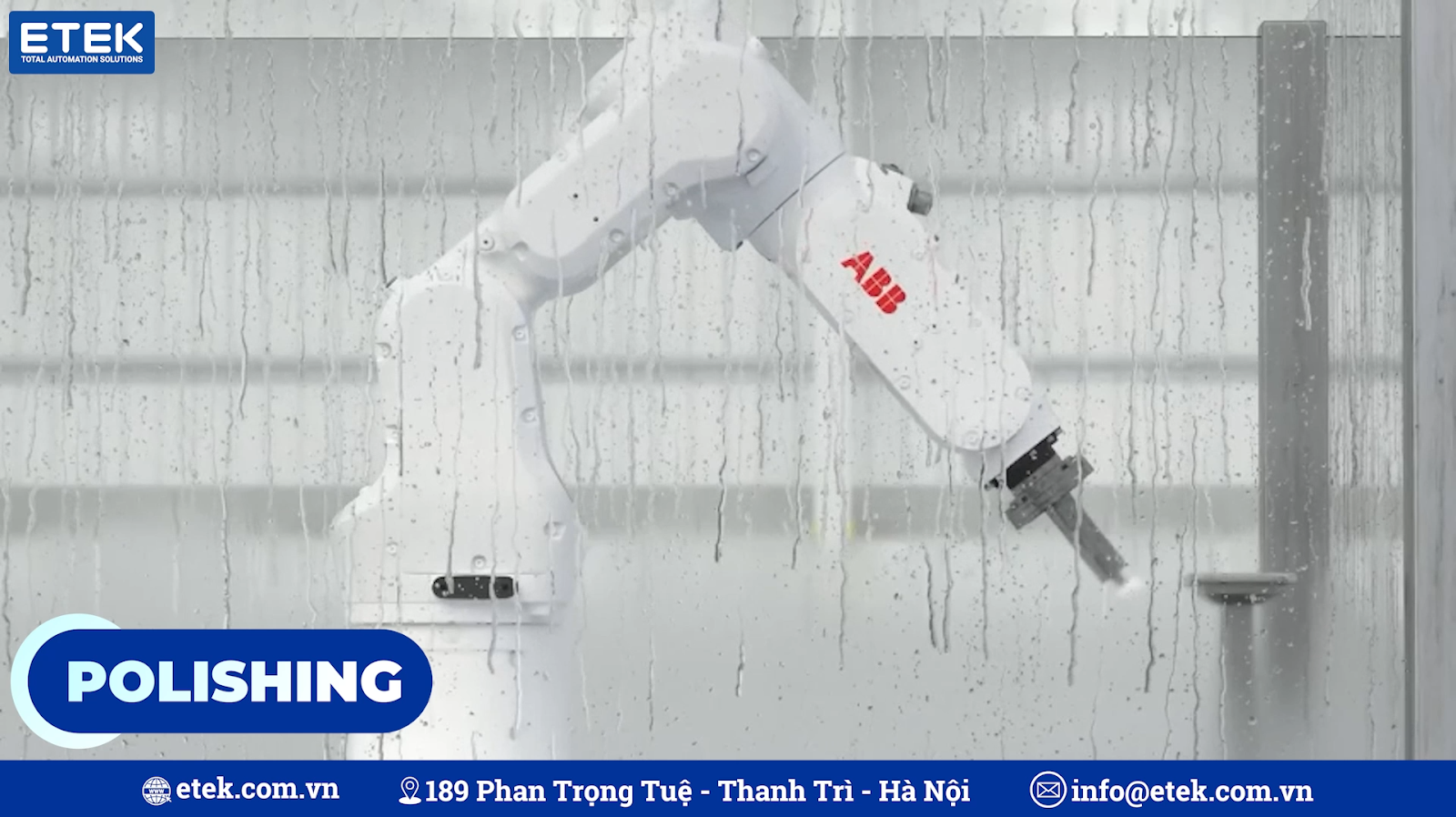

The process of smoothing and polishing product surfaces (plastic, aluminum, glass casings, etc.) using automated machines.

Benefits:

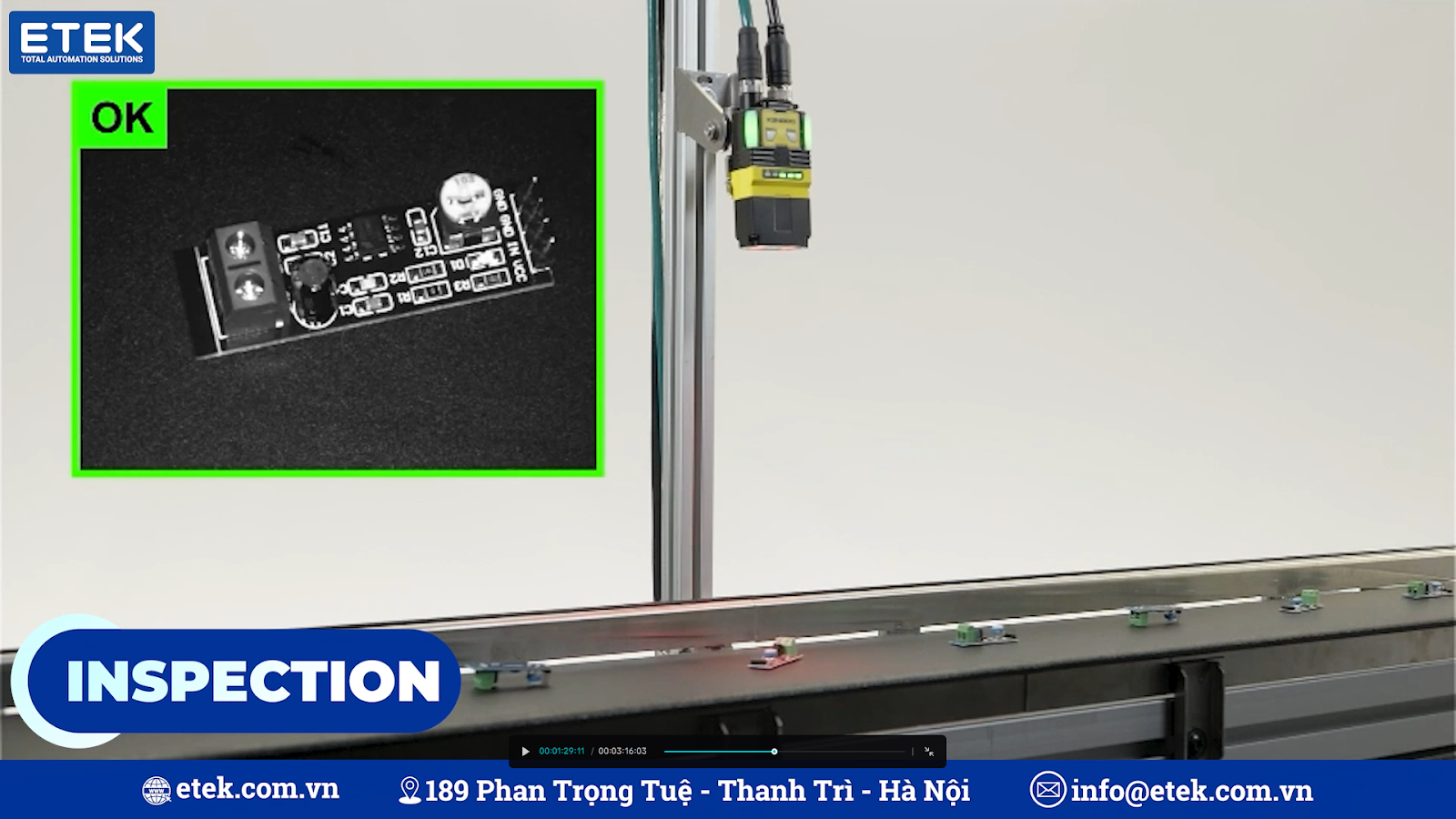

Using cameras, sensors, and image processing software to inspect shape, size, color, or circuitry.

Benefits:

Automated guided vehicles (AGVs) or autonomous mobile robots (AMRs) used to transport materials, components, or finished goods across production areas.

Benefits:

Pick to light: A system that uses LED lights to guide operators in selecting the correct components at workstations or storage areas.

Benefits:

Watch Video:

With nearly 20 years of experience in industrial automation and system integration, ETEK offers a complete ecosystem of solutions tailored to the specific needs of the electronics sector, from consultation, design, and integration to training and full life-cycle maintenance.

Looking to optimize your electronics production line? Let ETEK accompany you on the journey to build a smart, efficient, and modern factory

Hotline: (+84)965 800 166

Email: info@etek.com.vn

The high-density, high-speed, and flexible pallet storage system makes ETEK’s Automated Storage and Retrieval System (AS/RS) for pallets one of the most advanced automated warehousing solutions on the market. With…

Coding & Marking Solutions are integral technologies in modern manufacturing, ensuring product traceability, quality assurance, and compliance with industry standards. These solutions involve the application of marks, codes, or labels—such…

What is automation in the automotive industry? Automotive automation refers to the use of advanced technology in the manufacturing process or products to transfer part or all of the tasks…

In the era of industry 4.0, automation is no longer an option but has become an inevitable trend. For mechanical factories, steel structures, automobiles and motorbikes, arc welding processes requiring…